Preparation method of b-doped mose2 two-dimensional nanosheets with nanoarray structure

A two-dimensional nano, nano-array technology, applied in nanotechnology, chemical instruments and methods, molybdenum compounds, etc., can solve problems such as poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A B-doped MoSe with nano-array structure 2 The preparation method of two-dimensional nanosheets, the specific preparation process is as follows: the carbon cloth is cut into a size of 1 cm×2 cm, soaked in anhydrous acetone for 10 min, and then taken out, cleaned with deionized water, and dried with a hair dryer. Then put it in absolute ethanol for 15 min, take it out for cleaning, dry it in alcohol and set aside.

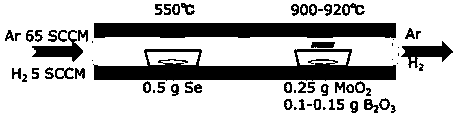

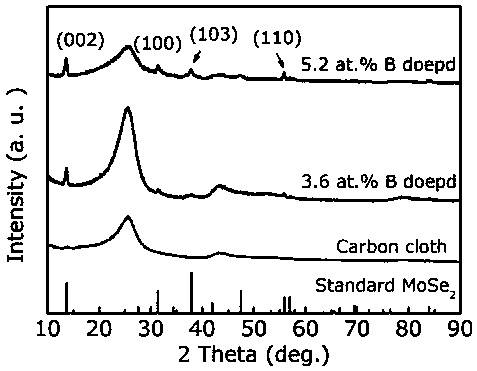

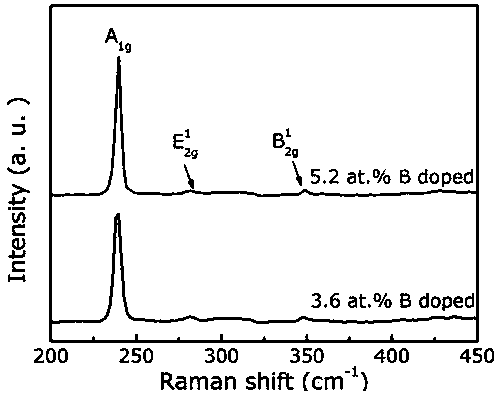

[0029] 0.25 g MoO 2 powder and 0.1 g B 2 o 3 The powder was placed in the same porcelain boat, placed in the high temperature zone of the dual temperature zone tube furnace, and then 0.5 g Se powder was placed in another porcelain boat, placed in the low temperature zone of the tube furnace. Then, along the direction of the low-temperature zone-high-temperature zone, a carrier gas of 65 SCCM argon and 5 SCCM hydrogen mixed gas is passed at the same time. After the carrier gas was passed for 15 min, the temperature of the two temperature zones was raised s...

Embodiment 2

[0033] A B-doped MoSe with nano-array structure 2 The preparation method of two-dimensional nanosheets, the specific preparation process is as follows: cut the carbon cloth into a size of 1 cm×2 cm, soak it in anhydrous acetone for 5 min, take it out, wash it with deionized water, and dry it with a hair dryer. Then put it into absolute ethanol for 10 minutes of ultrasonication, take it out for cleaning, dry it in alcohol and set aside.

[0034] 0.25 g MoO 2 powder and 0.15 g B 2 o 3 The powder was placed in the same porcelain boat in the high temperature zone of the dual temperature zone tube furnace, and 0.5 g of Se powder was placed in another porcelain boat in the low temperature zone of the tube furnace. Then, along the direction of the low-temperature zone-high-temperature zone, a carrier gas of 78 SCCM of argon and 6 SCCM of hydrogen gas mixture is passed at the same time. After the carrier gas circulated for 15 min, the temperature of the two temperature zones was r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com