Ternary polymerization carbon nitride photocatalytic material as well as preparation method and application thereof

A ternary copolymerization of carbon nitride light and a ternary copolymerization of carbon nitride light technology, applied in the field of visible light catalysis, can solve the problems of reducing the separation efficiency of photogenerated electron-hole pairs, unable to effectively utilize solar energy, destroying semiconductor characteristics, etc. Utilization and conversion of light energy, improving photocatalytic efficiency, and reducing the effect of band gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

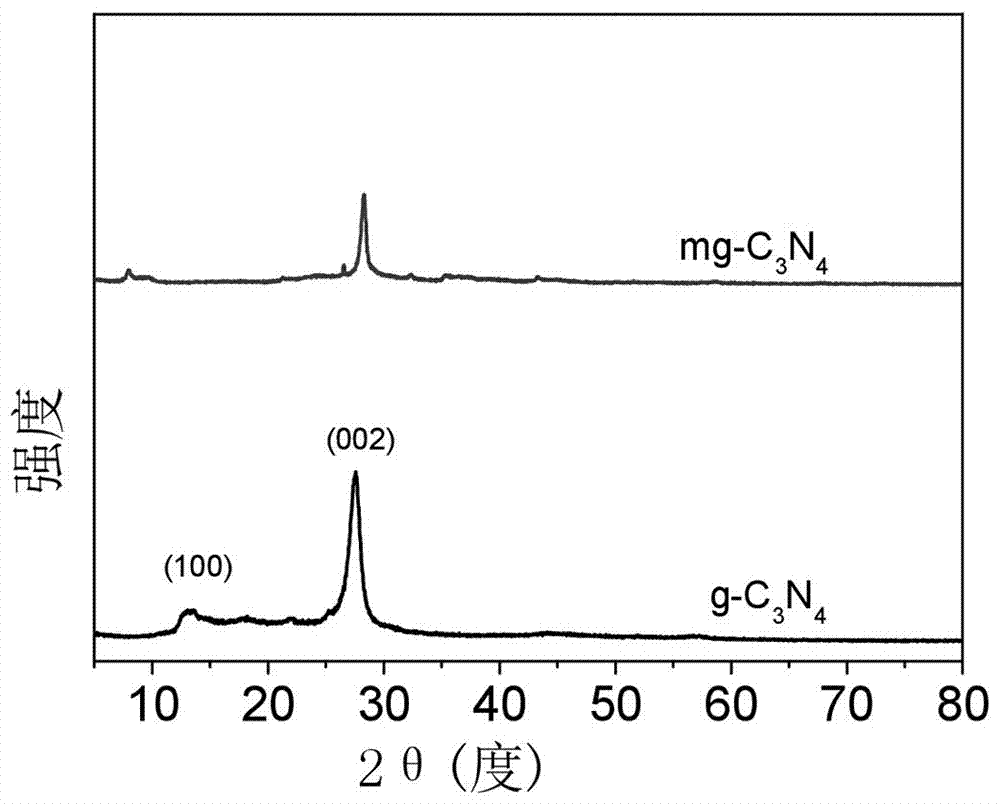

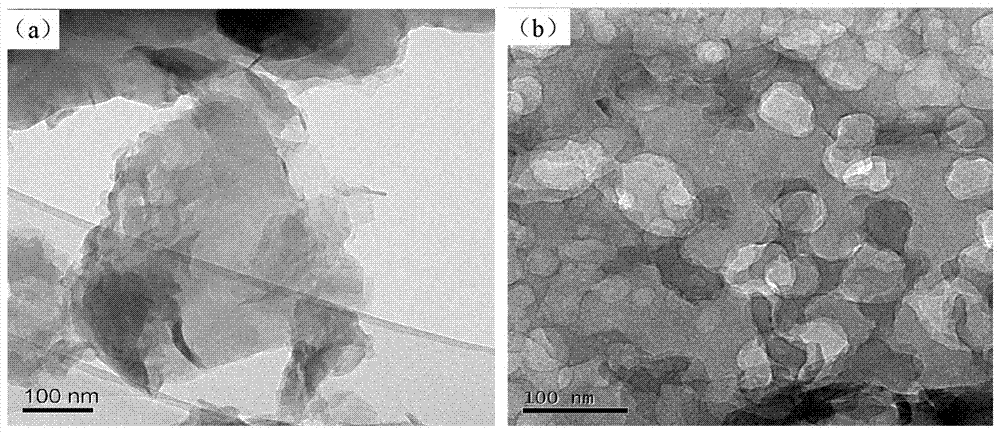

[0030] Example 1: Ternary copolymerized carbon nitride photocatalytic material (layered modified mg-C 3 N 4 ) preparation

[0031] A ternary copolymerized carbon nitride photocatalytic material of this embodiment is prepared from melamine, cyanuric acid and barbituric acid. The ternary copolymerized carbon nitride photocatalytic material has a porous structure, and the specific surface area 179m 2 / g, the pore diameter is 0.56cm 3 / g. Specifically include the following steps:

[0032] S1, get 10g melamine, 10g cyanuric acid, 1g barbituric acid (in other embodiments, 2g barbituric acid can also obtain the same technical effect), grind, dissolve in 100ml water (in other embodiments, The same technical effect can also be obtained by using ethanol), stirring at room temperature for 2 hours, and drying on an electric furnace at 80°C to obtain a precursor.

