Method for carrying out catalytic and oxidative treatment on waste gas produced by hydrogen peroxide propylene oxidation (HPPO) device

A catalytic oxidation and exhaust gas technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problem of exhaust gas not being discharged up to standard, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

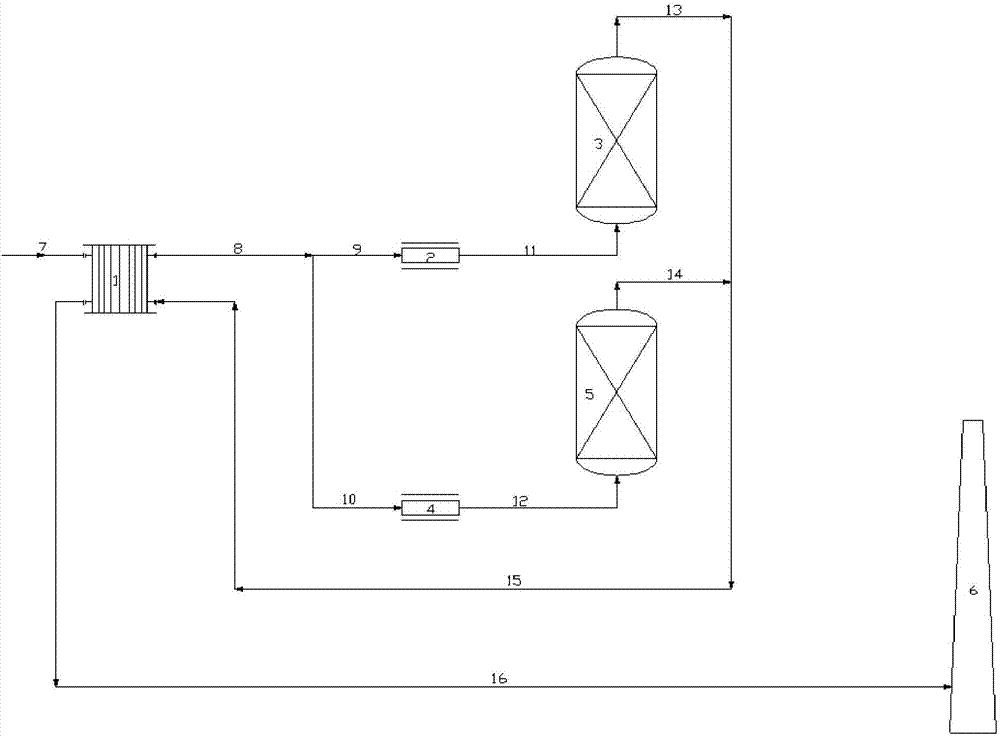

[0018] The invention relates to a method for catalytic oxidation treatment of waste gas from HPPO devices, such as figure 1 As shown, the exhaust gas of the HPPO device described in the present invention mainly contains volatile organic pollutants such as propylene, methanol, propylene oxide, and sulfide VOC. The present invention fully considers the safety redundancy of the exhaust gas treatment system, and sets 2 sets of parallel heaters- Catalytic oxidation reactor unit equipment. ① Under normal operating conditions, both sets of heater-catalytic oxidation reactor unit equipment are put into operation, and each set of unit equipment operates at 50% load; ② When the heater fails and needs to be stopped for maintenance, the unit When the equipment stops running, the operating load of another set of unit equipment is increased to 100%; ③When the catalytic oxidation reactor catalyst needs to be regenerated, this set of unit equipment stops operating, and the operating load of t...

Embodiment 2

[0025] According to the conditions and steps described in Example 1, the production scale was changed to a 100,000-ton / year HPPO industrial production unit, and the process conditions of the hydrocarbon-containing waste gas of the HPPO unit to be treated are shown in Table 1.

[0026] Adopt the method for catalytic oxidation treatment waste gas of HPPO device of the present invention, heat exchanger operating temperature is 280 ℃, heater operating temperature is 310 ℃, catalytic oxidation reactor operating temperature is 310 ℃, operating pressure is 65KPa, catalyst is 100% palladium Noble metal honeycomb catalysts. Thus, the organic pollutant VOC in hydrocarbon-containing waste gas is treated by catalytic oxidation reaction, the VOC removal rate is above 96.3%, and the concentration of non-methane total hydrocarbons in the purified waste gas after treatment is reduced to 90mg / m 3 Below, it can be discharged directly at high altitude through the exhaust pipe.

Embodiment 3

[0028] According to the conditions and steps described in Example 1, the production scale was changed to a 300,000-ton / year HPPO industrial production unit, and the process conditions of the hydrocarbon-containing waste gas of the HPPO unit to be treated are shown in Table 1.

[0029]Using the method for treating waste gas from an HPPO device by catalytic oxidation of the present invention, the operating temperature of the heat exchanger is 210°C, the operating temperature of the heater is 295°C, the operating temperature of the catalytic oxidation reactor is 295°C, the operating pressure is 57KPa, and the catalyst is 70% platinum and 30% palladium noble metal honeycomb catalyst. Thus, the organic pollutant VOC in hydrocarbon-containing waste gas is treated by catalytic oxidation reaction, the VOC removal rate is above 96.6%, and the concentration of non-methane total hydrocarbons in the purified waste gas after treatment is reduced to 87mg / m 3 Below, it can be discharged dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com