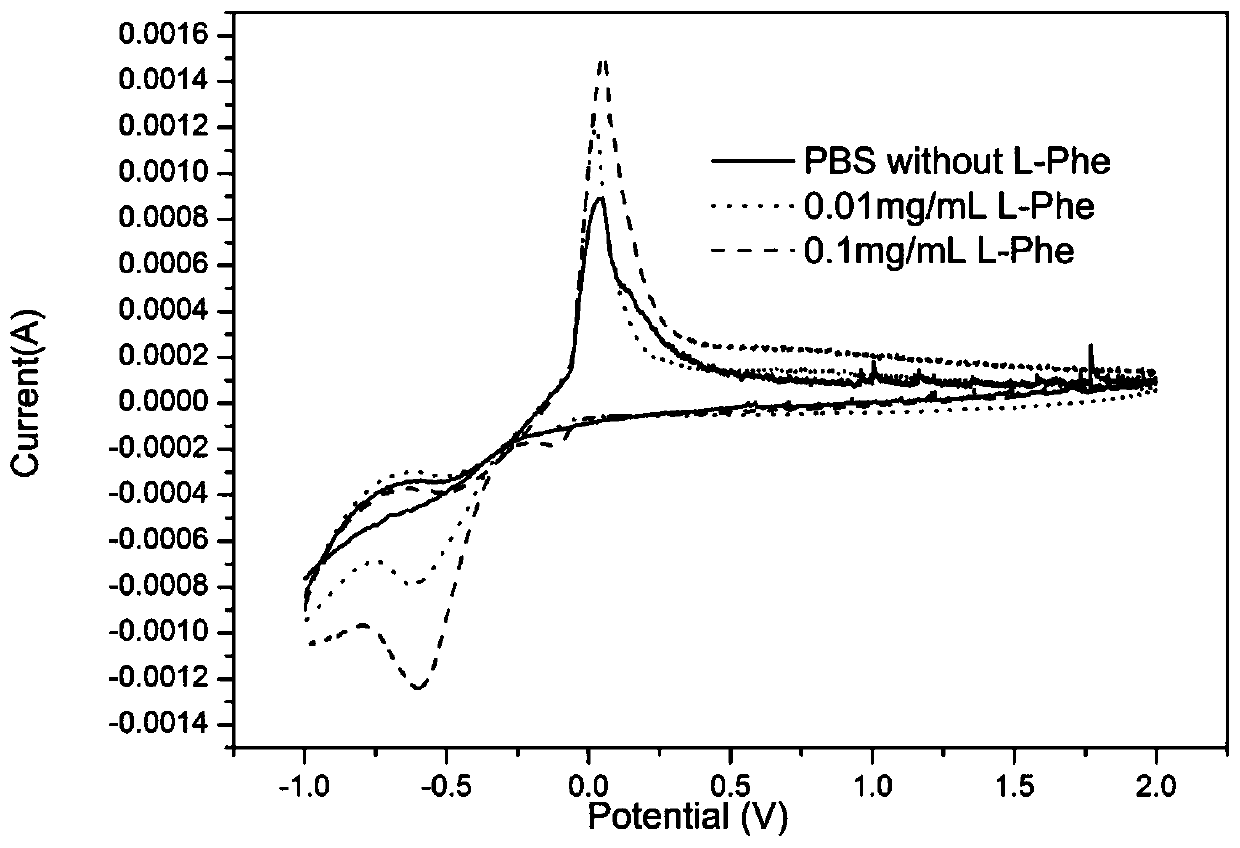

A flexible l-phenylalanine electrochemical sensor based on dendritic silver nanostructures

A phenylalanine and electrochemical technology, applied in the direction of electrochemical variables of materials, can solve the problems of difficult bending or extension of electronic devices, damage to electronic devices, etc., and achieve the effect of simple preparation process and excellent electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