[0033] S2. Put the precursor in a muffle furnace, heat it to 550°C at a heating rate of 3°C / min, and keep it at 550°C fo...

Embodiment 2

[0034] Example 2: Ternary copolymerized carbon nitride photocatalytic material (layered modified mg-C 3 N 4 ) preparation

[0035] A ternary copolymerized carbon nitride photocatalytic material in this embodiment is prepared from melamine, cyanuric acid and barbituric acid as raw materials, and the ternary copolymerized carbon nitride photocatalytic material has a porous structure. Specifically include the following steps:

[0036] S1. Take 10g of melamine, 10g of cyanuric acid, and 2g of barbituric acid (in other embodiments, 1g of barbituric acid can also achieve the same technical effect), grind, dissolve in 100ml of water, stir at room temperature for 2h, and heat The precursor was obtained by drying in a furnace at 80°C.

[0037] S2. Put the precursor in a muffle furnace, heat it to 400°C at a heating rate of 3°C / min, and keep it at 400°C for 1 hour; continue heating at a heating rate of 3°C / min to 550°C, and keep it at 550°C After 3 hours, after natural cooling, the ...

Embodiment 3

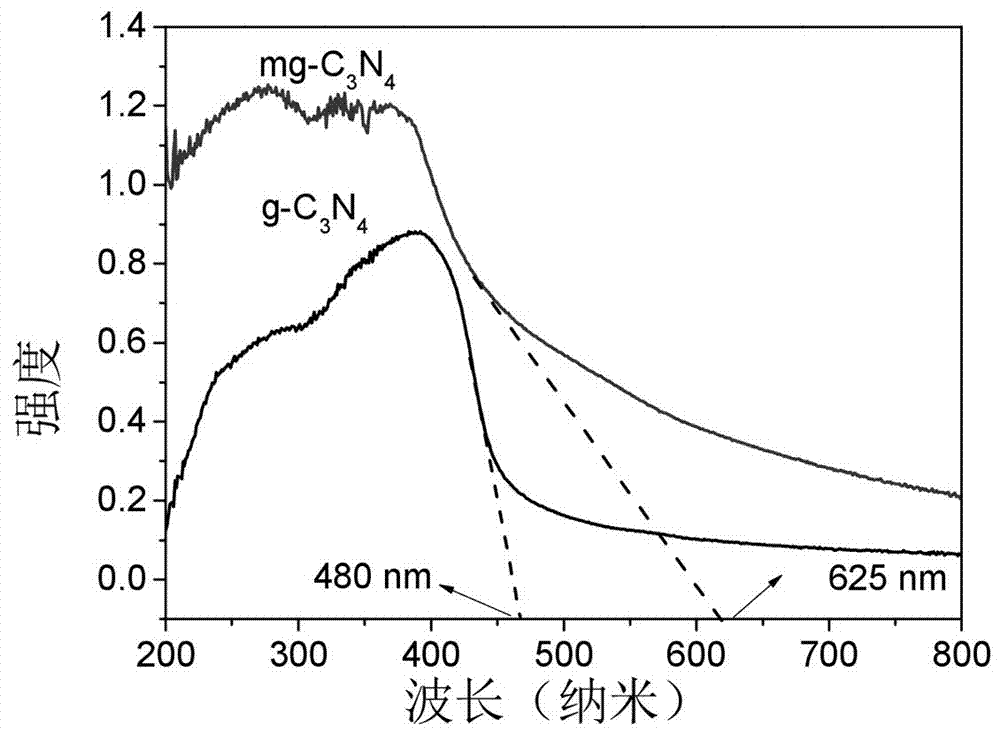

[0043] Example 3: Application of carbon nitride photocatalytic material and ternary copolymerized carbon nitride photocatalytic material to degrade Rhodamine B in water under visible light

[0044] The experiment of degrading Rhodamine B was carried out according to the carbon nitride photocatalytic material in Comparative Example 1 and the ternary copolymerized carbon nitride photocatalytic material in Example 1, wherein the concentration of Rhodamine B was 10 mg / L.

[0045] Take respectively 100 mg of the carbon nitride photocatalytic material in Comparative Example 1 and the ternary copolymerized carbon nitride photocatalytic material in Example 1, respectively place them in 100 ml of the above rhodamine B solution, stir in a dark room for 60 minutes, then place the solution in In the visible light source, take 4ml of rhodamine B solution every 10 minutes, measure the characteristic peak of rhodamine B in the solution with a UV-visible spectrophotometer, and calculate the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com