Method for using proton irradiation to prepare ultrafast response GaN photoconductive switch

A technology of photoconductive switching and proton irradiation, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of low on-state current of devices, decrease in film quality, and decrease in mobility, etc., and achieve broad application prospects and great scientific value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

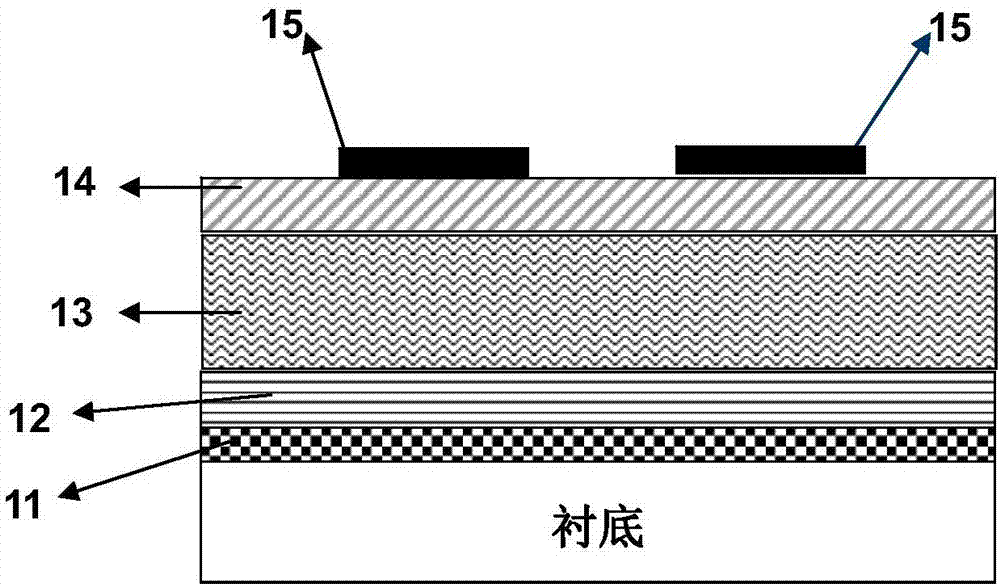

[0043] The GaN photoconductive switch of the present invention comprises, from bottom to top, a sapphire substrate, an AlN nucleation layer 11 , a GaN high temperature buffer layer 12 , an i-GaN layer 13 and an n-GaN layer 14 . The thickness of the AlN nucleation layer 11 is 100nm; the thickness of the GaN high-temperature buffer layer 12 is 1.0μm; the thickness of the i-GaN layer 13 is 100nm, and the electron concentration is 8×10 16 / cm 3 ; The n-GaN layer 14 has a thickness of 100nm and an electron concentration of 1×10 20 / cm 3 . The surface of the n-GaN layer 14 is Ni / Cr / Au parallel ohmic contact metal electrodes 15 with an electrode width of 5mm and an electrode spacing of 0.5mm.

Embodiment 2

[0045] The GaN photoconductive switch of the present invention comprises, from bottom to top, a sapphire substrate, an AlN nucleation layer 11 , a GaN high temperature buffer layer 12 ; an i-GaN layer 13 and an n-GaN layer 14 . Among them, the thickness of the AlN nucleation layer 11 is 80nm; the thickness of the GaN high temperature buffer layer 12 is 1.5μm; the thickness of the i-GaN layer 13 is 400nm, and the electron concentration is 1×10 16 / cm 3 ; The n-GaN layer 14 has a thickness of 150nm and an electron concentration of 6×10 21 / cm 3 . The surface of the n-GaN layer 14 is Ni / Cr / Au parallel ohmic contact metal electrodes 15, the electrode width is 3mm, and the electrode spacing is 3mm.

Embodiment 3

[0047] The GaN photoconductive switch of the present invention comprises, from bottom to top, a sapphire substrate, an AlN nucleation layer 11 , a GaN high temperature buffer layer 12 , an i-GaN layer 13 and an n-GaN layer 14 . Among them, the thickness of the AlN nucleation layer 11 is 180nm; the thickness of the GaN high-temperature buffer layer 12 is 1.2μm; the thickness of the i-GaN layer 13 is 200nm, and the electron concentration is 2×10 17 / cm 3 ; The n-GaN layer 14 has a thickness of 50nm and an electron concentration of 6×10 21 / cm 3 . The surface of the n-GaN layer 14 is Ni / Cr / Au parallel ohmic contact metal electrodes 15 with an electrode width of 0.5mm and an electrode spacing of 5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com