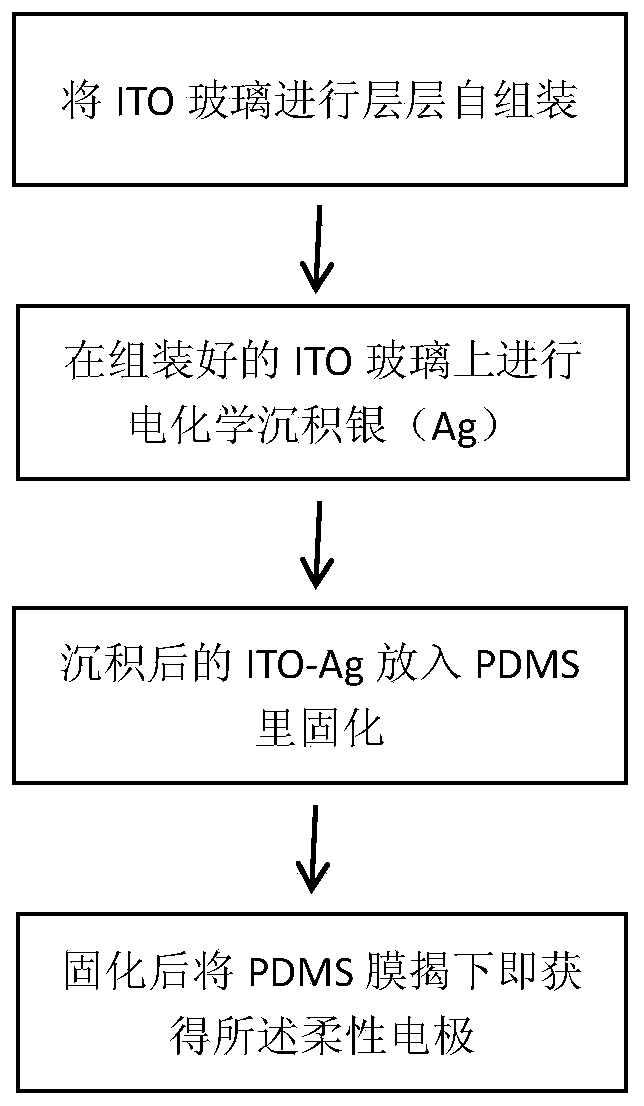

[0025] The ITO glass is self-assembled in 6 layers, and the ITO glass needs to be cleaned before assembly. The cleaning process is to ultrasonically clean the ITO glass with deionized water, acetone and ethanol for 30 minutes, respectively. After cleaning, put it into an ozone cleaner for surface hydroxylation. Then the ITO glass was self-assembled layer by layer in PDDA (polydiallyl dimethyl ammonium chloride) and PSS (polystyrene sodium sulfonate) solutions.

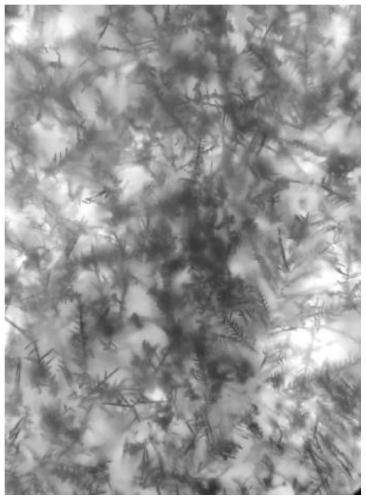

[0026] Deposit dendritic nano-silver on the assembled ITO glass, the method adopted is chronoamperometry, the reference electrode is a saturated mercurous sulfate electrode, the counter electrode is a platinum wire, the working electrode is an assembled ITO glass, and the electrolyte is AgNO 3 and NaNO 3 Mixed solution, deposition time 400s, AgNO 3 The concentration is 0.008mol / L, NaNO 3 The concentration is 0.1mol / L, and the set potential is -0.3V. Through electrochemical deposition, a white nano-silver conducti...

Embodiment 2

[0029] 6-layer self-assembly of ITO glass. ITO glass needs to be cleaned before assembly. The cleaning process is to ultrasonically clean the ITO glass with deionized water, acetone and ethanol for 30 minutes, respectively. After cleaning, put it into an ozone cleaner for surface hydroxylation. Then the ITO glass was self-assembled layer by layer in PDDA and PSS solution.

[0030] Deposit dendritic nano-silver on the assembled ITO glass, the method adopted is chronoamperometry, the reference electrode is a saturated mercurous sulfate electrode, the counter electrode is a platinum wire, the working electrode is an assembled ITO glass, and the electrolyte is AgNO 3 and NaNO 3 Mixed solution, deposition time 700s, AgNO 3 The concentration is 0.008mol / L, NaNO 3 The concentration is 0.1mol / L, and the set potential is -0.3V.

[0031] Put the silver-deposited ITO glass into the PDMS solution and put it into an oven for curing. The curing temperature is 70° C. and the curing ti...

Embodiment 3

[0033] 6-layer self-assembly of ITO glass. ITO glass needs to be cleaned before assembly. The cleaning process is to ultrasonically clean the ITO glass with deionized water, acetone and ethanol for 30 minutes, respectively. After cleaning, put it into an ozone cleaner for surface hydroxylation. Then the ITO glass was self-assembled layer by layer in PDDA and PSS solution.

[0034]Deposit dendritic nano-silver on the assembled ITO glass, the method adopted is chronoamperometry, the reference electrode is a saturated mercurous sulfate electrode, the counter electrode is a platinum wire, the working electrode is the previously assembled ITO glass, and the electrolyte is AgNO 3 and NaNO 3 Mixed solution, deposition time 800s, AgNO 3 The concentration is 0.008mol / L, NaNO 3 The concentration is 0.1mol / L, and the set potential is -0.3V.

[0035] Put the silver-deposited ITO glass into the PDMS solution and put it into an oven for curing. The curing temperature is 70° C. and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com