Preparation method of three dimensional rGO / In2O3 composite room temperature gas-sensitive material

A gas-sensing material, in2o3 technology, applied in the field of preparation of composite room-temperature gas-sensing materials, can solve problems such as high-tech deep processing exploration is still in its infancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

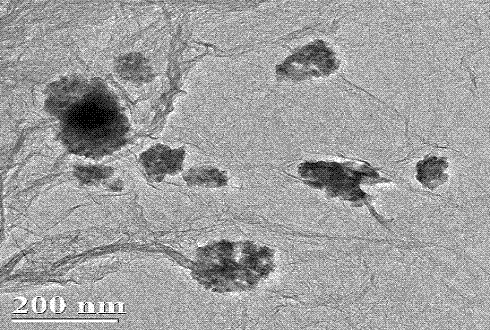

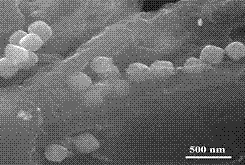

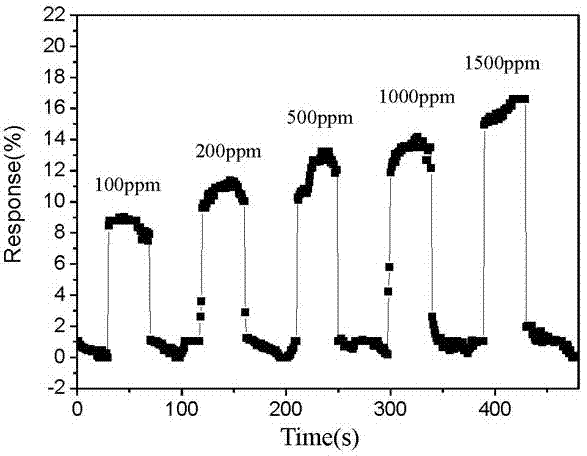

Image

Examples

Embodiment 1

[0012] (1) Weigh 240 mg of graphene oxide GO, and ultrasonically disperse it in 30 mL of deionized water to obtain a GO colloidal solution, in which the concentration of GO is 8 mg / mL;

[0013] (2) Weigh 0.027mol / l indium chloride tetrahydrate, 0.16mol / l trisodium citrate and 0.013mol / l urea, dissolve them into the GO colloidal solution obtained in step (1), stir at room temperature for 1 hour, and control The molar ratio of indium chloride tetrahydrate to trisodium citrate is 1:5.9, and the molar ratio of indium chloride tetrahydrate to urea is 1:0.48;

[0014] (3) Place the mixed solution obtained in step (2) in a reaction kettle and incubate at 140°C for 24 hours in an incubator, collect the solid product by centrifugation, wash with deionized water and absolute ethanol several times, and put it in a freeze-drying box at -50°C Dry at high temperature for 24 hours, and then perform high-temperature calcination in a tube furnace under the protection of Ar atmosphere. The calc...

Embodiment 2

[0016] (1) Weigh 150 mg of graphene oxide GO, and ultrasonically disperse it in 30 mL of deionized water to obtain a GO colloidal solution, in which the concentration of GO is 5 mg / mL;

[0017] (2) Weigh 0.02mol / l indium chloride tetrahydrate, 0.1mol / l trisodium citrate and 0.01mol / l urea, dissolve into the GO colloidal solution obtained in step (1), stir at room temperature for 1 hour, and control The molar ratio of indium chloride tetrahydrate to trisodium citrate is 1:5, and the molar ratio of indium chloride tetrahydrate to urea is 1:0.5;

[0018] (3) Place the mixed solution obtained in step (2) in a reaction kettle and incubate at 160°C for 20 hours in a constant temperature box, collect the solid product by centrifugation, wash it with deionized water and absolute ethanol several times, and put it in a freeze-drying box at -50 Dry at high temperature for 30 hours, and then perform high-temperature calcination in a tube furnace under the protection of Ar atmosphere. The ...

Embodiment 3

[0020] (1) Weigh 300 mg of graphene oxide GO, and ultrasonically disperse it in 30 mL of deionized water to obtain a GO colloidal solution, in which the concentration of GO is 10 mg / mL;

[0021] (2) Weigh 0.025mol / l indium chloride tetrahydrate, 0.15mol / l trisodium citrate and 0.015mol / l urea, dissolve into the GO colloidal solution obtained in step (1), stir at room temperature for 1 hour, and control The molar ratio of indium chloride tetrahydrate to trisodium citrate is 1:6, and the molar ratio of indium chloride tetrahydrate to urea is 1:0.6;

[0022] (3) Put the mixed solution obtained in step (2) in a reaction kettle and incubate at 150°C for 28 hours in a constant temperature box, collect the solid product by centrifugation, wash with deionized water and absolute ethanol several times, and put it in a freeze-drying box at -50°C Dry at high temperature for 38 hours, and then perform high-temperature calcination in a tube furnace under the protection of Ar atmosphere. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com