Nano-composite type insulated flame-retardant cable material

A technology of flame-retardant cables and nanomaterials, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve problems such as reducing the service life of cables, and achieve the effects of improving processing performance, avoiding polymerization, and increasing average breakdown strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

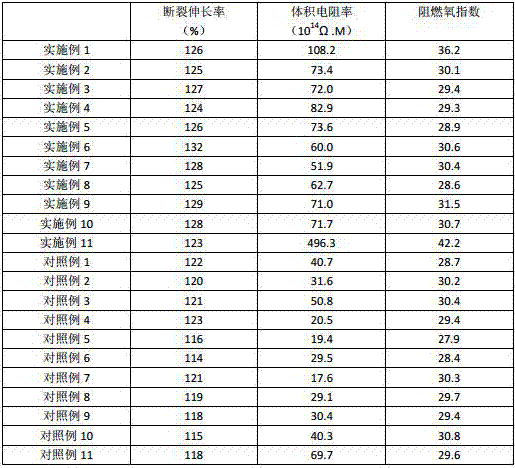

Examples

Embodiment 1

[0018] A nanocomposite insulating cable material, the preparation method of which comprises the following steps:

[0019] Weigh 100 parts of polyene modified LDHS / MCM-22 nanomaterials, 40 parts of modified tert-butylphenol phenamine resin, 36 parts of phenolic resin, 10 parts of hydroxyapatite, 8 parts of N-ethyl-N-benzene Zinc dithiocarbamate, 20 parts ethylene propylene rubber, 7 parts dicyclohexyl phthalate. The above components are mixed separately, then hot-melted, extruded through a die with a through hole to prepare a cable material that meets the requirements, then cooled by water, and dried to obtain nano-insulated flame-retardant materials. Material.

[0020] The preparation method of described polyene modified LDHS / MCM-22 nanometer material is as follows:

[0021] Step 1. Put 500g of MCM-22 raw powder into a quartz tube, and bake it at a rate of 3°C / min from 25°C to 540°C under a nitrogen flow, and then place it in a muffle furnace at 540°C for another 3 hours to ...

Embodiment 2

[0030] Weigh 80 parts of polyene modified LDHS / MCM-22 nanomaterials, 50 parts of modified tert-butylphenol phenamine resin, 36 parts of phenolic resin, 10 parts of hydroxyapatite, 8 parts of N-ethyl-N-benzene Zinc dithiocarbamate, 20 parts ethylene propylene rubber, 7 parts dicyclohexyl phthalate. The above components are mixed separately, then hot-melted, extruded through a die with a through hole to prepare a cable material that meets the requirements, then cooled by water, and dried to obtain nano-insulated flame-retardant materials. Material. All the other preparations are the same as in Example 1.

Embodiment 3

[0032] Weigh 60 parts of polyene modified LDHS / MCM-22 nanomaterials, 60 parts of modified tert-butylphenol phenamine resin, 36 parts of phenolic resin, 10 parts of hydroxyapatite, 8 parts of N-ethyl-N-benzene Zinc dithiocarbamate, 20 parts ethylene propylene rubber, 7 parts dicyclohexyl phthalate. The above components are mixed separately, then hot-melted, extruded through a die with a through hole to prepare a cable material that meets the requirements, then cooled by water, and dried to obtain nano-insulated flame-retardant materials. Material.

[0033] All the other preparations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com