Coating process suitable for three-layer anti-reflection coating of polycrystalline solar cells

A technology of solar cells and anti-reflection coatings, applied in the field of solar cells, can solve the problems of high reflectance of solar cells, complicated preparation process, high rework rate, etc., and achieve the effects of uniform coating color, reduced rework rate, and high product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

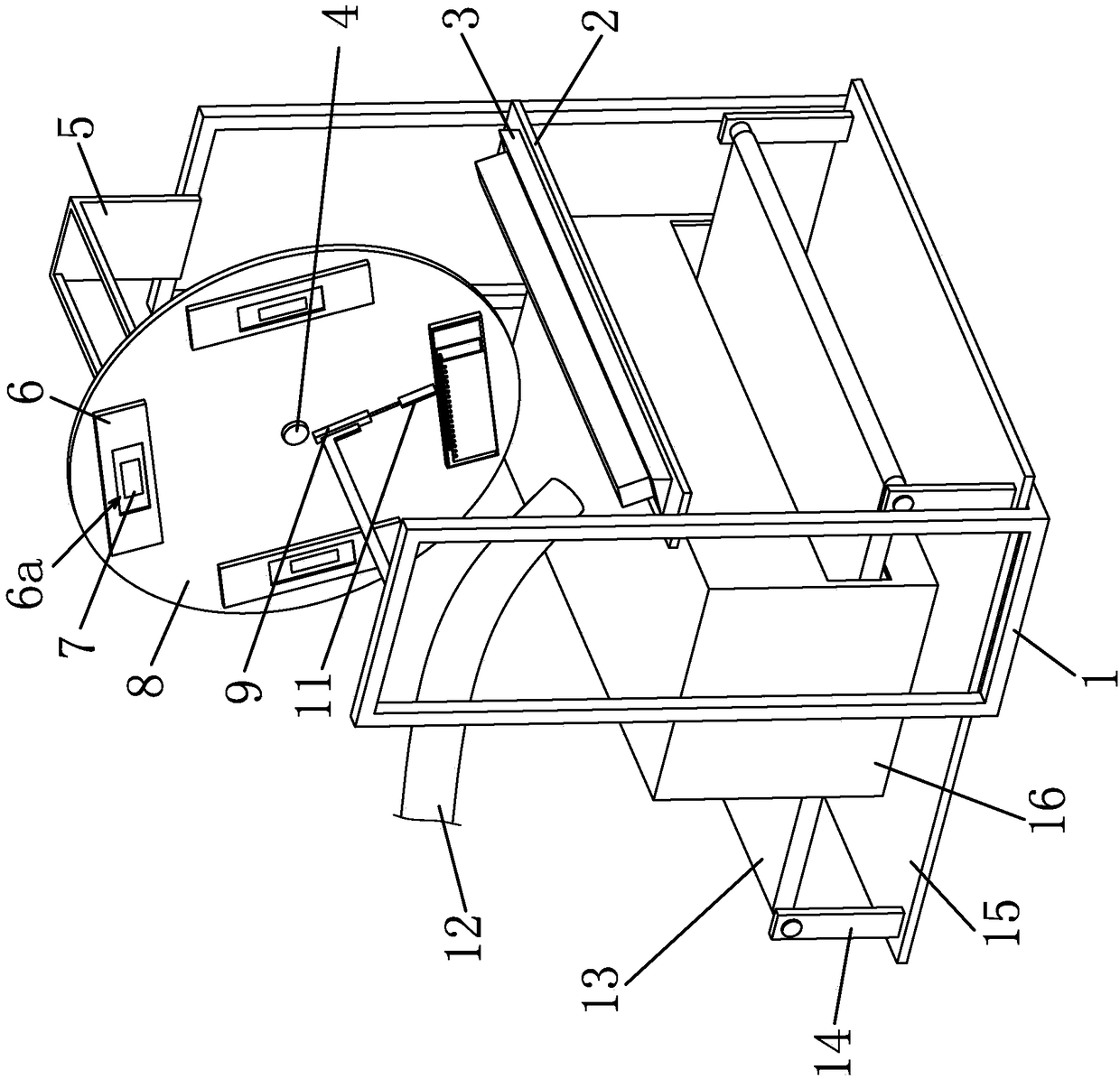

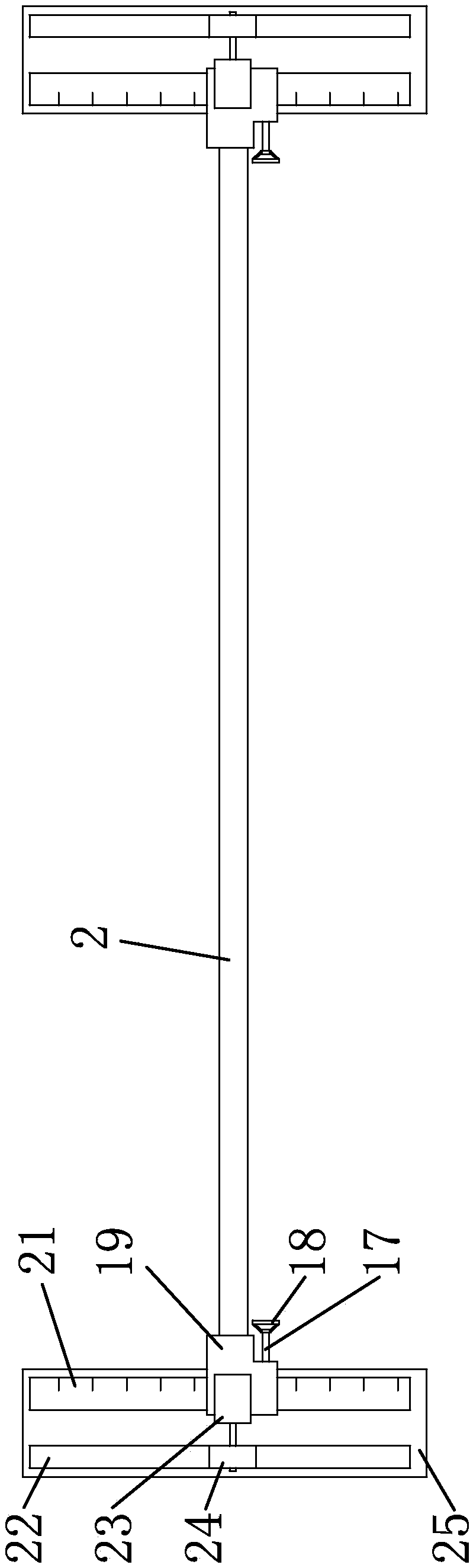

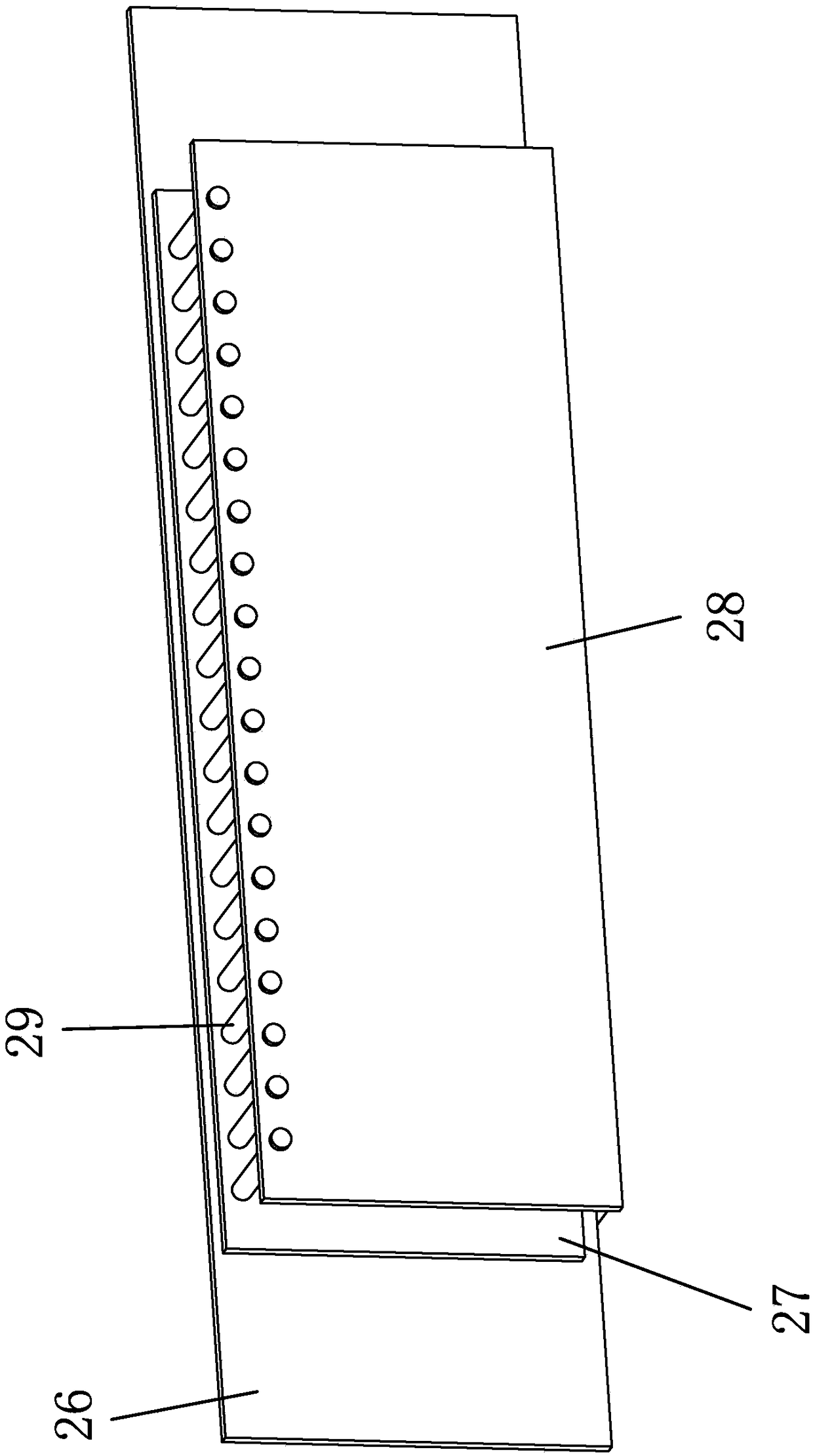

[0048] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0049] This is applicable to the coating process of three-layer anti-reflection film for polycrystalline solar cells, including the following steps:

[0050] a. Clean and texture the crystalline silicon wafer, diffuse and etch, and generate a layer of 1-2nm SiO on the surface of the crystalline silicon wafer through an ozone generator 2 Oxide film; in this embodiment, the crystalline silicon wafer is cleaned and textured, diffused and etched, and a layer of 1.5nm SiO is formed on the surface of the crystalline silicon wafer by an ozone generator. 2 Oxide film can increase its resistance to sodium ion penetration, prevent ions and water vapor from entering the battery, and damage the performance of the battery;

[0051] b....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com