A kind of preparation method of imine water-removing agent

A technology of water agent and imine, which is applied in the field of preparation of imine water remover, can solve the problems of high crosslinking degree, poor coating performance, high consumption, etc., achieve stable storage performance, obvious physical properties, and realize way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Step 1. Add 228g of cyclohexanediamine (2 moles) in a 500ml three-neck flask equipped with a stirrer, thermometer, condenser and constant pressure funnel, and add 53g of acrylonitrile (1 mole) dropwise to the system through the constant pressure funnel within 1h. ), control the dropping temperature at 30±2°C, continue stirring for 1 h after the dropping, and remove excess cyclohexanediamine by vacuum distillation to obtain N-propionitrile-cyclohexanediamine;

[0020] Step 2. Add 167g of N-propionitrile-cyclohexanediamine (1 mole) prepared in step 1 to a 500ml three-neck flask equipped with a stirrer, thermometer, condenser and constant pressure funnel, and enter the system through the constant pressure funnel for 2h Add 120g (1 mole) of acetophenone dropwise to the medium, control the dropping temperature at 35±2°C, continue stirring for 1h after the dropping, and remove the generated water by vacuum distillation to obtain the desired imine water-removing agent. Keep ai...

Embodiment 2

[0022] Step 1, add 148g of 1,2-propanediamine (2 moles) in a 500ml three-neck flask equipped with a stirrer, thermometer, condenser and constant pressure funnel, and drop 2-butane into the system through the constant pressure funnel within 1h Acrylonitrile 67g (1 mole), control the dropwise addition temperature at 30±2°C, continue to stir for 1h after the dropwise addition, and remove excess 1,2-propylenediamine by vacuum distillation to obtain N-butyronitrile-1,2 Propylenediamine;

[0023] Step 2, in the 500ml there-necked flask that stirrer, thermometer, condenser and constant pressure funnel are equipped with, add the N-butyronitrile-1 that 141g step 1 makes, 2 propanediamine (1 mole), through constant pressure funnel Add 72g (1 mole) of n-butyraldehyde dropwise to the system within 2h, control the dropping temperature at 35±2°C, continue stirring for 1h after the dropwise addition, remove the generated water by vacuum distillation, and obtain the desired imine dehydration ...

Embodiment 3

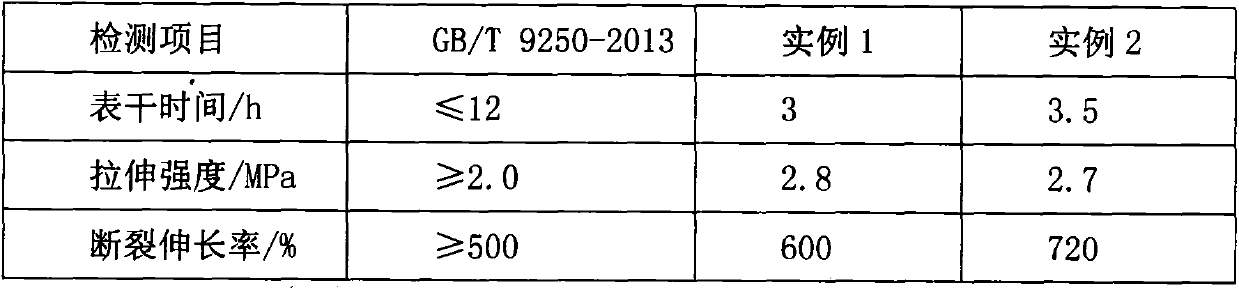

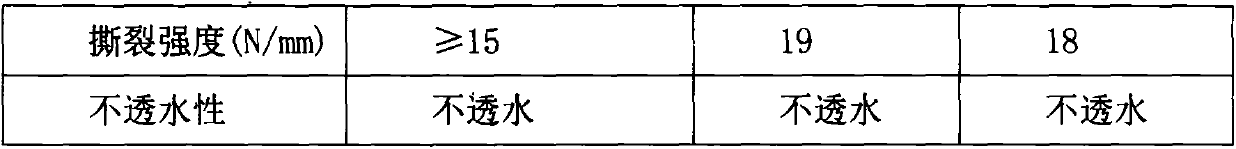

[0025] The imine water-removing agent prepared by example 1 and example 2 is applied to polyurethane waterproof coating, and the specific reference formula (parts by mass) and operation steps are as follows:

[0026] Table 1 One-component polyurethane waterproof coating formula

[0027] Polyether 2000 140 Polyether 3050 60 Dispersant KH550 0.4 Chlorinated Paraffin 52 100 Kaolin 140 Heavy calcium (800 mesh) 320 TDI 34 No. 120 solvent 120 Organotin 0.7 The dewatering agent that embodiment 1 prepares 17.5 The dewatering agent that embodiment 2 prepares 13

[0028] Add polyether, dispersant, chlorinated paraffin 52 to a three-necked flask and heat to 120-130°C, slowly add kaolin and heavy calcium, vacuum dehydrate at 120-130°C for 2 hours, add TDI and solvent when the temperature is lowered to 90°C, 80°C React for 2 hours, add organotin and continue to react at 80°C for 1 hour, divide the reacted liquid into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com