Composite material with silicon monoxide coated with nitrogen doping carbon material and preparation method thereof

A silicon oxide, nitrogen carbon material technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve problems such as hindering graphene application, completely controlled, and incapable of electrical conductivity, and achieve buffer volume changes, increase Surface polarity, the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

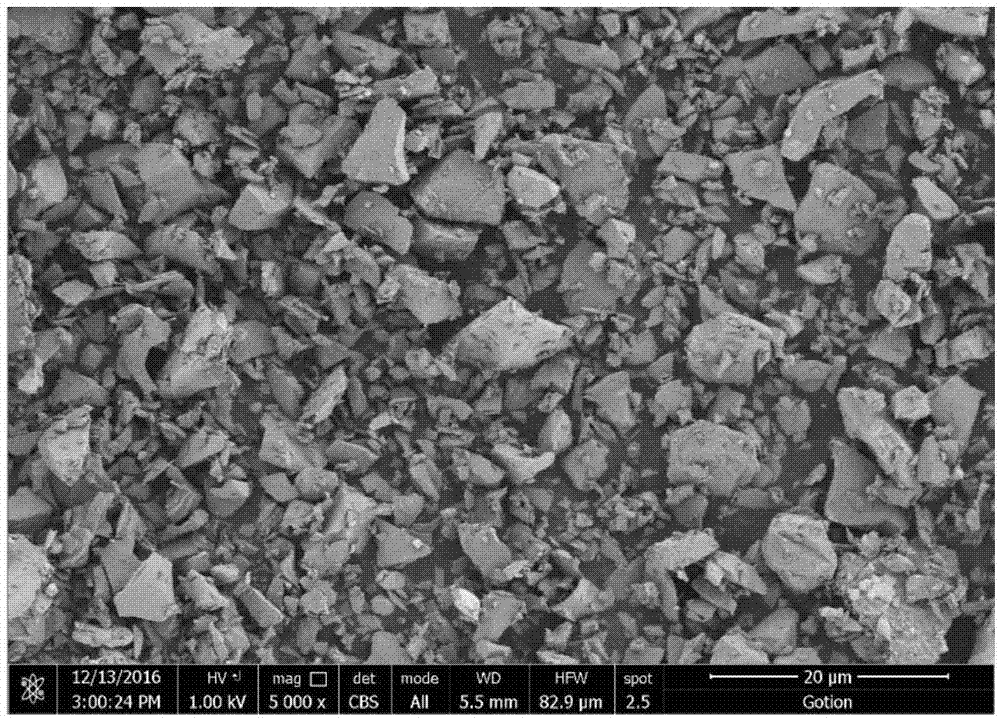

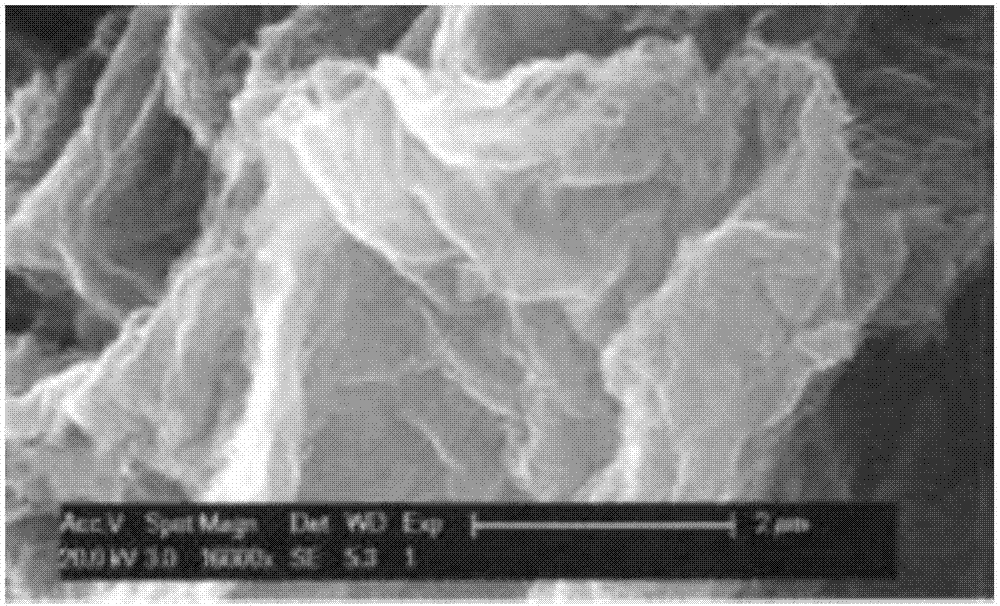

[0041] A composite material of silicon oxide coated with nitrogen-doped carbon material, with silicon oxide as the core, and silicon oxide coated with nitrogen-doped carbon material to form a core-shell structure, wherein the nitrogen-doped carbon material is nitrogen-doped graphene and A mixture of nitrogen oxide pitch; in the composite material of silicon oxide coated with nitrogen-doped carbon material, it includes: 70% silicon oxide, 20% nitrogen-doped graphene, and 10% nitrogen-doped pitch oxide;

