Method for fast efficiently extracting and purifying anthocyanin from lonicera caerulea

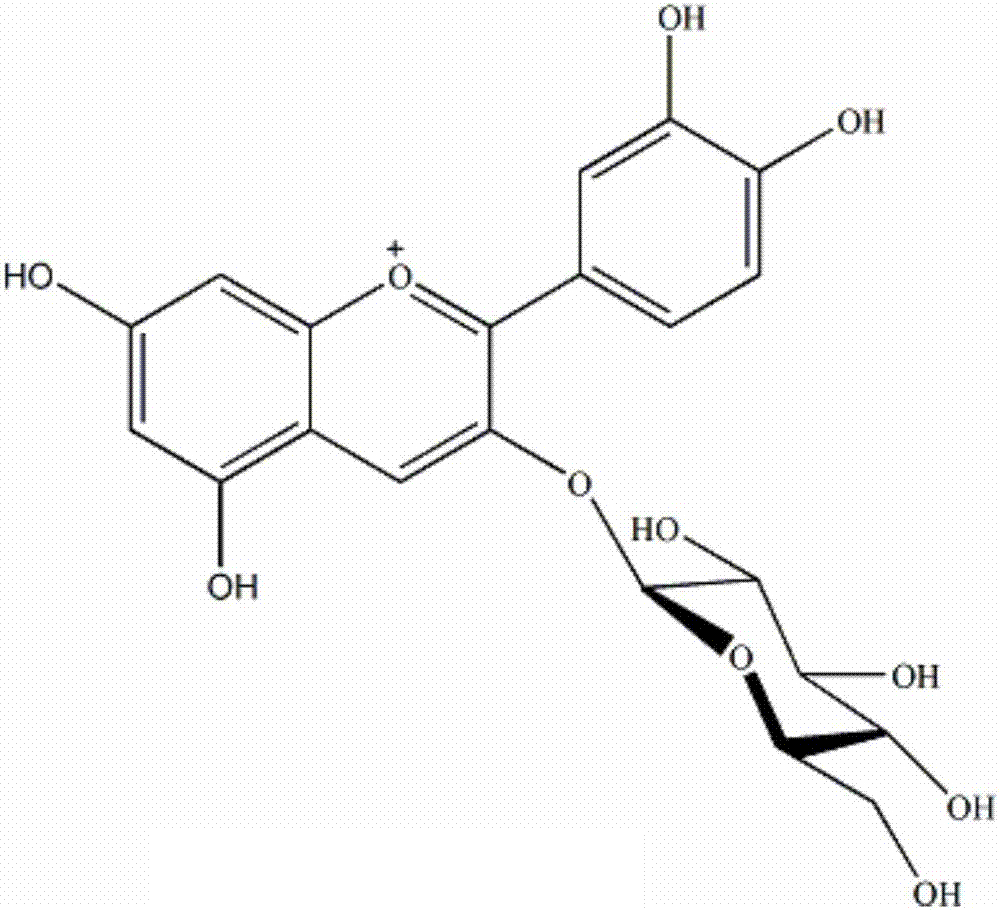

A technology of cyanidinus and anthocyanins, which is applied in the field of fast and efficient extraction and purification of cyanidin-3-O-glucoside, can solve the problems of long extraction time, low yield, large investment, etc., and achieve efficient and reasonable utilization, and obtain The effect of high efficiency and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

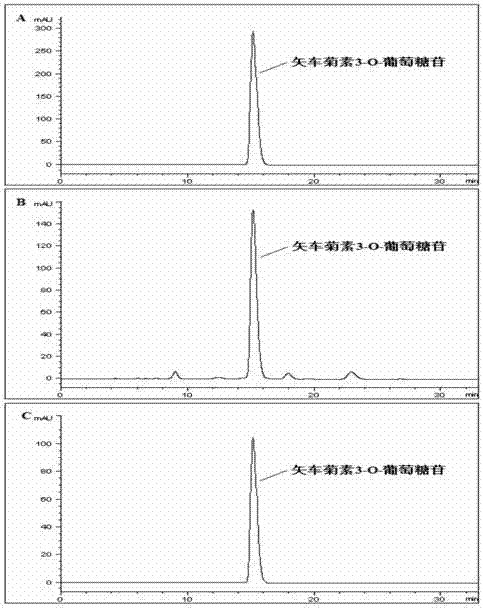

[0023] A method for quickly and efficiently extracting and purifying anthocyanins from Cydola edulis is carried out according to the following process steps:

[0024] A. High-speed homogeneous crushing of enzymatically hydrolyzed indigo fruit: 1 kg of fresh blue indigo fruit and 5 L of water were subjected to high-speed homogeneous crushing for 6 minutes, the pH of the slurry was adjusted to 4.0 with citric acid, cellulase was added to make the enzyme concentration 450U / mL, and then Enzymolysis at 40°C for 3 hours, filtering, and collecting the filtrate and filter residue;

[0025] B. Negative-pressure cavitation-enhanced extraction of indigo fruit filter residue: add 15L ethanol solution to the above-mentioned filter residue according to the mass-volume ratio for negative-pressure cavitation-enhanced extraction. The extraction temperature is 40°C, the extraction pressure is -0.05MPa, and the extraction is performed twice, each time for 50min , Combine the extract and the filt...

example 2

[0030] A method for quickly and efficiently extracting and purifying anthocyanins from Cydola edulis is carried out according to the following process steps:

[0031] A. High-speed homogeneous crushing and enzymatic hydrolysis of blue indigo fruit raw materials: 1kg of fresh blue indigo fruit and 7L of water were subjected to high-speed homogeneous crushing for 8 minutes, the pH of the slurry was adjusted to 5.0 with glacial acetic acid, and the compound enzyme of cellulase and pectinase was added to make the cellulose Enzyme concentration is 300U / mL, pectinase concentration is 200U / mL, then enzymolysis at 45°C for 4h, filter, collect filtrate and filter residue;

[0032] B. Negative-pressure cavitation-enhanced extraction of indigo fruit filter residue: add 10L ethanol solution to the above-mentioned filter residue according to the mass-volume ratio for negative-pressure cavitation-enhanced extraction. The extraction temperature is 35°C, the extraction pressure is -0.07MPa, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com