Polyvinylidene fluoride microporous membrane prepared by gel extrusion casting method

A technology of melt extrusion and process method, which is applied in the field of polyvinylidene fluoride microporous film preparation by gel extrusion casting method, can solve the problems of large solvent volatilization and low solid content, and achieve low solvent consumption and solid The effect of high content and uniform film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

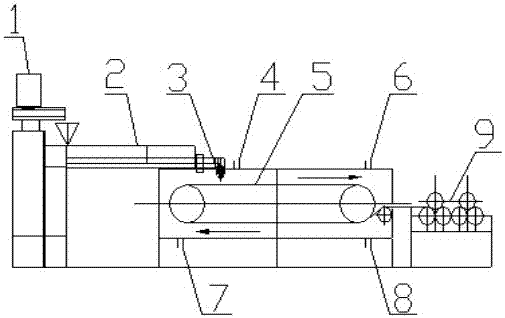

Image

Examples

Embodiment 1

[0034] Add 2 kg N,N-dimethylacetamide (DMAC) to 10 kg PVDF, and stir at room temperature to form a uniform gel. After that, the gel is added to the metering feeder of the extruder, plasticized and melted in the screw extruder at 200-215°C, and cast through the die on a steel belt rotating at a constant speed at 80°C. Membrane, steel belt speed is 3 rev / min. After the continuously heated steel strip is dried, it is wound up into a film by a winder, and finally the finished microporous film is obtained. The thickness of the film is 20 µm, and the thickness tolerance in the longitudinal and transverse directions is less than 0.5 µm. The pore size of the micropores is 2-5 µm, the porosity is 43%, and the water flux under the pressure of 0.1 MPa is 180 L / m2•h.

Embodiment 2

[0036] Add 2 kg N, N-dimethylformamide (DMF) to 10 kg PVDF, and stir at room temperature to form a uniform gel. After that, the gel is added to the metering feeder of the extruder, plasticized and melted in the screw extruder at 200-215°C, and cast through the die on a steel belt rotating at a constant speed at 70°C. Membrane, steel belt speed is 3 rev / min. After the continuously heated steel strip is dried, it is wound up into a film by a winder, and finally the finished microporous film is obtained. The thickness of the film is 20 µm, the thickness tolerance in the vertical and transverse directions is less than 0.5 µm, the pore size of the micropore is 2-5 µm, the porosity is 40%, and the water flux under the pressure of 0.1MPa is 175L / m2•h.

Embodiment 3

[0038] Add 2 kg of N-methylpyrrolidone (NMP) to 10 kg of PVDF, and stir at room temperature to form a uniform gel. Then the gel is added to the metering feeder of the extruder, plasticized and melted and extruded in the screw extruder at 200-215 ° C, and cast on a steel belt rotating at a constant speed of 100 ° C through the die die. Membrane, steel belt speed is 3 rev / min. After being dried by the continuously heated steel strip, it is wound up into a film by a winder, and finally the finished microporous film is obtained. The thickness of the film is 20 µm, the thickness tolerance in the vertical and transverse directions is less than 0.5 µm, the micropore diameter is 2-5 µm, the porosity is 50%, and the water flux under the pressure of 0.1MPa is 195 L / m2•h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com