Three-layer water-containing capsules and preparation method thereof

A technology of water-containing capsules and water cores, which can be used in capsule delivery, pharmaceutical formulations, cosmetic preparations, etc. It can solve the problems of being unable to inhibit the escape of water molecules, achieve rich functions and styles, long-lasting activity, and slow down the loss of water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

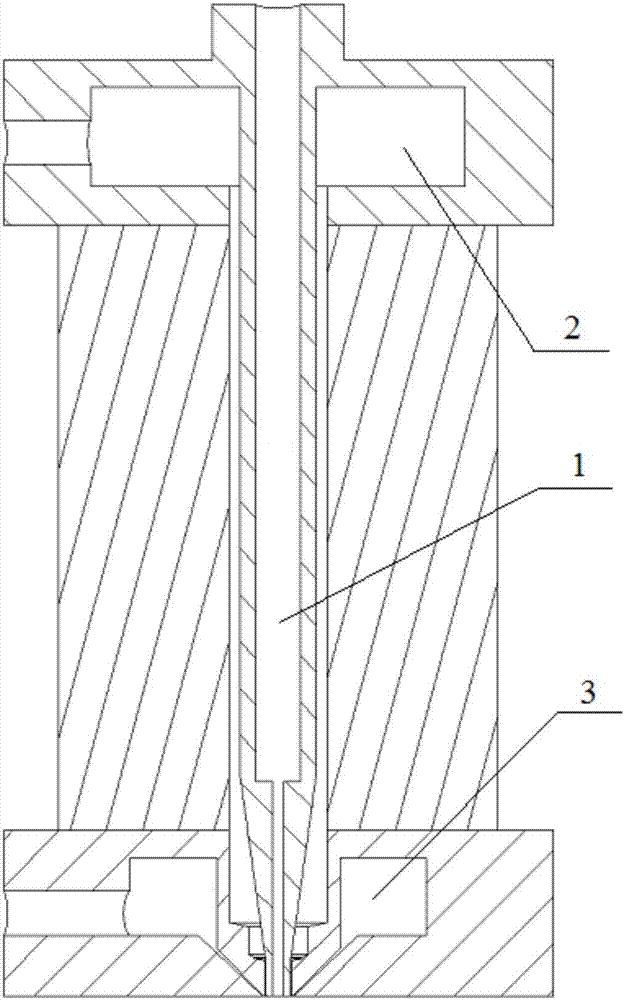

Image

Examples

Embodiment 1

[0030] The diameter of the capsule obtained in this example is about: 3.5-4.0mm, plum flavor, and its preparation method is as follows:

[0031] Preparation of aqueous core liquid layer: pure water, plum extract, propylene glycol, and sodium polyacrylate are uniformly mixed at a mass ratio of 8:1:1:0.01 to form an aqueous core material solution.

[0032] Preparation of phase-changeable grease layer: weigh palm oil and sucrose acetate isobutyrate according to a mass ratio of 5:1, mix them at 80°C and keep them warm for later use.

[0033] Preparation of natural animal and plant glue layer: Carrageenan, locust bean gum, guar gum, and starch are made into a uniformly mixed powder at a mass ratio of 1:1:0.5:0.1. After continuous stirring, the mixture is evenly dispersed and dissolved in 80℃ water, and then added The propylene glycol is mixed uniformly, and the temperature is kept at 80°C. The mass ratio of the mixed powder, propylene glycol, and water is 1:5:70.

[0034] Drop molding: Put...

Embodiment 2

[0037] The diameter of the capsule obtained in this example is about 3.5-4.0 mm, and it has a coconut flavor. The preparation method is as follows:

[0038] Preparation of aqueous core liquid layer: Dissolve and mix purified water, propylene glycol, water-soluble coconut essence, and sodium polyacrylate at a weight ratio of 9:1:1:0.01 to form an aqueous core material solution.

[0039] Preparation of phase-changeable grease layer: Weigh coconut oil and insect white wax at a mass ratio of 5:1, mix them at 80℃ and keep them warm for later use.

[0040] Preparation of natural animal and plant glue layer: Carrageenan, locust bean gum, guar gum, and starch are made into a uniformly mixed powder at a mass ratio of 1:1:0.5:0.1, and after constant stirring, evenly dispersed in 80 ℃ water, then add propylene glycol Mix well and keep warm at 80°C. The mass ratio of the mixed powder, propylene glycol, and water is 1:5:70.

[0041] Drop molding: Put the prepared water-containing core liquid layer...

Embodiment 3

[0044] The diameter of the capsule in this example is about 4.0-4.5mm, cocoa flavor, and its preparation method is as follows:

[0045] Preparation of aqueous core liquid layer: Dissolve and mix purified water, cocoa extract, and propylene glycol at a weight ratio of 9:1:1 to form an aqueous core material solution.

[0046] Preparation of phase-changeable grease layer: Weigh palm kernel oil, cocoa butter substitute and sucrose acetate isobutyrate according to a mass ratio of 1:2:1, and mix them at 80°C and keep them warm for later use.

[0047] Preparation of natural animal and plant glue layer: Carrageenan, locust bean gum, guar gum and starch are made into a uniformly mixed powder at a mass ratio of 1:1:0.5:0.1, and after constant stirring, evenly dispersed in 80 ℃ water, and then add propylene glycol Mix well and keep warm at 80°C, where the mass ratio of the mixed powder, propylene glycol, and water is 1:4.5:70.

[0048] Drop molding: Put the prepared water-containing core liquid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com