High-purity gallium electrolysis device and method

An electrolysis device and high-purity technology, applied in the field of electrolysis, can solve the problems of ineffective separation of impurities, simplified operation process, low gallium impurity content, etc., and achieve convenient centralized collection and reprocessing purification, high purity, and good removal effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

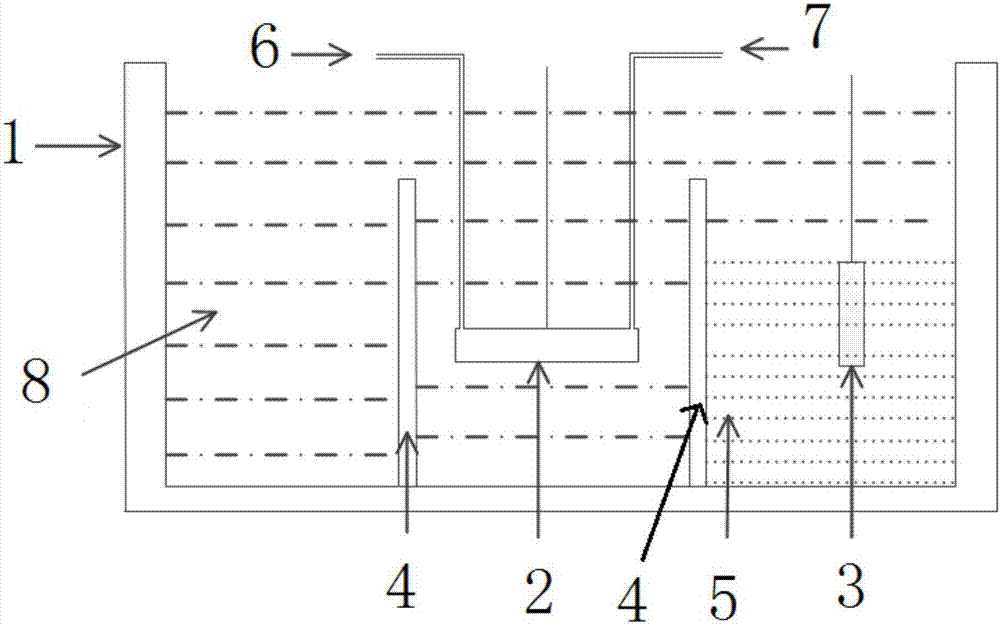

[0025] Such as figure 1 As shown, a kind of high-purity gallium electrolysis device of the present embodiment comprises an electrolytic cell 1, a cathode plate 2 and an anode plate 3, an anode area and a cathode area are separated by a separator 4 in the electrolytic cell 1, and different The raw material gallium 5 that does not pass through the separator 4, the anode plate 3 is placed in the anode area, and the cathode plate 2 is placed in the cathode area. Circulating cooling device, the electrolytic cell 1 is equipped with an electrolyte 8 that has not crossed the separator 4.

[0026] Wherein, the raw material gallium 5 is 2N gallium. The shape of the cathode plate 2 is circular. The cooling water temperature in the circulating cooling device is 10°C. The electrolyte solution 8 is an aqueous sodium hydroxide solution. The temperature of the electrolytic solution 8 was 30°C.

[0027] A method according to the electrolytic device of the above-mentioned high-purity galli...

Embodiment 2

[0033] Such as figure 1 As shown, a kind of high-purity gallium electrolysis device of the present embodiment comprises an electrolytic cell 1, a cathode plate 2 and an anode plate 3, an anode area and a cathode area are separated by a separator 4 in the electrolytic cell 1, and different The raw material gallium 5 that does not pass through the separator 4, the anode plate 3 is placed in the anode area, and the cathode plate 2 is placed in the cathode area. Circulating cooling device, the electrolytic cell 1 is equipped with an electrolyte 8 that has not crossed the separator 4.

[0034] Wherein, the raw material gallium 5 is 3N gallium. The shape of the cathode plate 2 is square. The cooling water temperature in the circulating cooling device is 25°C. Electrolyte solution 8 is sodium metagallate aqueous solution. The temperature of the electrolytic solution 8 was 30°C.

[0035] A method according to the electrolytic device of the above-mentioned high-purity gallium, com...

Embodiment 3

[0041] Such as figure 1 As shown, a kind of high-purity gallium electrolysis device of the present embodiment comprises an electrolytic cell 1, a cathode plate 2 and an anode plate 3, an anode area and a cathode area are separated by a separator 4 in the electrolytic cell 1, and different The raw material gallium 5 that does not pass through the separator 4, the anode plate 3 is placed in the anode area, and the cathode plate 2 is placed in the cathode area. Circulating cooling device, the electrolytic cell 1 is equipped with an electrolyte 8 that has not crossed the separator 4.

[0042] Wherein, the raw material gallium 5 is 4N gallium. The shape of the cathode plate 2 is circular. The cooling water temperature in the circulating cooling device is 15°C. The electrolyte solution 8 is water. The temperature of the electrolytic solution 8 was 40°C.

[0043] A method according to the electrolytic device of the above-mentioned high-purity gallium, comprising the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com