Preparation method for graphene/stannic oxide sandwich-structured thin film on surface of aluminium alloy bipolar plate

A tin dioxide and bipolar plate technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of stainless steel corrosion resistance not greatly improved, harsh preparation conditions, etc., to achieve good corrosion resistance , the preparation process is simple, the effect of excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A method for preparing a graphene / tin dioxide sandwich film on the surface of an aluminum alloy bipolar plate, comprising the steps of:

[0049] (1) Preparation of etching solution

[0050] Prepare a NaOH solution with a concentration of 1M as an etching solution;

[0051] (2), the preparation of PDDA aqueous solution

[0052] Configure a PDDA aqueous solution with a volume ratio of 1% for self-assembly;

[0053] (3), preparation of graphene oxide aqueous solution

[0054] Configuration mass fraction is the graphene oxide aqueous solution of 1wt%, is used for self-assembly;

[0055] (4) Preparation of hydrothermal precursor solution

[0056] According to the volume ratio of deionized water and absolute ethanol is 3:1, mix 30mL deionized water and 10mL absolute ethanol respectively, then add 0.15g of stannous chloride dihydrate, mix well, adjust the solution with 1M NaOH The pH=9~10;

[0057] (5), pretreatment of aluminum alloy

[0058] 5 pieces (1, 2, 3, 4, 5) of...

Embodiment 2

[0068] In this embodiment, a method for preparing a graphene / tin dioxide sandwich structure film on the surface of an aluminum alloy bipolar plate specifically includes the following steps:

[0069] (1) Preparation of etching solution

[0070] Prepare a NaOH solution with a concentration of 1M as an etching solution;

[0071] (2), the preparation of PDDA aqueous solution

[0072] Configure a PDDA aqueous solution with a volume ratio of 1% for self-assembly;

[0073] (3), preparation of graphene oxide aqueous solution

[0074] Configuration mass fraction is the graphene oxide aqueous solution of 1wt%, is used for self-assembly;

[0075] (4) Preparation of hydrothermal precursor solution

[0076] According to the volume ratio of deionized water and absolute ethanol as 1:3, mix 10mL deionized water and 30mL absolute ethanol respectively, then add 0.15g of stannous chloride dihydrate, mix well, adjust the solution with 1M NaOH The pH=9~10;

[0077] (5), pretreatment of alumi...

Embodiment 3

[0086] In this embodiment, a method for preparing a graphene / tin dioxide sandwich structure film on the surface of an aluminum alloy bipolar plate specifically includes the following steps:

[0087] (1) Preparation of etching solution

[0088] Prepare a NaOH solution with a concentration of 1M as an etching solution;

[0089] (2), the preparation of PDDA aqueous solution

[0090] Configure a PDDA aqueous solution with a volume ratio of 1% for self-assembly;

[0091] (3), preparation of graphene oxide aqueous solution

[0092] Configuration mass fraction is the graphene oxide aqueous solution of 1wt%, is used for self-assembly;

[0093] (4) Preparation of hydrothermal precursor solution

[0094] According to the volume ratio of deionized water and absolute ethanol is 3:1, mix 30mL deionized water and 10mL absolute ethanol respectively, then add 0.15g of stannous chloride dihydrate, mix well, adjust the solution with 1M NaOH The pH=9~10;

[0095] (5), pretreatment of alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

