A kind of preparation method of high-sensitivity ethanol gas sensor

A gas sensor and high-sensitivity technology, applied in the field of gas sensor preparation, can solve problems such as burden and energy consumption, and achieve the effects of short response time, low working temperature and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

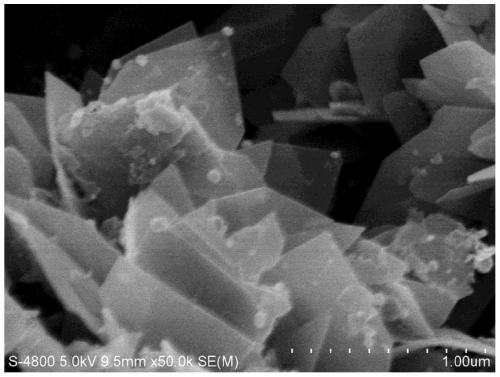

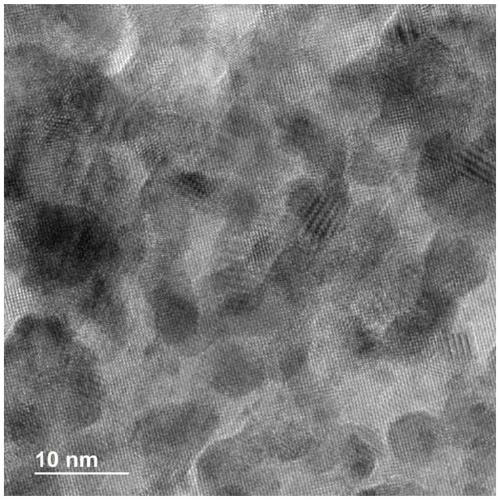

[0019] Example 1 Preparation of Sn 3 o 4 square material

[0020] Dissolve 0.276g of salicylic acid in 20ml of high-purity water and ethanol mixed solvent (V water: V ethanol = 1:1), stir until completely dissolved, then add 7ml of NaOH solution (1mol / L) to the solution. 0.339g SnCl 2 ▪H 2 O was dissolved in 10ml of high-purity water and stirred until dissolved. Configured SnCl 2 The solution was added dropwise to the solution prepared with salicylic acid under the condition of stirring. After stirring for 30 minutes, put it into a 50ml polytetrafluoroethylene hydrothermal reaction kettle, put the reaction kettle at 150°C for 16 hours and cool to obtain a light yellow precipitate , the obtained light yellow precipitate was centrifuged and washed 6 times with high-purity water and absolute ethanol under the condition of 8000rmp to obtain a light yellow sample, and the obtained light yellow sample was dried at 60°C for 4h to prepare layered Sn 3 o 4 Square material.

