Simple method for preparing Co-Nx/C efficient selective photocatalyst

A photocatalyst and selective technology, applied in physical/chemical process catalysts, chemical instruments and methods, preparation of quinone oxides, etc., can solve the problems of low singlet oxygen quantum yield, low quantum yield, poor selectivity, etc. Achieve the effect of improving selective photocatalytic oxidation ability, enhancing singlet oxygen generation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

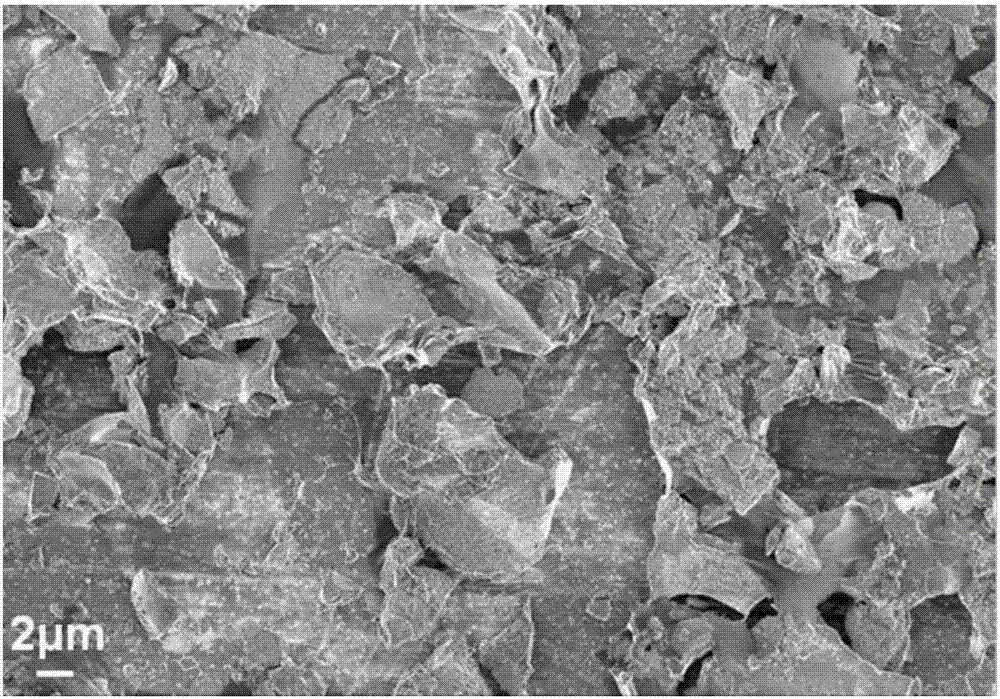

