A method for sealing cracks in airport cement concrete pavement

A technology of cement concrete and cracks, which is applied in the field of crack sealing, can solve the problems of ineffective sealing of tiny cracks, affecting the smoothness of pavement, and prone to cracking, etc., achieves wide practicability, improves the rate of crack sealing, Easy to fully absorb water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The method for plugging up the crack of airport cement concrete pavement comprises the following steps:

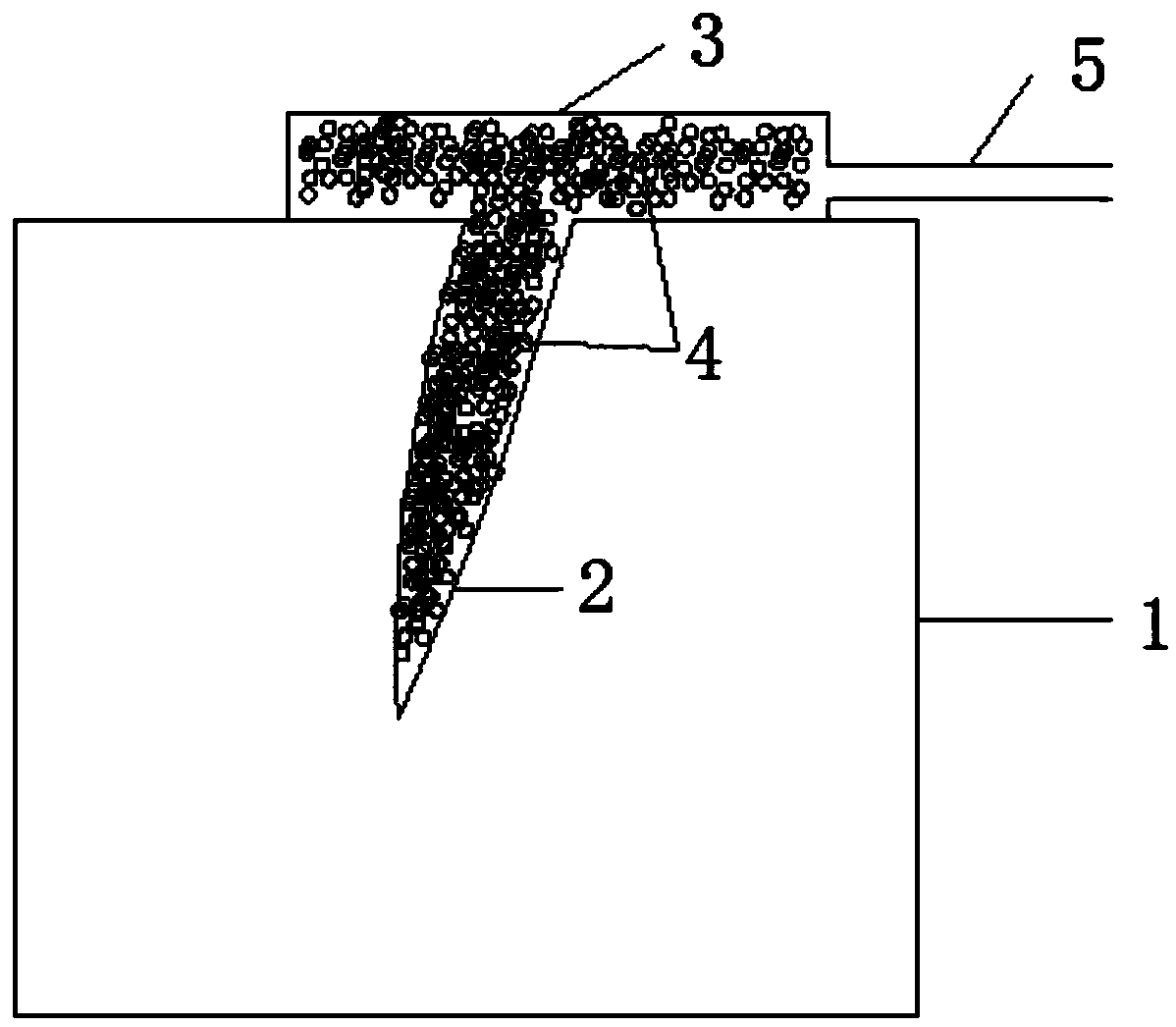

[0026] (1) Use the crack width detector to comprehensively investigate the crack 2 of the airport cement concrete pavement 1, and guide the formulation of the crack 2 plugging scheme. Slowly inject liquid nitrogen along the expansion direction of the crack 2 until it fills the crack, and complete the cleaning of the crack by gasification of liquid nitrogen;

[0027] (2) adopt spray mode to inject water in the fissure 2 of airport cement concrete pavement 1, the hydraulic pressure of spraying process to the fissure 2 of airport cement concrete pavement 1 is 0.4MPa, and standing time is 15min;

[0028] (3) Use high-strength natural curing adhesive to bond the covering device 3 on the airport cement concrete pavement 1 where the crack 2 is located to form a relatively closed space blocked by the crack 2, and place the solid particle material delivery pipe 5 at one end ...

Embodiment 2

[0034] The method for plugging up the crack of airport cement concrete pavement comprises the following steps:

[0035] (1) Use the crack width detector to comprehensively investigate the crack 2 of the airport cement concrete pavement 1, and guide the formulation of the crack 2 plugging scheme. Slowly inject liquid nitrogen along the expansion direction of the crack 2 until it fills the crack, and complete the cleaning of the crack by gasification of liquid nitrogen;

[0036](2) Water injection is carried out in the crack 2 of the airport cement concrete pavement 1 by means of spraying. The hydraulic pressure of the water injection in the crack 2 of the airport cement concrete pavement 1 during the spraying process is 0.8MPa, and the standing time is 20min;

[0037] (3) Use high-strength natural curing adhesive to bond the covering device 3 on the airport cement concrete pavement 1 where the crack 2 is located to form a relatively closed space blocked by the crack 2, and plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com