Phosphate binder and preparation method thereof

A phosphorus binder and mixed solution technology, which is applied in the direction of drug combination, pharmaceutical formula, carbohydrate active ingredients, etc., can solve the problems of side effects of patients, low phosphorus adsorption capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The invention provides a preparation method of a phosphorus binding agent, mixing iron salts, carbohydrates, citric acid or citrates such as (sodium citrate) or carbonates in a certain proportion to obtain the described phosphorus binding agent agent.

[0054] A preferred preparation method is as follows:

[0055] (i) providing a mixture comprising (a) carbohydrates, (b) citric acid, citrates, carbonates, or combinations thereof; and (c) water;

[0056] (ii) under alkaline conditions, adding iron salt to the mixed solution to generate a precipitate, and separating the precipitate to obtain the phosphorus binder; wherein, the pH under the alkaline condition is 4-13.

[0057] Another preferred preparation method is as follows:

[0058] Ⅰ Dissolution: Dissolve carbohydrates and weak base in distilled water, stir well, and control the temperature of the solution from room temperature to 100°C, preferably between 40°C and 100°C, more preferably between 70°C and 90°C. Weak b...

Embodiment 1

[0092] 1. Dissolve 10g of gum arabic and 2.5g of sodium citrate in 50mL of distilled water at a temperature of 90°C and stir until fully dissolved;

[0093] 2 Add 20% ferric chloride aqueous solution dropwise to the solution at a temperature of 90°C, and simultaneously add 20% NaOH aqueous solution dropwise to control the pH of the reaction solution to be 7.5-8.5 until there is obvious precipitation, stop the dropwise addition, and Stir at ℃ for 2h to obtain a reddish-brown solution;

[0094] 3 After cooling to room temperature, centrifuge to remove the solids in the solution, add 2 times the volume of 95% ethanol, centrifuge after the precipitation is complete, and wash twice with 70% ethanol to fully wash out the salt in the product;

[0095] 4 The product obtained in steps 1-3 was isolated by spray drying.

[0096] The performance of the obtained product was detected by the phosphoric acid absorbing capacity test method of the present invention.

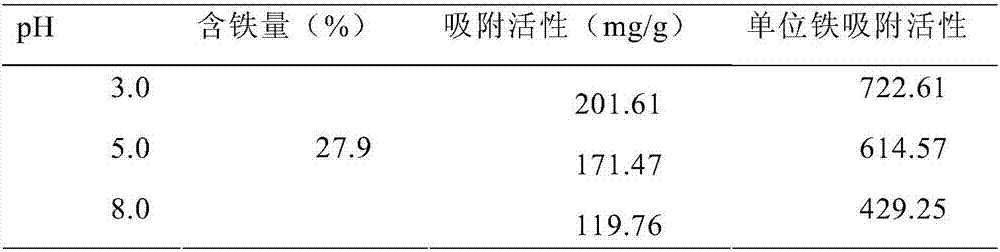

[0097] The results are s...

Embodiment 2

[0101] 1 Dissolve 100g of gum arabic, 10g of sodium citrate and 10g of sodium carbonate in 500mL of distilled water at a temperature of 90°C and stir to fully dissolve;

[0102] 2 Add 20% ferric chloride aqueous solution dropwise to the solution at a temperature of 90°C, and simultaneously add 20% NaOH aqueous solution dropwise to control the pH of the reaction solution to be 8.0-9.0 until there is obvious precipitation, stop the dropwise addition, and Stir at ℃ for 2h to obtain a reddish-brown solution;

[0103] 3 After cooling to room temperature, centrifuge to remove the solids in the solution, add 2 times the volume of 95% ethanol, centrifuge after the precipitation is complete, and wash twice with 70% ethanol to fully wash out the salt in the product;

[0104] 4 The product obtained in steps 1-3 was isolated by spray drying.

[0105] The performance of the obtained product was detected by the phosphoric acid absorbing capacity test method of the present invention.

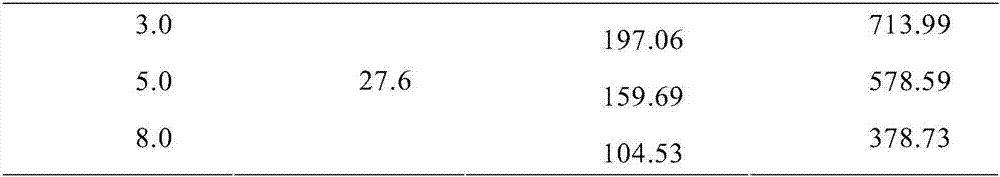

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com