Non-stick non-toxic electric cooker liner coating

A rice cooker and coating technology, which can be applied to coatings, special materials for cooking utensils, etc., can solve problems such as coating peeling, and achieve the effects of good non-stickiness, low relative density and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

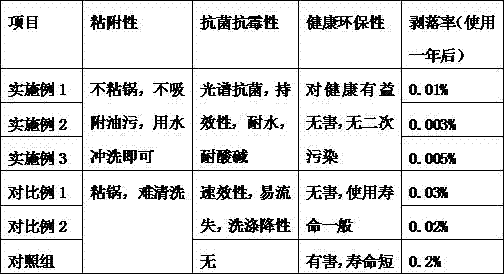

Examples

Embodiment 1

[0013] A non-stick and non-toxic coating for the liner of an electric rice cooker, which is made of the following ingredients in parts by weight: 23 parts of silicon nitride, 21 parts of titanium silicon carbide, 18 parts of iron oxide, 15 parts of titanium oxide, 12 parts of chromium oxide, 11 parts of zinc, 7 parts of silver phosphate, and 5 parts of molecular sieve zeolite, among which titanium oxide, silver phosphate, and molecular sieve zeolite are all nano-scale, and the spraying thickness is 0.1 mm. For protection, the scanning speed is 10 mm / s, and the laser is removed immediately after the coating is melted, and it can be cooled and solidified.

[0014] As a further description of the above scheme, the purity of the titanium silicon carbide is in the range of 98-99%, and its preparation method is to use titanium, silicon and graphite powder as raw materials, and put them into a silicon carbide tube furnace after grinding balls and fully mixing , under the protection o...

Embodiment 2

[0018] A non-stick and non-toxic coating for the liner of an electric rice cooker, which is made of the following components in parts by weight: 24 parts of silicon nitride, 22 parts of titanium silicon carbide, 19 parts of iron oxide, 16 parts of titanium oxide, 13 parts of chromium oxide, 12 parts of zinc, 8 parts of silver phosphate, and 6 parts of molecular sieve zeolite, among which titanium oxide, silver phosphate, and molecular sieve zeolite are all nano-scale, and the spraying thickness is 0.15 mm. The processing method adopts laser cladding processing, and the laser output power is 800W. For protection, the scanning speed is 11 mm / s, and the laser is removed immediately after the coating is melted, and it can be cooled and solidified.

[0019] As a further description of the above scheme, the purity of the titanium silicon carbide is in the range of 98-99%, and its preparation method is to use titanium, silicon and graphite powder as raw materials, and put them into a ...

Embodiment 3

[0023] A non-stick and non-toxic coating for the liner of an electric rice cooker, which is made of the following ingredients in parts by weight: 26 parts of silicon nitride, 23 parts of titanium silicon carbide, 20 parts of iron oxide, 17 parts of titanium oxide, 15 parts of chromium oxide, 13 parts of zinc, 9 parts of silver phosphate, and 7 parts of molecular sieve zeolite, among which titanium oxide, silver phosphate, and molecular sieve zeolite are all nano-scale, and the spraying thickness is 0.2 mm. The processing method adopts laser cladding processing, and the laser output power is 900W. For protection, the scanning speed is 12 mm / s, and the laser is removed immediately after the coating is melted, and it can be cooled and solidified.

[0024] As a further description of the above scheme, the purity of the titanium silicon carbide is in the range of 98-99%, and its preparation method is to use titanium, silicon and graphite powder as raw materials, and put them into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com