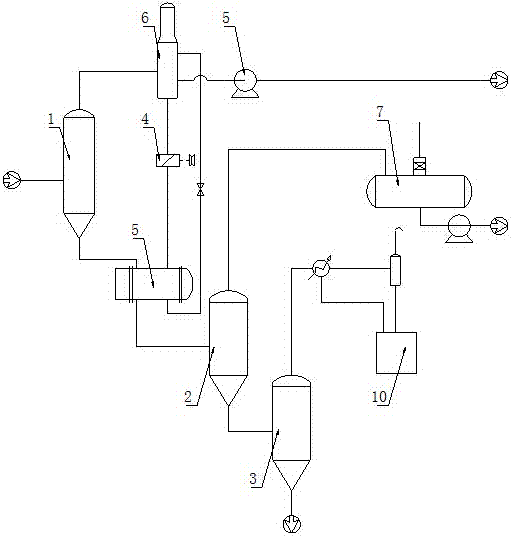

Texaco gasifier black water heat recovery and treatment system

A technology of recycling and gasification furnace, applied in the direction of degassed water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low efficiency and rough recovery method, and achieve high heat recovery and utilization efficiency, The effect of improving gas-liquid conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

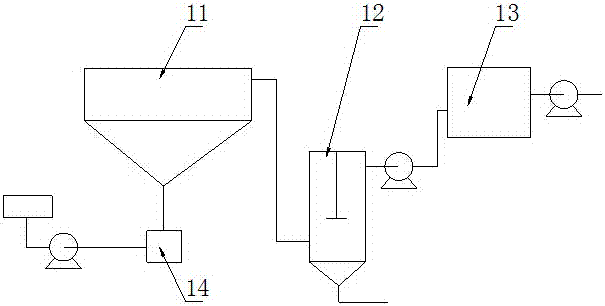

[0031] The sewage treatment system includes a primary sedimentation tank 11, a reaction sedimentation tank 12, a gray water collection tank 13 and a filter feeding tank 14. The upper outlet of the primary sedimentation tank 11 is connected to the reaction sedimentation tank 12, and the upper outlet of the reaction sedimentation tank 12 is drained through The pump is connected to the gray water collection tank 13. The outlet of the gray water collection tank 13 is connected to the gasification section. The outlet at the bottom of the primary settling tank 11 is connected to the filter feed tank 14, the outlet of the filter feed tank 14 is connected to the filter feed pump, and the outlet of the filter feed pump is connected to the roughing filter. Reactive precipitation is carried out in the ordinary sedimentation and flocculation treatment process to reduce the content of Ca2+ and Mg2+ ions in the water and avoid scaling of pipelines.

Embodiment 3

[0033] Different from Embodiment 2, the primary settling tank 11 is connected to the flocculant-adding pipeline, the reaction settling tank 12 is provided with an agitator, and the top is connected to the NaOH pipeline, NaOH pipeline, and NaOH pipeline. 2 CO 3 Pipes and flocculant pipes.

Embodiment 4

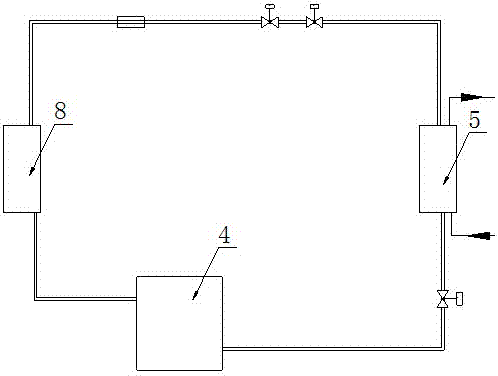

[0035] Different from Embodiment 1, a condenser is provided between the heating heat exchanger 5 and the cooling row pipe 8 . The cooling efficiency in the hot water tower 6 can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com