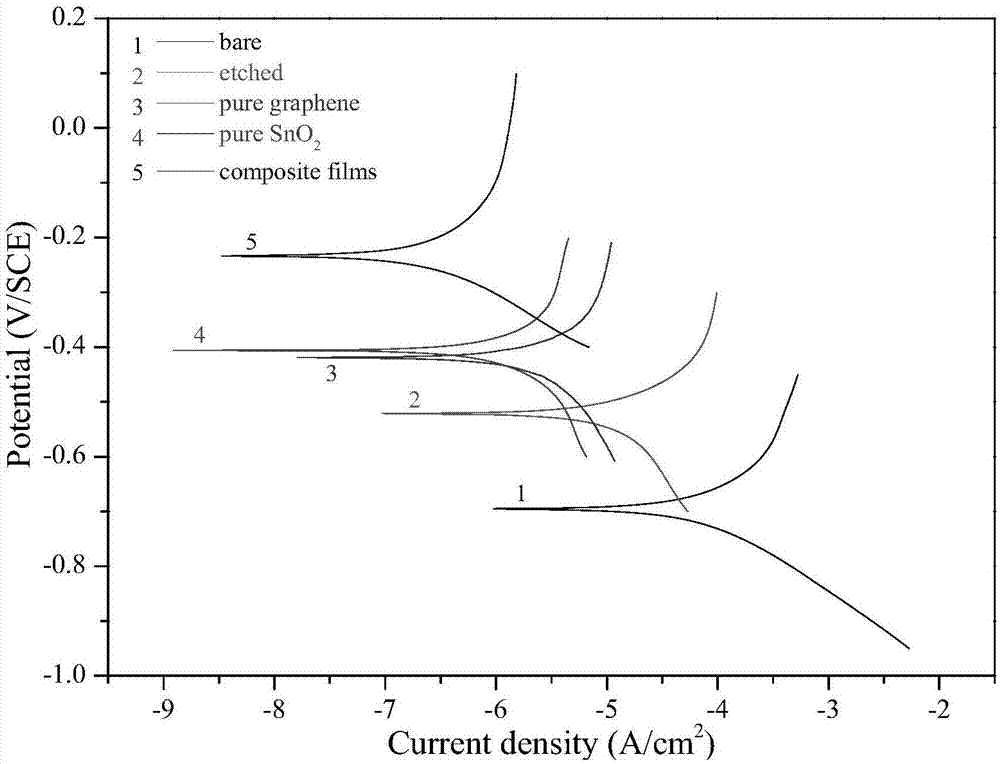

| Corrosion current density | aaaaa | aaaaa |

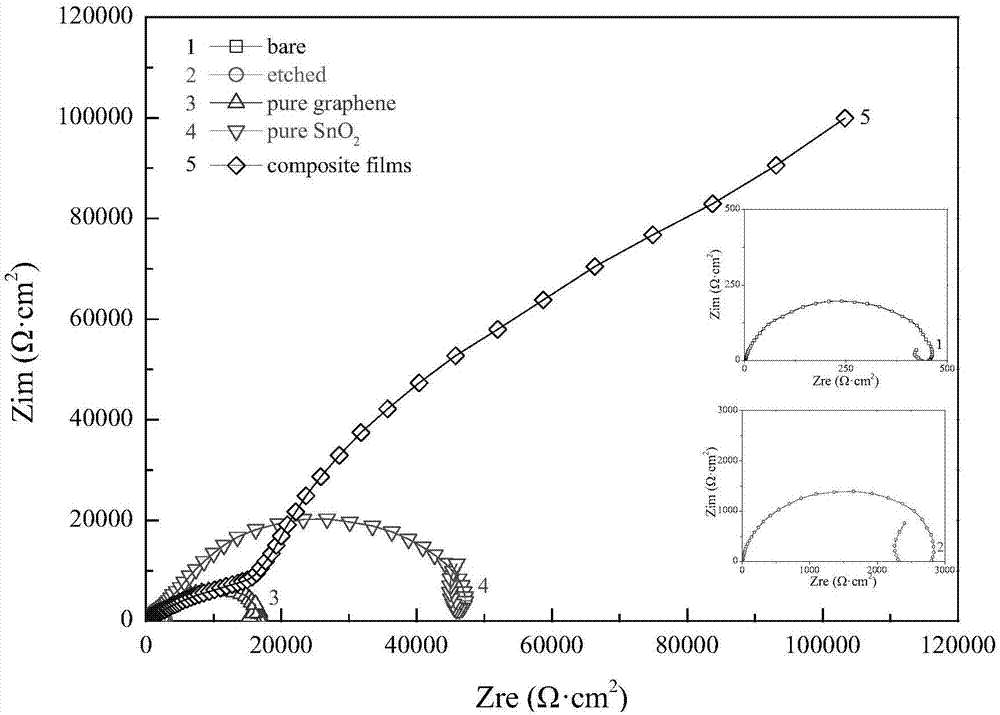

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com