Environment-friendly soft polyvinyl chloride hot melt pressure-sensitive adhesive tape and manufacturing method thereof

A soft polyvinyl chloride, hot-melt pressure-sensitive adhesive technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve problems such as deformation of polyvinyl chloride films, and achieve low manufacturing costs , cost reduction, and the effect of a large increase in cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

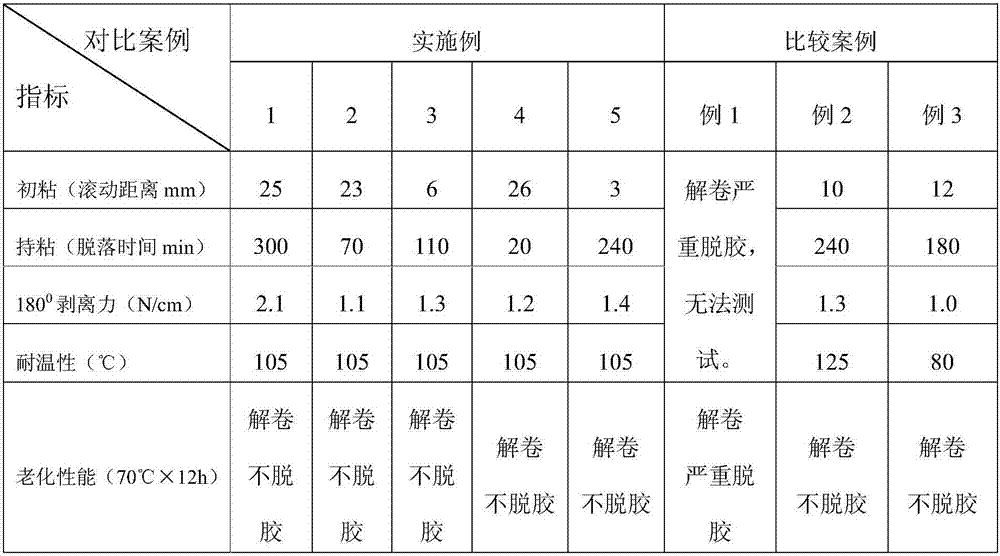

Examples

Embodiment 1

[0030] The production method of environment-friendly soft polyvinyl chloride hot-melt pressure-sensitive adhesive tape 1 is characterized in that: comprising the following steps:

[0031] 1) Take by weighing 100 parts of ethylene-based polyvinyl chloride resin powder SG-5 type, 50 parts of trioctyl trimellitate TOTM, 3 parts of powder barium zinc heat stabilizer, 5 parts of High-temperature grade color cake and 15 parts of nano-scale calcium carbonate, spare;

[0032] 2) Mix ethylene-based polyvinyl chloride resin powder, trioctyl trimellitate, powdered barium-zinc heat stabilizer, high-temperature grade color cake and nano-scale calcium carbonate through a mixer, knead with a kneader, and open the first stage of the mill Rubber mixing, filtration extrusion, first-stage rubber mixing in the open mill, and calender calendering to form polyvinyl chloride film;

[0033] 3) Take 30 parts by weight of butyl rubber 268 (IIR), 20 parts of low molecular weight polyisobutylene PIB, 35...

Embodiment 2

[0037] The production method of environment-friendly soft polyvinyl chloride hot-melt pressure-sensitive adhesive tape 2 is characterized in that: comprising the following steps:

[0038] 1) Take by weighing 150 parts of ethylene-based polyvinyl chloride resin powder SG-5 type, 30 parts of trioctyl trimellitate TOTM, 5 parts of powder barium zinc heat stabilizer, 1 part of High-temperature grade color cake and 40 parts of nano-scale calcium carbonate, standby;

[0039] 2) Mix ethylene-based polyvinyl chloride resin powder, trioctyl trimellitate, powdered barium-zinc heat stabilizer, high-temperature grade color cake and nano-scale calcium carbonate through a mixer, knead with a kneader, and open the first stage of the mill Rubber mixing, filtration extrusion, first-stage rubber mixing in the open mill, and calender calendering to form polyvinyl chloride film;

[0040] 3) Take by weighing 20 parts of butyl rubber 268 (IIR), 30 parts of low molecular weight polyisobutylene PIB,...

Embodiment 3

[0044] The production method of environment-friendly soft polyvinyl chloride hot-melt pressure-sensitive adhesive tape 3 is characterized in that: comprising the following steps:

[0045] 1) Take by weighing 50 parts of ethylene-based polyvinyl chloride resin powder SG-5 type, 70 parts of trioctyl trimellitate TOTM, 1 part of powder barium zinc heat stabilizer, 10 parts of High temperature grade color cake, spare;

[0046] 2) Mix ethylene-based polyvinyl chloride resin powder, trioctyl trimellitate, powdered barium-zinc heat stabilizer, high-temperature grade color cake and nano-scale calcium carbonate through a mixer, knead with a kneader, and open the first stage of the mill Rubber mixing, filtration extrusion, first-stage rubber mixing in the open mill, and calender calendering to form polyvinyl chloride film;

[0047] 3) Take 30 parts by weight of butyl rubber 268 (IIR), 20 parts of low molecular weight polyisobutylene PIB, 45 parts of hydrogenated styrene-butadiene block...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap