Mixed matrix membrane with heat resistance and solvent resistance and preparation method and application thereof

A mixed-matrix membrane and mixed-matrix technology, applied in the field of membrane separation technology and new materials, can solve the problems of poor solvent resistance and heat resistance of membranes, reduced permeation flux, and reduced porosity, and achieve excellent solvent resistance and Effects of heat resistance, permeation separation performance improvement, and membrane separation performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

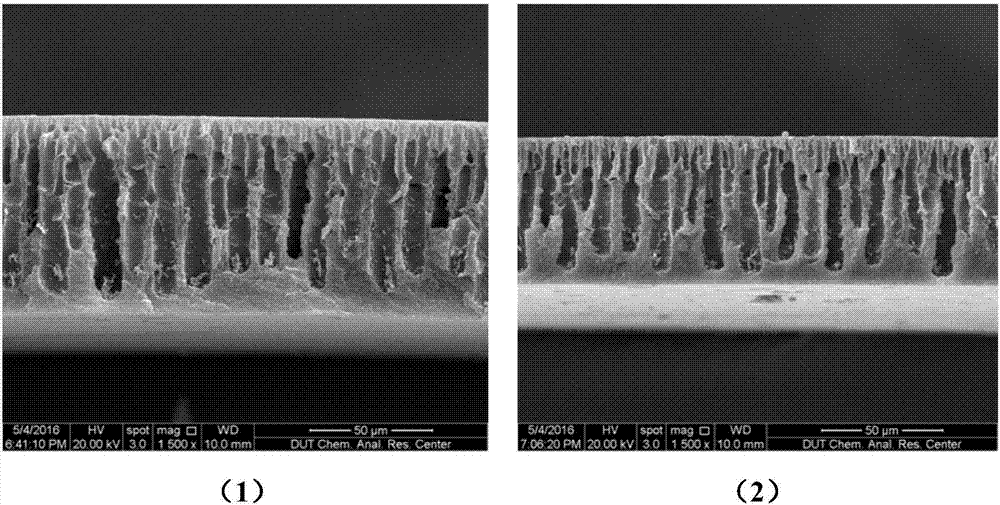

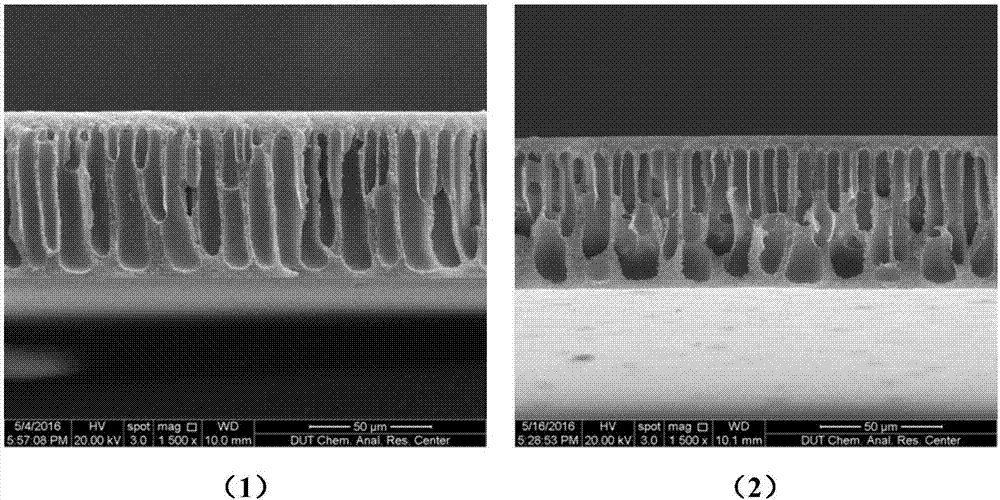

[0028]PAA, GO, TIPT, HAc, and DMF were configured as film-forming liquids, and a liquid film with a thickness of 200 μm was prepared, wherein the mass fraction of PAA was 12wt.%, the mass fraction of GO was 0.003wt.%, and the mass fraction of TIPT The fraction is 0.2wt.%, and the mass fraction of HAc is 0.4wt.%. After the liquid film is placed in the air for 40s, it is immersed in an acidic gel bath with a pH value of 5 at 80°C for 10min; It was soaked in deionized water for 24 hours, and then vacuum-dried at 60° C. for 12 hours to obtain a mixed matrix original film. The mixed matrix original film was placed in a thermal oxidation crosslinking device, the temperature was raised from room temperature, and thermal oxidation crosslinking was carried out in the air; the heating rate was 3°C / min, the air flow rate was 1L / min, and the thermal oxidation crosslinking temperature The temperature is 400°C, and the thermal oxidation crosslinking time is 2h. After reaching the final tem...

Embodiment 2-10

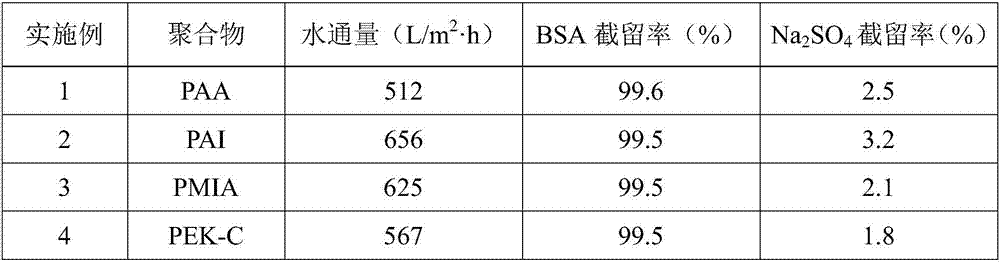

[0034] Selected polymer in the following table 3, select the most polar DMSO as the solvent resistance test solvent to repeat the method of embodiment 1, carry out the solvent resistance test, the test results are listed in the following table 3; according to the following table 1 The method of Example 1 was repeated with the polymers specified in Table 4, and the test results are listed in Table 1 and Table 4.

[0035] Table 1

[0036]

[0037]

[0038] Table 2

[0039]

[0040] table 3

[0041]

[0042]

[0043] Table 4

[0044]

Embodiment 11-16

[0046] Selected metal alkoxide in following table 5, select the method for repeating embodiment 1 of DMSO with the strongest polarity, carry out solvent resistance test, listed test result in following table 5; Press in following table 4 and table 6 The method of Example 1 was repeated for specified metal alkoxides, and the test results are listed in Table 4 and Table 6.

[0047] Table 4

[0048]

[0049]

[0050] table 5

[0051] Example

Membrane mass loss after immersion in DMSO for one week

Membrane morphology after soaking in DMSO for one week

11

TEOS

no loss

no change

12

TIPS

no loss

no change

13

TET

no loss

no change

14

TIPT

no loss

no change

15

TBT

no loss

no change

16

TIOT

no loss

no change

[0052] Table 6

[0053]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com