Preparation method of flame-retardation paint

A flame-retardant coating, stirring and mixing technology, applied in the direction of fire-resistant coatings, coatings, etc., can solve the problems of flame-retardant performance degradation, flame-retardant coatings containing volatile harmful ions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

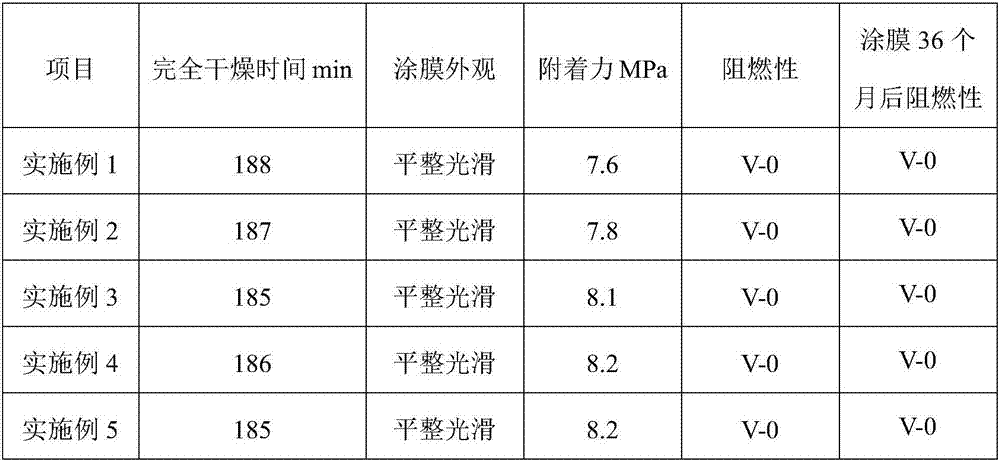

Examples

Embodiment 1

[0018] A preparation method of flame retardant coating, comprising the following steps:

[0019] (1) Stir and mix 5 parts by weight of silicate ester, 5 parts of maleic acid resin, 2 parts of propylene glycol methyl ether acetate, 1 part of sodium silicate and 3 parts of 2-phenylethyl acrylate, stir The speed is 120 rpm, and the stirring time is 20 minutes to obtain mixture 1;

[0020] (2) Add 0.5 parts of benzoyl peroxide, 1 part of pentaerythritol and 1 part of borosilicate glass powder to mixture 1, heat and keep it for 20 minutes at a heating temperature of 50°C, then add 1 part of microcrystalline cellulose, polyethylene 2 parts of diol 400, stir and mix,

[0021] The stirring speed of stirring and mixing is 150 rpm, and the stirring time is 10 minutes to obtain mixture 2;

[0022] (3) Add 3 parts of titanium dioxide, 1 part of powdered alumina and 60 parts of water to mixture 2, and grind until the particle size is less than 50 μm to obtain a flame-retardant coating. ...

Embodiment 2

[0024] A preparation method of flame retardant coating, comprising the following steps:

[0025] (1) Stir and mix 6 parts by weight of silicate ester, 7 parts of maleic acid resin, 2 parts of propylene glycol methyl ether acetate, 1 part of sodium silicate and 4 parts of 2-phenylethyl acrylate, stir The speed was 130 rev / min, and the stirring time was 22 minutes to obtain mixture 1;

[0026] (2) Add 0.6 parts of benzoyl peroxide, 1 part of pentaerythritol and 2 parts of borosilicate glass powder to mixture 1, heat and keep it for 25 minutes at a heating temperature of 56°C, then add 2 parts of microcrystalline cellulose, polyethylene 3 parts of diol 400, stirred and mixed, the stirring speed of stirring and mixing was 153 rpm, and the stirring time was 14 minutes to obtain mixture 2;

[0027] (3) Add 3 parts of titanium dioxide, 1 part of powdered alumina and 65 parts of water to mixture 2, and grind until the particle size is less than 50 μm to obtain a flame-retardant coati...

Embodiment 3

[0029] A preparation method of flame retardant coating, comprising the following steps:

[0030] (1) Stir and mix 7 parts by weight of silicate ester, 9 parts of maleic acid resin, 3 parts of propylene glycol methyl ether acetate, 2 parts of sodium silicate and 4 parts of 2-phenylethyl acrylate, stir The speed is 140 rpm, and the stirring time is 25 minutes to obtain mixture 1;

[0031] (2) Add 0.7 parts of benzoyl peroxide, 2 parts of pentaerythritol and 2 parts of borosilicate glass powder to mixture 1, heat and keep it for 24 minutes at a heating temperature of 55°C, then add 1 part of microcrystalline cellulose, polyethylene 4 parts of diol 400, stirred and mixed, the stirring speed of stirring and mixing was 155 rpm, and the stirring time was 16 minutes to obtain mixture 2;

[0032] (3) Add 4 parts of titanium dioxide, 2 parts of powdered alumina and 65 parts of water to mixture 2, and grind until the particle size is less than 50 μm to obtain a flame-retardant coating. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com