Preparation method for B-doped MoSe2 two-dimensional nanosheet with nano-array structure

A two-dimensional nano, nano array technology, applied in nanotechnology, chemical instruments and methods, electrodes, etc., can solve problems such as poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

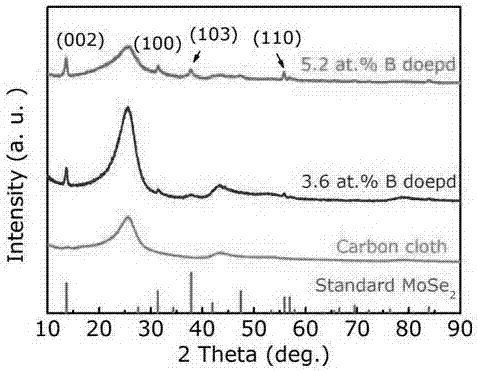

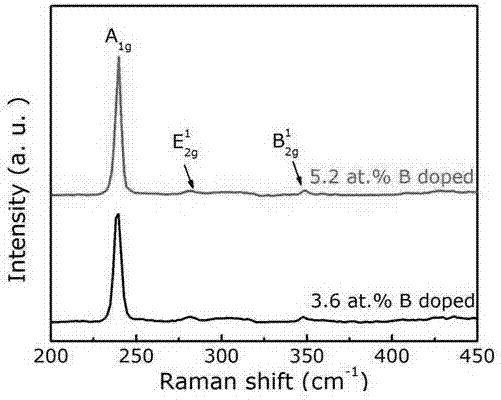

[0028] A B-doped MoSe with nano-array structure 2 The preparation method of two-dimensional nanosheets, the specific preparation process is as follows: the carbon cloth is cut into a size of 1 cm×2 cm, soaked in anhydrous acetone for 10 min, and then taken out, cleaned with deionized water, and dried with a hair dryer. Then put it in absolute ethanol for 15 min, take it out for cleaning, dry it in alcohol and set aside.

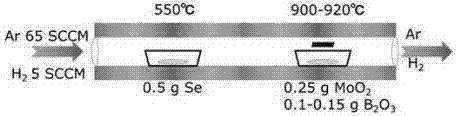

[0029] 0.25 g MoO 2 powder and 0.1 g B 2 o 3 The powder was placed in the same porcelain boat, placed in the high temperature zone of the dual temperature zone tube furnace, and then 0.5 g Se powder was placed in another porcelain boat, placed in the low temperature zone of the tube furnace. Then, along the direction of the low-temperature zone-high-temperature zone, a carrier gas of 65 SCCM argon and 5 SCCM hydrogen mixed gas is passed at the same time. After the carrier gas was passed for 15 min, the temperature of the two temperature zones was raised s...

Embodiment 2

[0033] A B-doped MoSe with nano-array structure 2 The preparation method of two-dimensional nanosheets, the specific preparation process is as follows: cut the carbon cloth into a size of 1 cm×2 cm, soak it in anhydrous acetone for 5 min, take it out, wash it with deionized water, and dry it with a hair dryer. Then put it into absolute ethanol for 10 minutes of ultrasonication, take it out for cleaning, dry it in alcohol and set aside.

[0034] 0.25 g MoO 2 powder and 0.15 g B 2 o 3 The powder was placed in the same porcelain boat in the high temperature zone of the dual temperature zone tube furnace, and 0.5 g of Se powder was placed in another porcelain boat in the low temperature zone of the tube furnace. Then, along the direction of the low-temperature zone-high-temperature zone, a carrier gas of 78 SCCM of argon and 6 SCCM of hydrogen gas mixture is passed at the same time. After the carrier gas circulated for 15 min, the temperature of the two temperature zones was r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com