High-quality moulding sand

A kind of molding sand and high-quality technology, applied in the field of foundry sand, can solve the problems of poor surface finish, high mud content, high water content, poor air permeability of molding sand, etc., and achieve the effect of improving molding sand performance, molding sand performance and surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

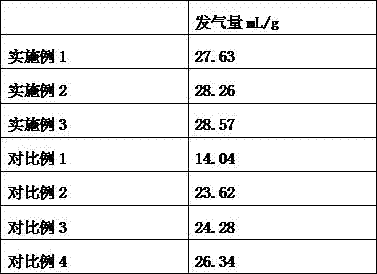

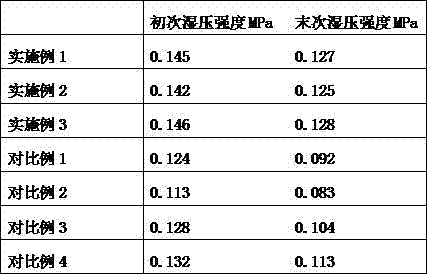

Examples

Embodiment 1

[0016] A high-quality molding sand, which is made by uniformly mixing raw sand, molding sand binder and auxiliary additives in a mass ratio of 100:5:0.5;

[0017] The raw sand is quartz sand; the molding sand binder is bentonite; the auxiliary additive is modified pine nut shell powder;

[0018] The modified pine nut shell powder is made of the following components in parts by weight: pine nut shell 70, modified diatomite 5;

[0019] The modified diatomite is modified by urea and halloysite powder under alkaline conditions, wherein the mass ratio of urea, halloysite powder and diatomite is 1:3:20.

[0020] Further, the particle size of the quartz sand is 75 mesh.

[0021] Further, the bentonite is sodium bentonite, and the particle size of sodium bentonite is 500 mesh.

[0022] Further, the preparation method of the modified diatomite is as follows: uniformly mix halloysite powder and sodium hydroxide solution with a mass fraction of 5% in the ratio of 2g:100ml, heat to 80°C...

Embodiment 2

[0026] A kind of high-quality molding sand, which is made by uniformly mixing raw sand, molding sand binder and auxiliary additives in a mass ratio of 105:8:0.8;

[0027] The raw sand is quartz sand; the molding sand binder is bentonite; the auxiliary additive is modified pine nut shell powder;

[0028] The modified pine nut shell powder is made of the following components in parts by weight: pine nut shell 780, modified diatomite 8;

[0029] The modified diatomite is modified by urea and halloysite powder under alkaline conditions, wherein the mass ratio of urea, halloysite powder and diatomite is 1:3:20.

[0030] Further, the particle size of the quartz sand is 75 mesh.

[0031] Further, the bentonite is sodium bentonite, and the particle size of sodium bentonite is 500 mesh.

[0032] Further, the preparation method of the modified diatomite is as follows: uniformly mix halloysite powder and sodium hydroxide solution with a mass fraction of 5% in the ratio of 2g:100ml, hea...

Embodiment 3

[0036] A high-quality molding sand, which is made by uniformly mixing raw sand, molding sand binder and auxiliary additives in a mass ratio of 102:6:0.6;

[0037] The raw sand is quartz sand; the molding sand binder is bentonite; the auxiliary additive is modified pine nut shell powder;

[0038] The modified pine nut shell powder is made of the following components in parts by weight: pine nut shell 75, modified diatomite 6;

[0039] The modified diatomite is modified by urea and halloysite powder under alkaline conditions, wherein the mass ratio of urea, halloysite powder and diatomite is 1:3:20.

[0040] Further, the particle size of the quartz sand is 75 mesh.

[0041] Further, the bentonite is sodium bentonite, and the particle size of sodium bentonite is 500 mesh.

[0042]Further, the preparation method of the modified diatomite is as follows: uniformly mix halloysite powder and sodium hydroxide solution with a mass fraction of 5% in the ratio of 2g:100ml, heat to 80°C,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com