Method for preparing methyl alcohol and dimethyl ether by carrying out sulfur-tolerant isothermal transformation on tail gas of calcium carbide furnace

A technology of calcium carbide furnace tail gas and isothermal conversion, which is applied in the field of methanol and dimethyl ether production by temperature conversion, can solve the problems of complex process steps, small operation flexibility, and high operation intensity, and achieve advanced process technology, large operation flexibility, and simplified process The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The content of the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the embodiments of the present invention are only used to illustrate the present invention and not to limit the present invention. Without departing from the technical idea of the present invention, various replacements and changes can be made according to common technical knowledge and conventional means in the field. All should be included within the scope of the present invention.

[0057] The present invention will be further described below by specific embodiment

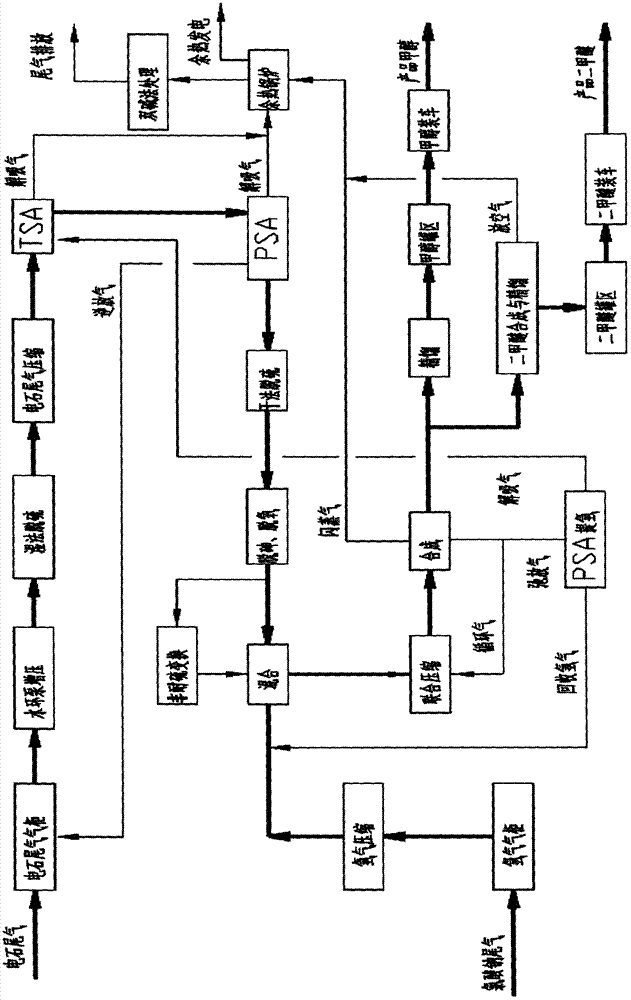

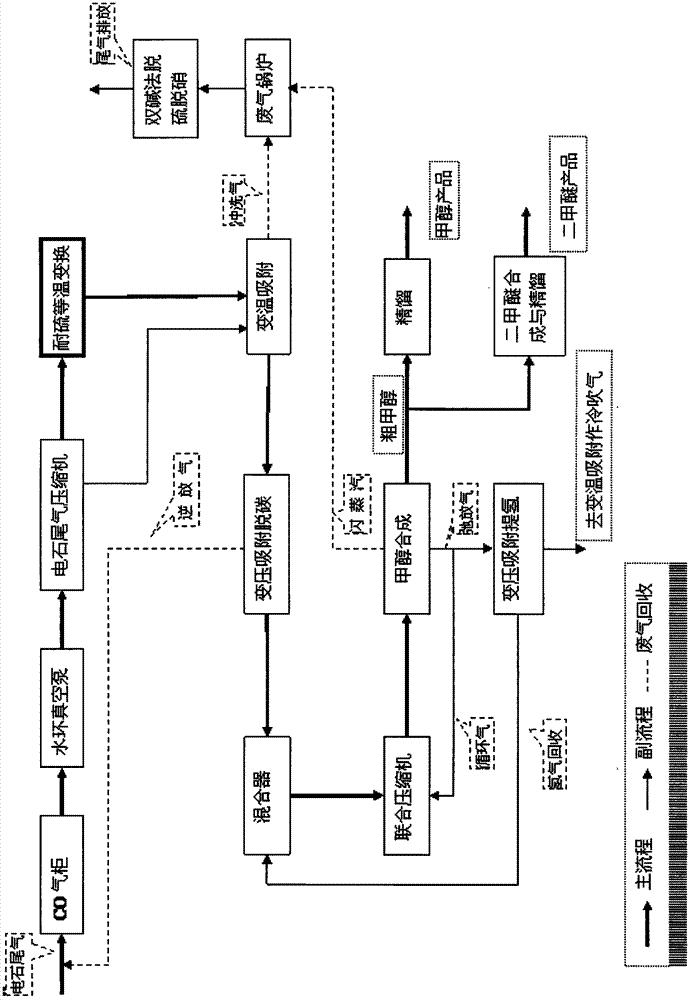

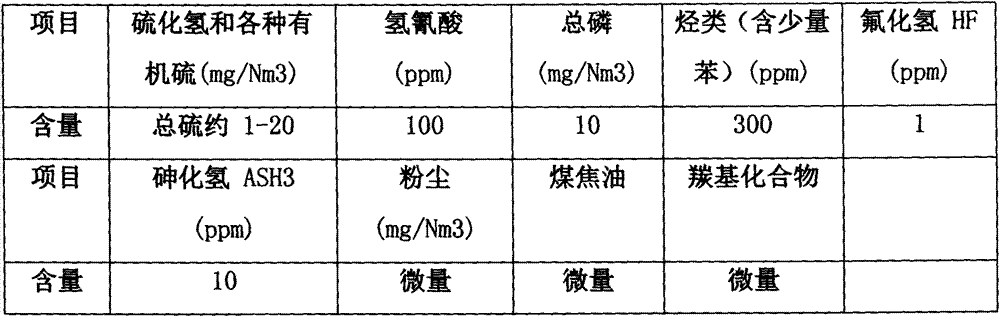

[0058] Its main steps include: water ring pump and compressor pressurization step, temperature swing adsorption purification, pressure swing adsorption purification, H 2 Mixing with CO gas in proportion, synthesis of crude methanol, purification of crude methanol, synthesis of dimethyl ether from crude methanol, synthesis of purge gas for hydrogen extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com