MoS2/carbon fiber network flexible electrode and preparation method and application thereof

A technology of molybdenum disulfide and flexible electrodes, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of not meeting the requirements of flexible lithium-ion batteries, poor electrode flexibility, and cumbersome preparation processes, etc., and is suitable for mass production, It is not easy to fall off and the effect of simplifying the process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

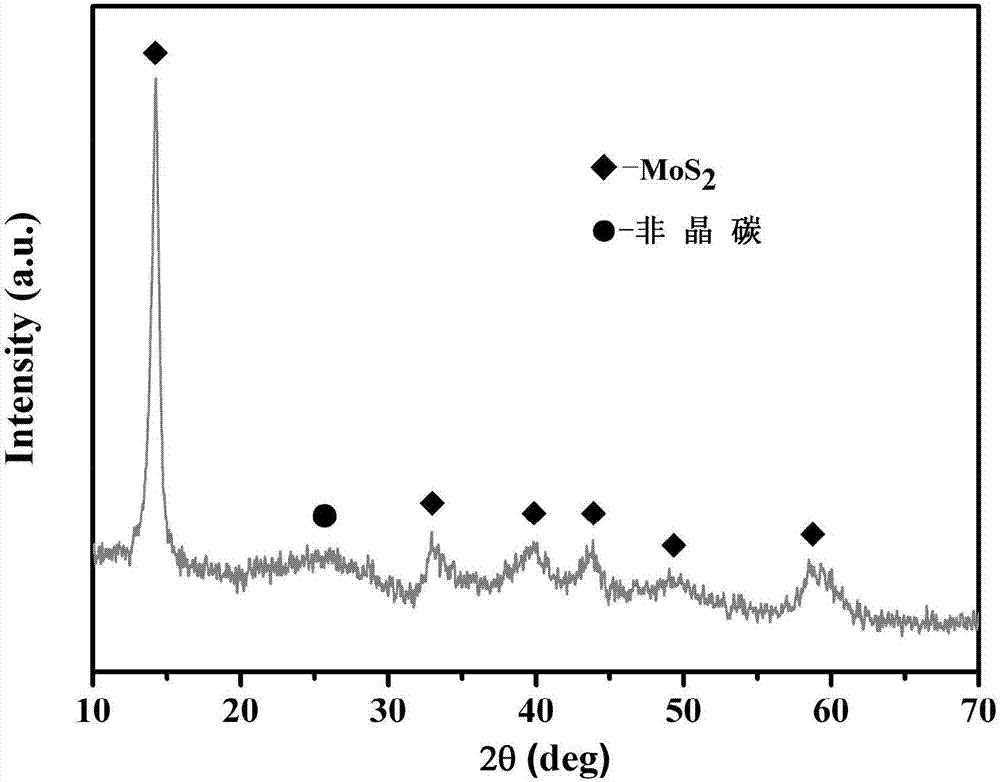

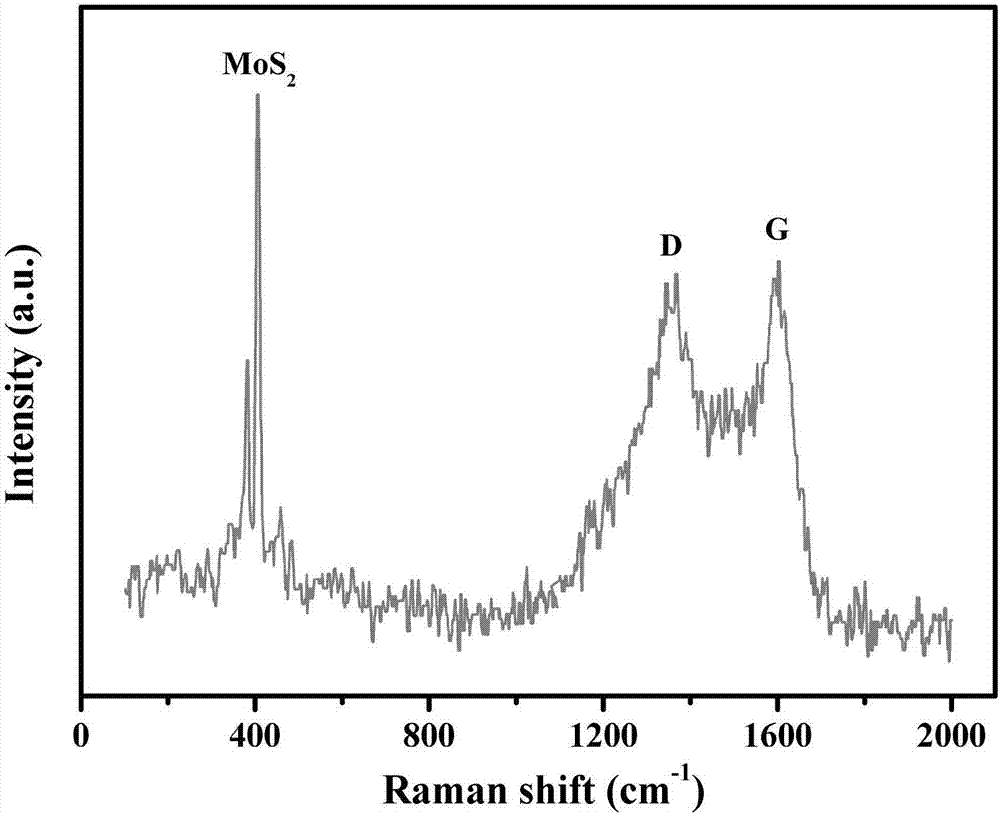

Embodiment 1

[0046] Weigh 0.1960g of ammonium molybdate and 0.1903g of thiourea, add them to 5mL of deionized water successively, carry out magnetic stirring at a stirring speed of 200r / min to dissolve them into a solution, and then sonicate for 15min with an ultrasonic machine with a power of 320W Mix it well. Take the pre-cut Hangzhou Fuyang Xinxing slow-speed quantitative filter paper disk with a diameter of 19mm and immerse it in the above mixture, and use an ultrasonic device with a power of 320W for 30 minutes, and then in 10 -1 Pa stand in a vacuum box for 12 hours. The above-mentioned fully soaked filter paper discs were frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -50°C for 30 hours in vacuum to obtain a filter paper disc containing a mixture of molybdenum source and sulfur source airgel. Then put it in a porcelain boat, put the porcelain boat into the constant temperature zone of the tube furnace, first pass in 300mL / min argon gas for 30min to remo...

Embodiment 2

