Preparation method of superparamagnetic hollow ferroferric oxide microspheres

A triiron tetroxide and superparamagnetic technology, applied in the direction of iron oxide/iron hydroxide, ferrous oxide, diamagnetic/paramagnetic materials, etc. Amplify the use and other problems to achieve the effect of good catalytic performance, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

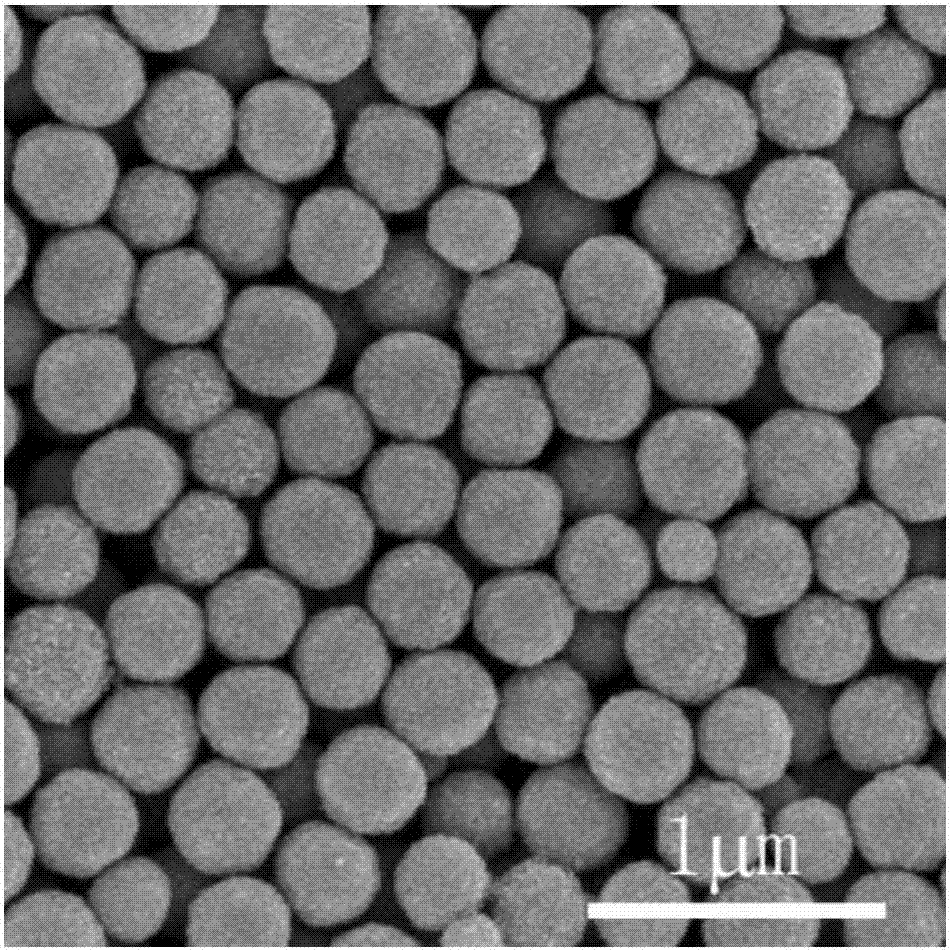

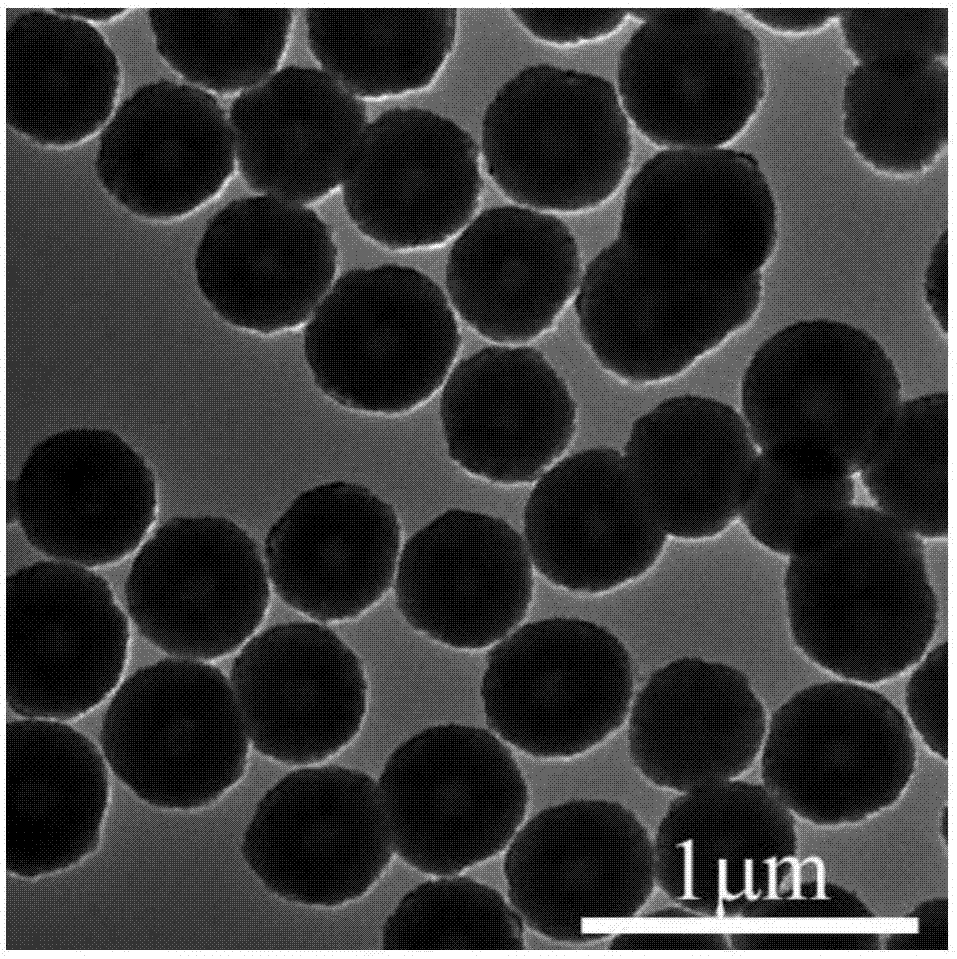

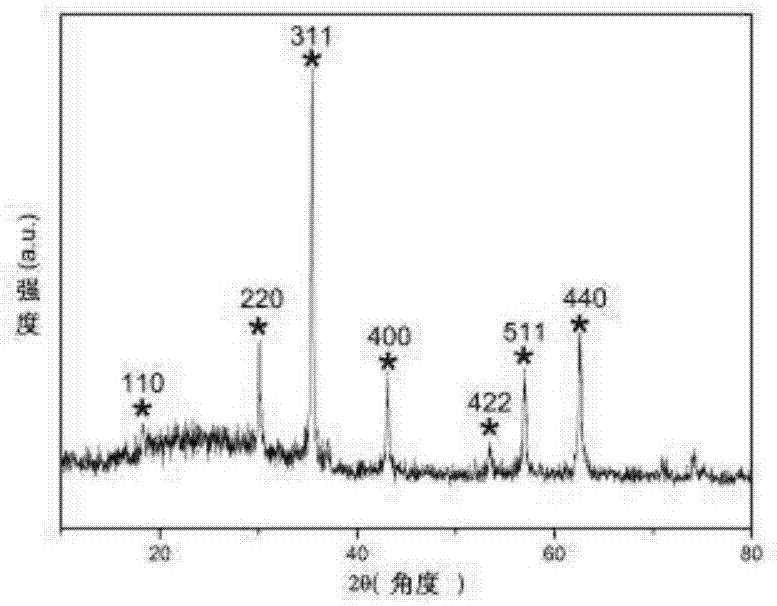

[0027] A method for preparing superparamagnetic hollow ferric oxide microspheres, characterized in that it comprises the following steps: step 1, dissolving ferric nitrate nonahydrate and anhydrous sodium acetate into ethylene glycol, and adding polystyrene sulfonate Sodium acid, stirring to form a mixed solution; step 2, reacting the above mixed solution for a certain period of time under solvothermal conditions, magnetic separation, and post-treatment to obtain superparamagnetic hollow ferric oxide microspheres.

[0028] The above is the core of the present invention, and the superparamagnetic hollow iron ferric oxide microspheres are prepared in one step by using ferric nitrate nonahydrate, anhydrous sodium acetate, ethylene glycol and sodium polystyrene sulfonate as raw materials. The raw materials used in the present invention are easy to obtain and the cost is low, and the hollow iron ferric oxide microspheres are prepared by a one-step method. Paramagnetic properties. ...

Embodiment 2

[0034] A method for preparing superparamagnetic hollow ferric oxide microspheres, characterized in that it comprises the following steps: step 1, dissolving ferric nitrate nonahydrate and anhydrous sodium acetate into ethylene glycol, and adding polystyrene sulfonate Sodium acid, stirring to form a mixed solution; step 2, reacting the above mixed solution for a certain period of time under solvothermal conditions, magnetic separation, and post-treatment to obtain superparamagnetic hollow ferric oxide microspheres.