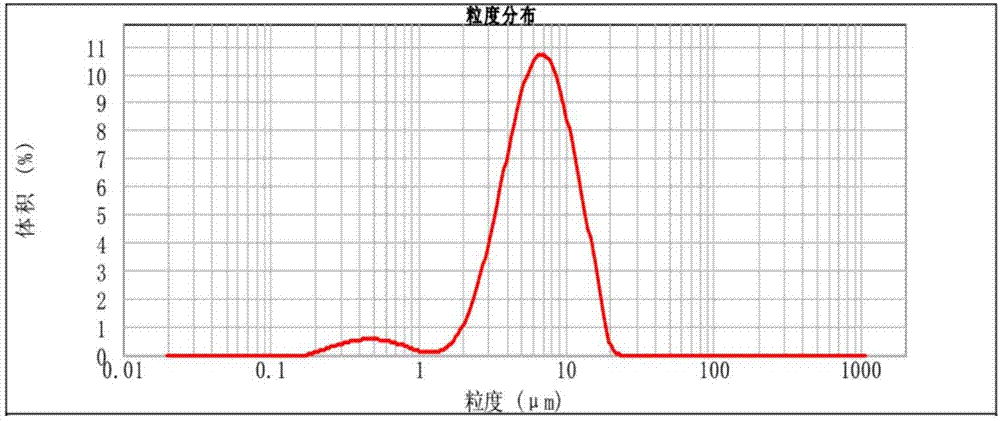

[0042] Among them, in the composite material of silicon oxide coated with nitrogen-doped carbon material, the amount of nitrogen doping is 7wt%, and the particle size D50 of silicon oxide is 4.20 μm;

[0043] The composite material of silicon oxide coated with nitrogen-doped carbon material is prepared by the following steps:

[0044]S1. Preparation of graphene oxide: put flake graphite with a particle size of 50-400 μm into a ceramic ball mill jar, add water to disperse, add c...

Embodiment 2

[0050] A composite material of silicon oxide coated with nitrogen-doped carbon material, with silicon oxide as the core, and silicon oxide coated with nitrogen-doped carbon material to form a core-shell structure, wherein the nitrogen-doped carbon material is nitrogen-doped graphene and A mixture of nitrogen oxide pitch; in the composite material of silicon oxide coated with nitrogen-doped carbon material, it includes by weight percentage: 80% silicon oxide, 10% nitrogen-doped graphene, and 10% nitrogen-doped pitch oxide;

[0051] Among them, in the composite material of silicon oxide coated with nitrogen-doped carbon material, the nitrogen doping amount is 12wt%, and the particle size D50 of silicon oxide is 6.50 μm;

[0052] The composite material of silicon oxide coated with nitrogen-doped carbon material is prepared by the following steps:

[0053] S1. Preparation of graphene oxide: put flake graphite with a particle size of 50-300 μm into a ceramic ball mill jar, add wate...

Embodiment 3

[0058] A composite material of silicon oxide coated with nitrogen-doped carbon material, with silicon oxide as the core, and silicon oxide coated with nitrogen-doped carbon material to form a core-shell structure, wherein the nitrogen-doped carbon material is nitrogen-doped graphene and A mixture of nitrogen oxide pitch; in the composite material of silicon oxide coated with nitrogen-doped carbon material, it includes: 85% silicon oxide, 10% nitrogen-doped graphene, and 5% nitrogen-doped pitch oxide;

[0059] Among them, in the composite material of silicon oxide coated with nitrogen-doped carbon material, the nitrogen doping amount is 12wt%, and the particle size D50 of silicon oxide is 8.50 μm;

[0060] The composite material of silicon oxide coated with nitrogen-doped carbon material is prepared by the following steps:

[0061] S1. Preparation of graphene oxide: put expanded graphite with a particle size of 50-300 μm into a ceramic ball mill jar, add water to disperse, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com