[0050] Weigh 0.2059g of sodium molybdate and 0.3806g of thiourea, add them to 2mL of deionized water successively, carry out magnetic stirring at a stirring speed of 200r / min to dissolve them into a solution, and then sonicate them with a 320W ultrasonic machine for 15min Mix it well. Take the pre-cut Hangzhou Fuyang Xinxing medium-speed quantitative filter paper disk with a diameter of 14mm and immerse it in the above mixture, and use an ultrasonic device with a power of 320W for 30 minutes, and then in 10 -1 Pa stand in a vacuum box for 12 hours. The above-mentioned fully soaked filter paper disks were frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -80°C for 24 hours in vacuum to obtain a filter paper disk containing a mixture of molybdenum source and sulfur source airgel. Then put it in a porcelain boat, put the porcelain boat into the constant temperature zone of the tube furnace, first pass in 500mL / min argon gas for 20min to remove the air, ...

Embodiment 3

[0053] Weigh 0.1960g of ammonium molybdate and 0.1878g of thioacetamide, add them to 3mL of deionized water successively, carry out magnetic stirring at a stirring speed of 200r / min to dissolve them into a solution, and then use a 320W ultrasonic Sonicate for 15 minutes to make it evenly mixed. Take the pre-cut Hangzhou Fuyang Xinxing slow quantitative filter paper disk with a diameter of 14mm and immerse it in the above mixture, sonicate with a power 320W ultrasonic machine for 30min, then in 10 -1 Pa stand in a vacuum box for 12 hours. The above-mentioned fully soaked filter paper discs were frozen in a refrigerator for 12 hours, and then placed in a freeze dryer at -50°C for 24 hours in vacuum to obtain a filter paper disc containing a mixture of molybdenum source and sulfur source airgel. Then put it in a porcelain boat, put the porcelain boat into the constant temperature zone of the tube furnace, first pass 200mL / min nitrogen gas for 30min to remove the air, then pass 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com