[0035] Specifically, in step 1, dissolve 2.7g of ferric nitrate nonahydrate in 40mL of ethylene glycol, dissolve 7.2g of anhydrous sodium acetate in 40mL of ethylene glycol, and add the ethylene glycol solution of anhydrous sodium acetate to nitric acid nonahydrate Iron glycol solution, continue to mix and stir evenly to form a mixed solution; dissolve 0.0675g of sodium polystyrene sulfonate in 5mL of water, and add the aqueous solution of sodium polystyrene sulfona...

Embodiment 3

[0039] A preparation method of superparamagnetic hollow iron ferric oxide microspheres, characterized in that it comprises the following steps: step 1, dissolving 2.7g ferric nitrate nonahydrate in 40mL ethylene glycol, dissolving 7.2g anhydrous sodium acetate Add the ethylene glycol solution of anhydrous sodium acetate to the ethylene glycol solution of ferric nitrate nonahydrate in 40mL of ethylene glycol, and continue to mix and stir evenly to form a mixed solution; dissolve 0.54g of sodium polystyrene sulfonate in 2mL of water, and the aqueous solution of sodium polystyrene sulfonate was added to the above mixed solution, and vigorously stirred for 30 to 120 minutes to form a uniform and clear mixed solution, wherein the mass ratio of ferric nitrate nonahydrate to anhydrous sodium acetate was 1:3, the solid-liquid ratio of ferric nitrate nonahydrate and ethylene glycol is 1g: 30mL, the solid-liquid ratio of anhydrous sodium acetate and ethylene glycol is 1g: 11mL; The sodium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com