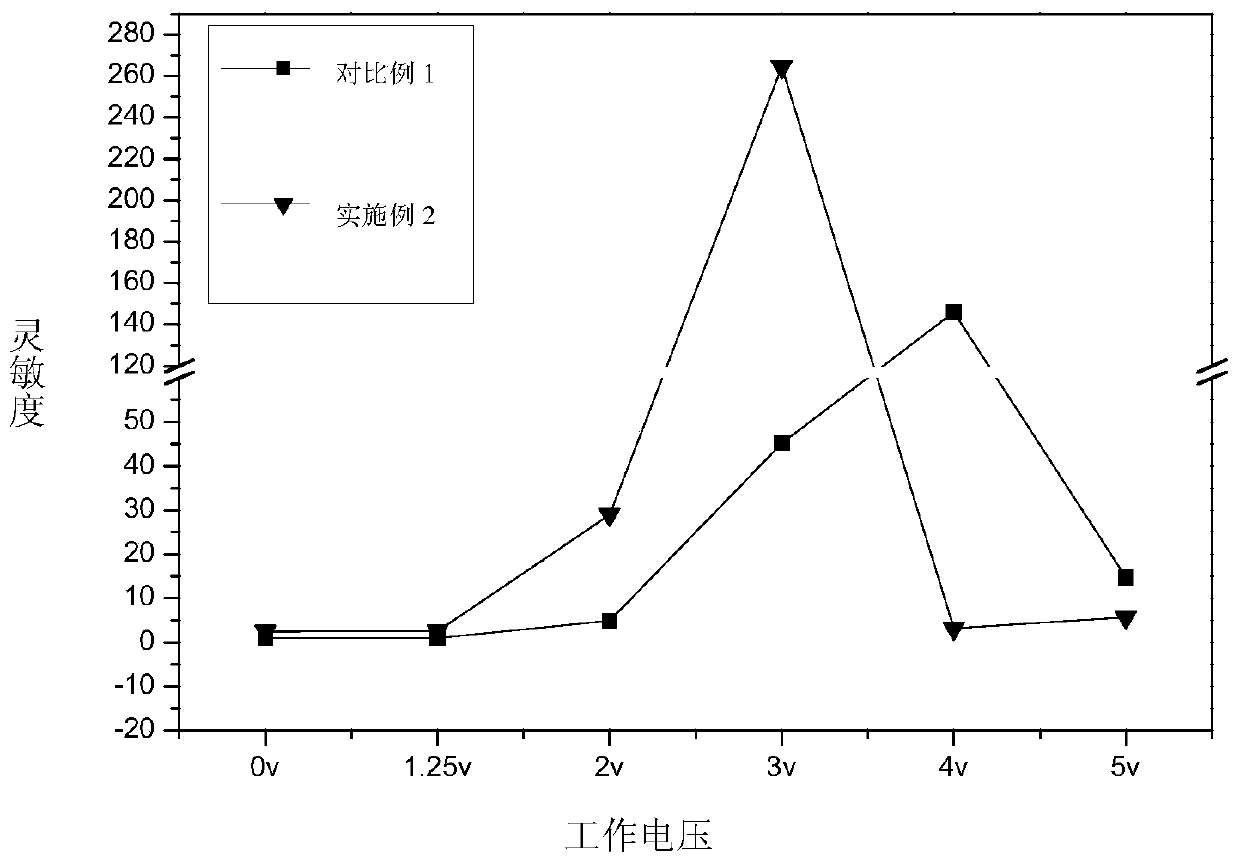

Embodiment 2

[0022] A preparation method of a high-sensitivity ethanol gas sensor, comprising the following steps: Step 1, taking 30mgSn 3 o 4 Mix the square sheet material with 10ml of ethylene glycol, stir evenly, add 10mg of polyvinylpyrrolidone, continue to stir, then drop in 0.077mmol of tetrachloroplatinic acid solution, and stir to obtain the first mixture; step 2, transfer the first mixture In the ark, after drying at 200°C for 2 hours together with the ark, transfer the samples in the ark to a tube furnace for sintering at 500°C, and sinter for 4 hours to obtain a semi-finished product; step 3, after mixing the semi-finished product with deionized water, Then spread evenly on the alumina / Au electrode, after drying, put it in a tube furnace and sinter to 500°C, and sinter for 4 hours to get the electrode; step 4, weld the electrode on the electrode base to complete the gas sensor preparation. Wherein, the sintering temperature of the tube furnace in step 2 and step 3 is both 500°...

Embodiment 3

[0024] A kind of preparation method of high-sensitivity ethanol gas sensor, comprises the following steps: Step 1, take 45mgSn 3 o 4 Mix the square sheet material with 20ml of glycerin, stir well, add 10mg of polyvinylpyrrolidone, continue to stir, then drop in 0.005mmol of chloroplatinic acid solution, and stir to obtain the first mixture; step 2, transfer the first mixture to the ark, After drying in an oven at 300°C for 2 hours, transfer the sample in the ark to a tube furnace for sintering to 500°C, and sinter for 4 hours to obtain a semi-finished product; step 3, mix the semi-finished product with an appropriate amount of deionized water, and coat it evenly On the alumina / Au electrode, after drying, place it in a tube furnace and sinter to 500°C for 2 hours to obtain an electrode; step 4, weld the electrode on the electrode base to complete the preparation of the gas sensor. Wherein, the sintering temperature of the tube furnace in step 2 and step 3 is both 500° C., and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com