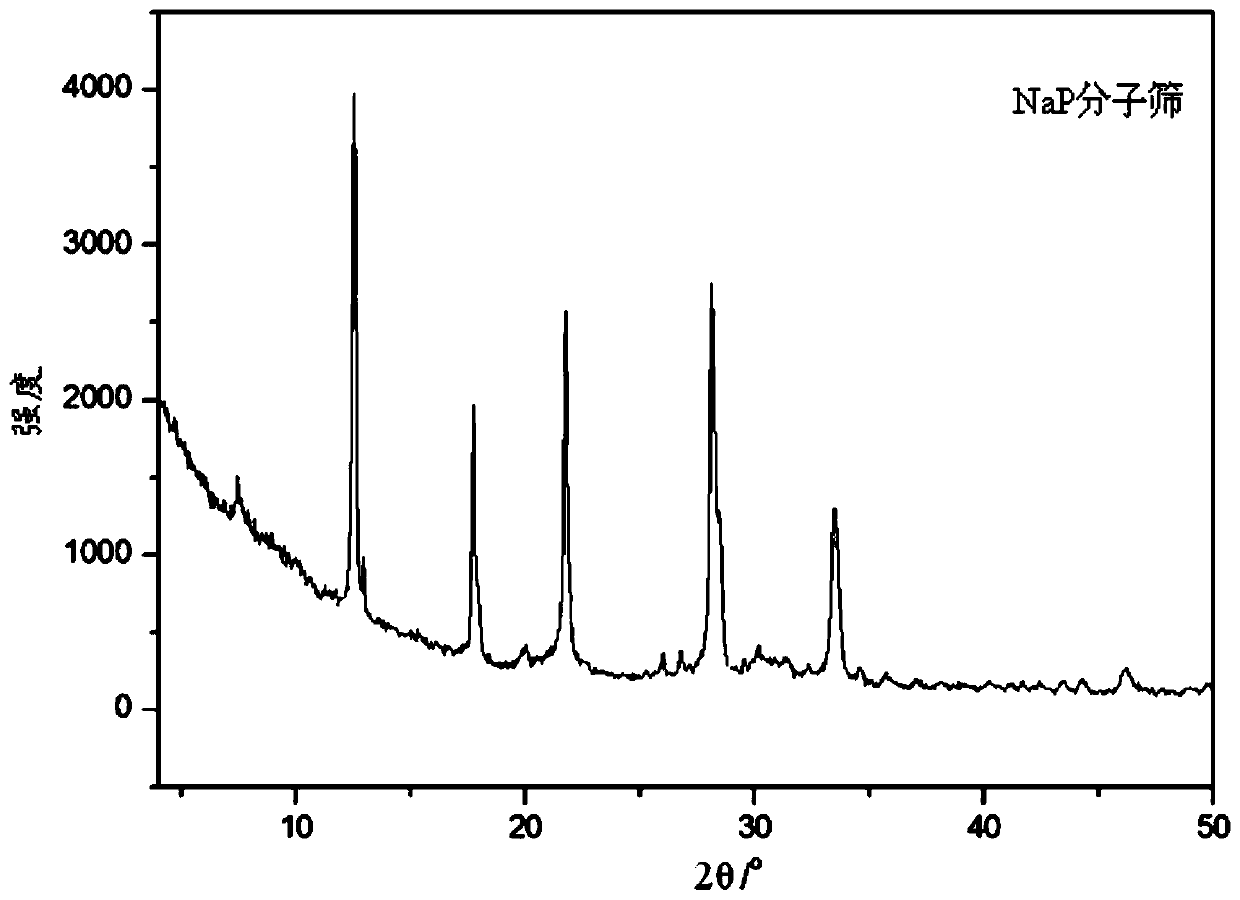

Method for preparing nap molecular sieve and nap molecular sieve with white mud as raw material

A technology of molecular sieve and lime mud, applied in the field of molecular sieve, can solve the problems of declining market competitiveness and high cost, and achieve the effect of strong market competitiveness, low production cost and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043](1) Preparation of structure directing agent

[0044] First, mix sodium metaaluminate with deionized water and stir to dissolve it completely, then add sodium silicate solution to it under stirring conditions to make the Na in the system 2 O, Al 2 o 3 , SiO 2 and H 2 The molar ratio of O is 1:0.06:0.9:18, stirring at a constant temperature of 40°C for 18 hours to obtain a structure-directing agent, which is then sealed and kept at a constant temperature for later use;

