Method for recovering platinum group metal from spent automobile catalyst

A technology of automotive catalysts and platinum group metals, applied in the direction of improving process efficiency, etc., to achieve the effects of low reduction temperature, simple process, and easy scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

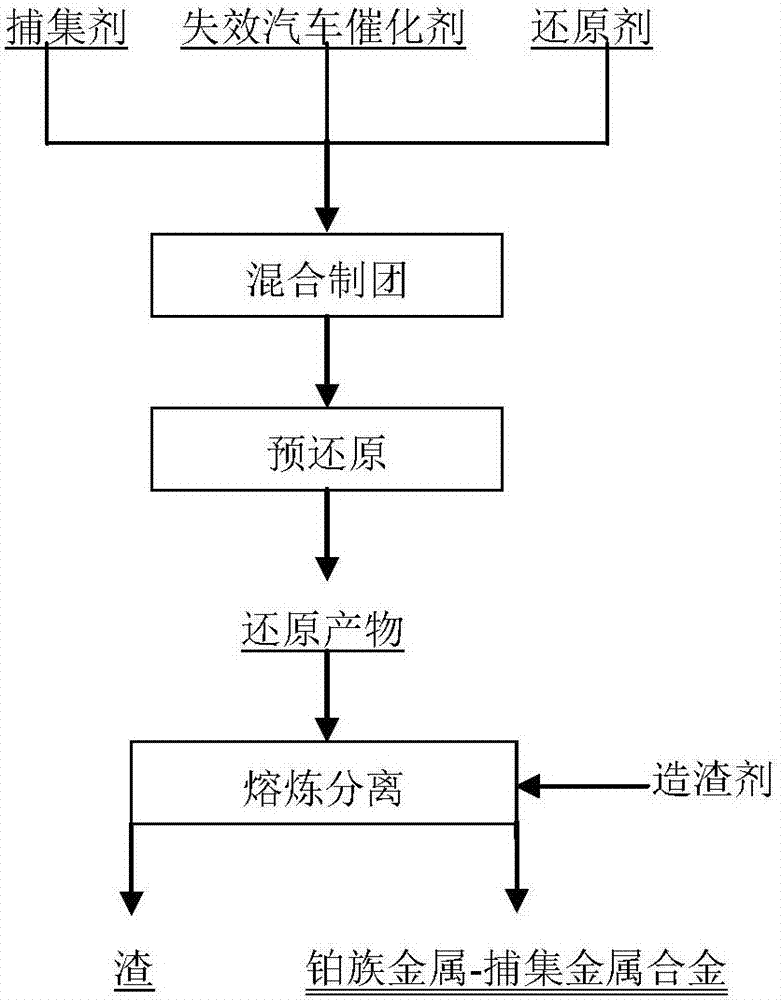

[0013] Embodiment 1, see attached figure 1 , finely ground (-0.074mm) 200g spent autocatalyst (SiO 2 33.6%, Al 2 o 3 30.3%, MgO 8.2%, Pt 221.3g / t, Pd 2259.2g / t, Rh 239.4g / t) mixed with 400g iron oxide and 50g coke powder, made into agglomerates, pre-reduced in a resistance furnace, reduced The temperature is 1000°C, the holding time is 40min, the reduction product is mixed with 60g of lime and 20g of borax and put into a crucible, placed in an intermediate frequency induction furnace for smelting for 80min, left to stand, and after cooling, the alloy phase is separated from the slag phase to obtain platinum group metals -ferroalloy. The contents of platinum, palladium and rhodium were respectively 3.1g / t, 8.7g / t and 3.8g / t in the slag sample analysis, and the recovery rates of platinum, palladium and rhodium were 97.9%, 99.2% and 97.6% respectively, and the platinum, palladium and rhodium The overall recovery was greater than 98%.

Embodiment 2

[0014] Embodiment 2, see attached figure 1 , finely ground (-0.074mm) 200g spent autocatalyst (SiO 2 33.6%, Al 2 o 3 30.3%, MgO 8.2%, Pt 221.3g / t, Pd 2259.2g / t, Rh 239.4g / t) mixed with 400g copper oxide and 40g coke powder, made into agglomerates, pre-reduced in a resistance furnace, reduced The temperature is 900°C, the holding time is 30 minutes, the reduction product is mixed with 60g of lime and 20g of borax and put into a crucible, placed in an induction furnace for smelting for 90 minutes, standing still, and after cooling, the alloy phase and slag phase are separated to obtain platinum group metals - copper alloy. The contents of platinum, palladium and rhodium were respectively 2.8g / t, 6.5g / t, and 3.2g / t in the slag sample analysis, and the recovery rates of platinum, palladium, and rhodium were 98.1%, 99.6%, and 98.0%, respectively. The overall recovery was greater than 98%.

Embodiment 3

[0015] Embodiment 3, see attached figure 1 , finely ground (-0.074mm) 200g spent autocatalyst (SiO 2 33.6%, Al 2 o 3 30.3%, MgO 8.2%, Pt 221.3g / t, Pd 2259.2g / t, Rh 239.4g / t) mixed with 500g iron oxide and 60g coke powder, made into agglomerates, pre-reduced in a resistance furnace, reduced The temperature is 1050°C, the holding time is 30 minutes, the reduction product is mixed with 80g of lime and 20g of borax and put into a crucible, placed in a high-frequency furnace for induction melting for 100 minutes, left to stand, and after cooling, the alloy phase and the slag phase are separated to obtain the platinum group Metal - iron alloy. The contents of platinum, palladium and rhodium were respectively 3.0g / t, 7.9g / t, and 3.6g / t in the slag sample analysis, and the recovery rates of platinum, palladium, and rhodium were 98.0%, 99.5%, and 97.8%, respectively. The overall recovery was greater than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com