Straw decomposition agent, preparation method thereof, and method for producing solid bioorganic fertilizer in batches through decomposing straws by decomposition agent

A technology of straw decomposing agent and decomposing agent, which is applied in the field of straw decomposing agent and its preparation and batch production of solid bio-organic fertilizer through the decomposing agent decomposing straw, which can solve the problems of soil compaction, acidified nematode damage, reduction of soil organic matter content, discarding or Incineration environment and other problems to achieve the effect of eliminating pathogenic bacteria and insect eggs, promoting rapid growth, and uniform specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

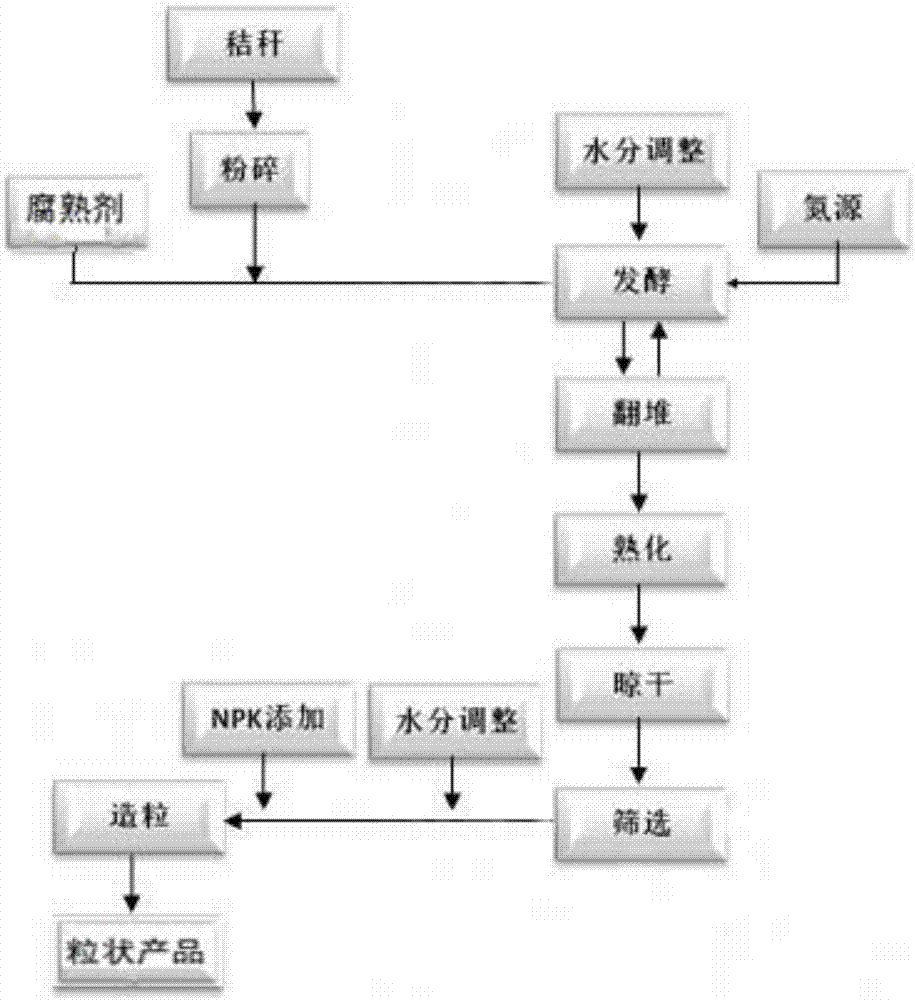

[0045] A solid bio-organic fertilizer, its preparation method is as follows:

[0046] a. After smashing the crop stalks by 3-6cm, mix them with the straw decomposing agent diluted 30 times. The addition amount of the straw decomposing agent is 4kg straw decomposing agent per ton of straw to build a pile for fermentation, and the fermentation temperature will reach 60 after 48 hours. After ~65℃, turn the pile once a day, keep the water content at 50%~70%, and the PH value of 6.5~7.5;

[0047] b. After three days of fermentation, add N, P and K fertilizers. The amount of N, P and K fertilizers added is: N fertilizer is 3.5kg per ton of straw, P fertilizer is 1.5kg per ton of straw, and K fertilizer is per ton Add 0.2kg of straw, mix evenly, and continue fermentation; after the tenth day, the temperature is 30-40℃, the water content is 30%-50%, and the pile is turned every two days. After the fifteenth day of fermentation, the temperature is the same as room temperature. The water co...

Embodiment 2

[0070] A solid bio-organic fertilizer, its preparation method is as follows:

[0071] A solid bio-organic fertilizer, its preparation method is as follows:

[0072] a. After smashing the crop stalks by 3~6cm, mix them with the straw decomposing agent diluted 30 times. The addition amount of the straw decomposing agent is 5kg of straw decomposing agent per ton of straw, building a pile for fermentation, and the fermentation temperature reaches 60 after 48 hours. After ~65℃, turn the pile once a day, keep the water content at 50%~70%, and the PH value of 6.5~7.5;

[0073] b. After three days of fermentation, add N, P, K fertilizers. The amount of N, P, K fertilizers added is: N fertilizer is 5kg per ton of straw, P fertilizer is 1kg per ton of straw, and K fertilizer is added per ton of straw. 0.2kg, mix evenly, continue fermentation; after the tenth day, the temperature is 30-40℃, the water content is 30%-50%, and the pile is turned every two days. After the fifteenth day of fermenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com