Secondary amide di-quaternary ammonium salt type hydroxypropyl sodium sulfonate asphalt emulsifier and preparation method thereof

A technology of sodium hydroxypropyl sulfonate and asphalt emulsifier, which is applied in the preparation of sulfonates, the preparation of carboxylic acid amides, chemical instruments and methods, etc. Stabilizing, enhancing charge strength, improving the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] For above asphalt emulsifier, the present invention also provides its preparation method, comprises the following steps:

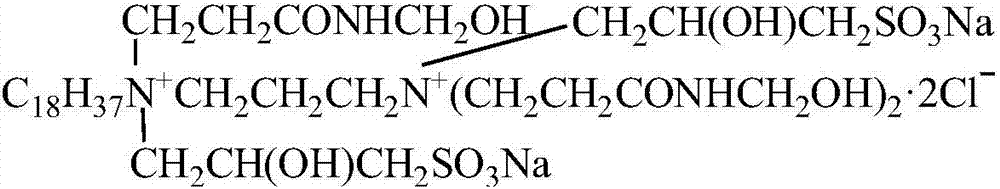

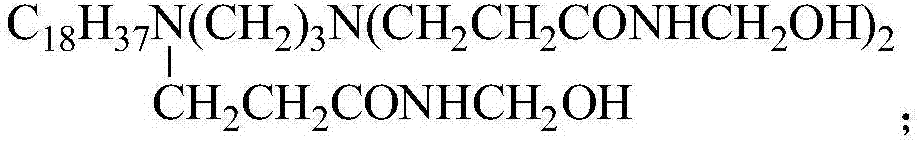

[0037](1) N-hydrogenated tallow-1,3-propylenediamine, alcohol solvent and N-methylolacrylamide are mixed and reacted to obtain reaction intermediate I, and intermediate I is

[0038]

[0039] (2) Add 3-chloro-2-hydroxypropyl sodium sulfonate into the reaction intermediate I and react to obtain secondary amide bisquaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier.

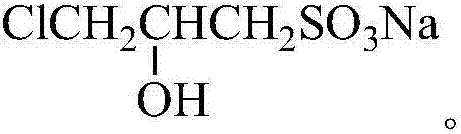

[0040] In the preferred technical scheme of the present invention, the preparation method of described 3-chloro-2-hydroxypropyl sodium sulfonate comprises the following steps:

[0041] Dissolve sodium bisulfite in water, heat to a certain temperature, then gradually add epichlorohydrin, mix and react to obtain reaction intermediate II, intermediate II is 3-chloro-2-hydroxypropyl sodium sulfonate

[0042]

[0043] Preferably, the reaction temperature is ...

Embodiment 1

[0061] (1) Preparation of secondary amide diquaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier:

[0062] 1) Add 326.0g of N-hydrogenated tallow-1,3-propylenediamine and 330g of isopropanol into the reactor, heat and stir to dissolve. Then, 321.2 g of N-methylolacrylamide (96% content) was added gradually, and the reaction was stirred at 70° C. for 3 h.

[0063] The above synthetic intermediate product was separated and purified by recrystallization and then detected by FTIR. The results are as follows: 3315cm -1 It is the stretching vibration absorption peak of O-H, 3070cm -1 It is the stretching vibration absorption peak of N-H, 2922cm -1 It is the asymmetric stretching vibration absorption peak of methylene, 2850cm -1 Closed peak for the symmetrical stretching vibration of methylene, 1664cm -1 It is the C=O stretching vibration absorption peak in the amide group, 1546cm -1 and 1471cm -1 is the asymmetric bending vibration of methylene, 1379...

Embodiment 2

[0077] (1) Preparation of secondary amide diquaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier:

[0078] 1) Add 326.0g of N-hydrogenated tallow-1,3-propylenediamine and 330g of absolute ethanol into the reactor, heat and stir to dissolve. Then, 321.2 g of N-methylolacrylamide (96% content) was added gradually, and the reaction was stirred at 70° C. for 3 h.

[0079] 2) Add 245.2g of sodium bisulfite and 785.4g of water into another reactor, stir to dissolve, and heat to 75°C. Then 197.8 g of epichlorohydrin was added dropwise, and stirred at 75° C. for 3.5 h to obtain an aqueous solution of 3-chloro-2-hydroxypropyl sulfonate sodium.

[0080] 3) The aqueous solution of sodium 3-chloro-2-hydroxypropyl sulfonate prepared in step 2) was added dropwise to the synthesis product in the above step 1), and stirred at 75° C. for 3 h. The secondary amide diquaternary ammonium salt type sodium hydroxypropyl sulfonate asphalt emulsifier was obtained, which wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com