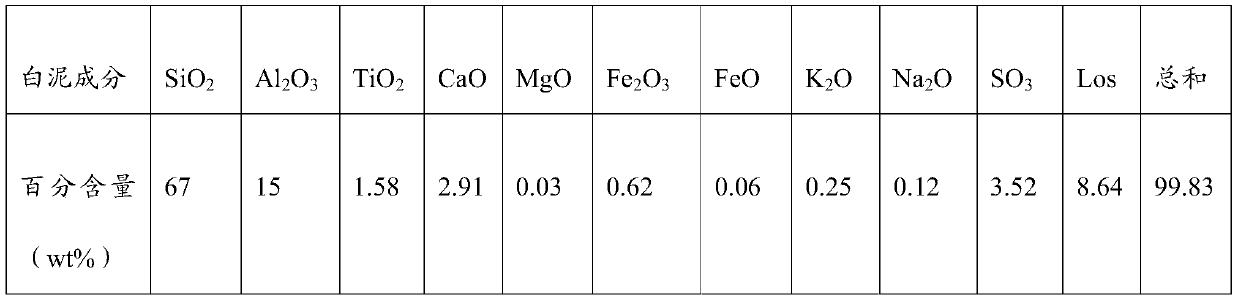

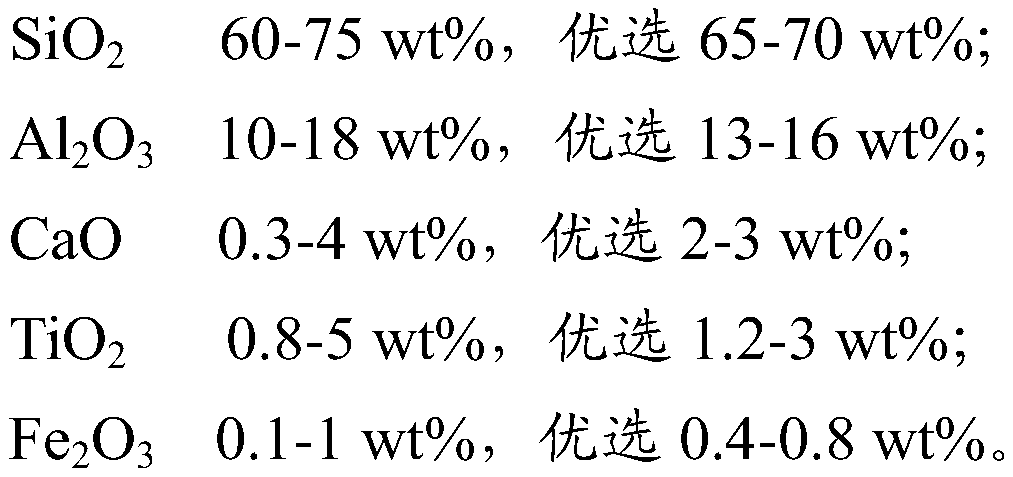

[0045] (2) Preparation of silicon source and aluminum source

[0046] Add 240ml of 4mol / L sodium hydroxide solution to 40g white mud for leaching (the mass ratio of sodium hydroxide and white mud is 1:0.96), to leach soluble silicon and aluminum, then filter, and collect the filtrate for subsequent use ; Among them, the alkali leaching temperature is 70°C, and the alkali leaching time is 4h; SiO 2 、Al 2 o 3 The extraction rates were 56.99% and 23.06% respectively;

[0047] (3) Preparation of sili...

Embodiment 2

[0055] (1) Preparation of structure directing agent

[0056] First, mix sodium metaaluminate with deionized water and stir to dissolve it completely, then add sodium silicate solution to it under stirring conditions to make the Na in the system 2 O, Al 2 o 3 , SiO 2 and H 2 The molar ratio of O is 1:0.05:0.7:20, stirring at a constant temperature of 25°C for 24 hours to obtain a structure-directing agent, which is then sealed and kept at a constant temperature for later use;

[0057] (2) Preparation of silicon source and aluminum source

[0058] Add 240ml of 3.5mol / L sodium hydroxide solution to 40g white mud and leach it (the mass ratio of sodium hydroxide and white mud is 1:0.84), to leach soluble silicon and aluminum, then filter and collect the filtrate Standby; among them, the alkali leaching temperature is 60°C, and the alkali leaching time is 4.5h; SiO 2 、Al 2 o 3 The extraction rates were 56.56% and 20.25% respectively;

[0059] (3) Preparation of silica-alumi...

Embodiment 3

[0067] (1) Preparation of structure directing agent

[0068] First, mix sodium metaaluminate with deionized water and stir to dissolve it completely, then add sodium silicate solution to it under stirring conditions to make the Na in the system 2 O, Al 2 o 3 , SiO 2 and H 2 The molar ratio of O is 1:0.07:1.1:16, stirring at a constant temperature of 50°C for 12 hours to obtain a structure-directing agent, which is then sealed and kept at a constant temperature for later use;

[0069] (2) Preparation of silicon source and aluminum source

[0070] Add 240ml of 5mol / L sodium hydroxide solution to 40g white mud for leaching (the mass ratio of sodium hydroxide and white mud is 1:1.2), to leach soluble silicon and aluminum, then filter, and collect the filtrate for subsequent use ; Among them, the alkali leaching temperature is 80 ℃, and the alkali leaching time is 3.5h; SiO 2 、Al 2 o 3 The extraction rates were 55.81% and 23.59% respectively;

[0071] (3) Preparation of si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com