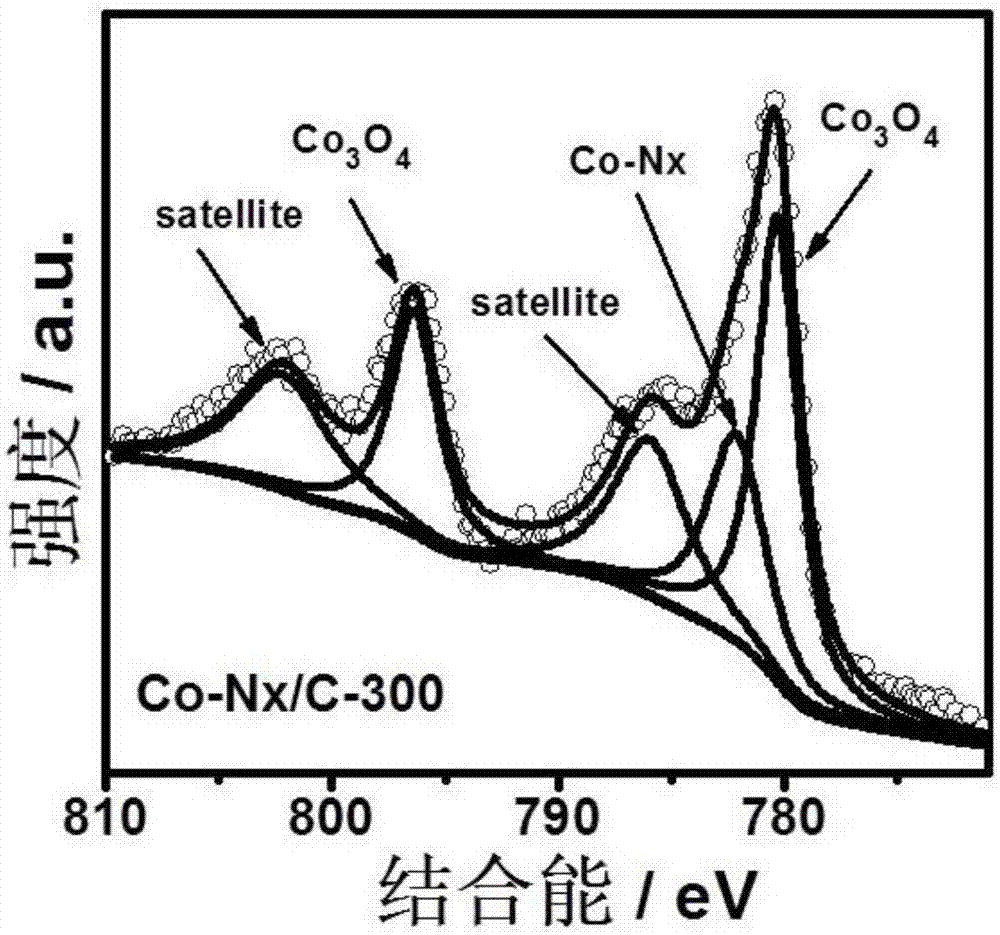

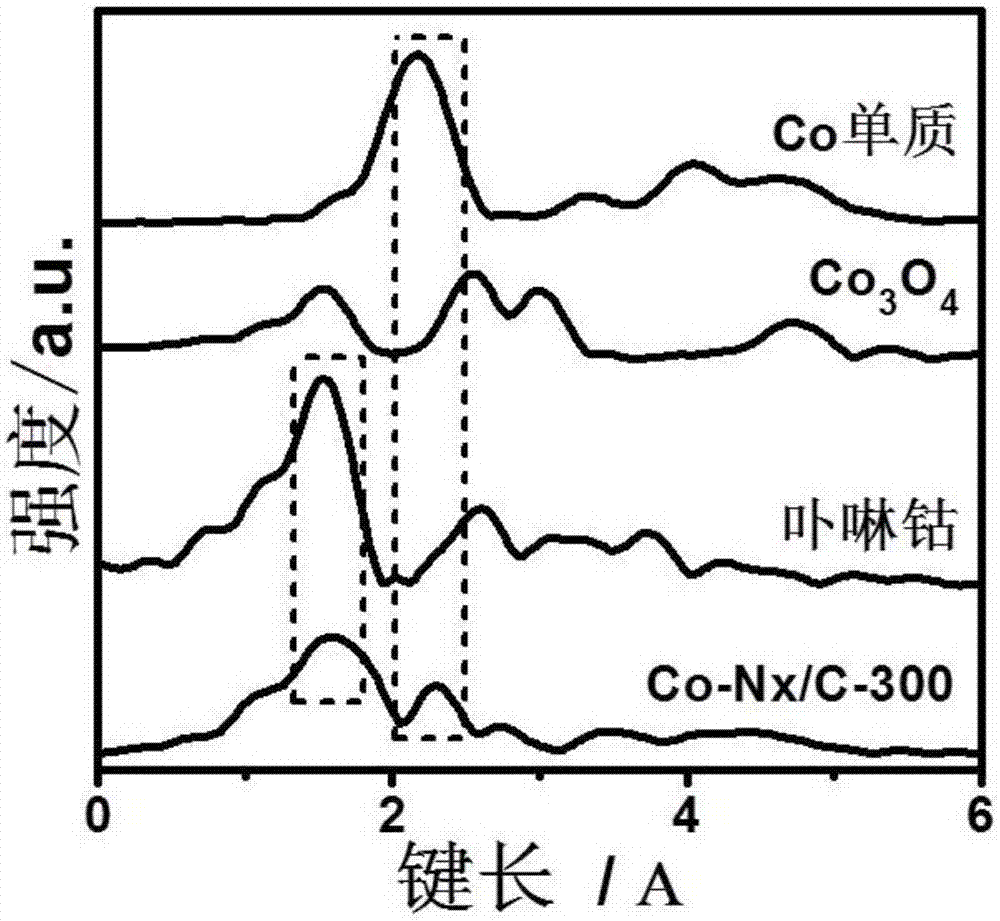

Embodiment 1

[0016] Weigh 2.75g of dimethylglyoxime and 2.5g of cobalt chloride, dissolve them in 80ml of acetone, then slowly add the cobalt chloride solution into the solution of dimethylglyoxime, and keep stirring. After stirring for 5min, the mixed solution Stand still at room temperature for 24h. Finally, the mixture was filtered to obtain a green precipitate, which was washed three times with acetone, and then vacuum-dried at 60°C to obtain the metal-organic complex precursor; weigh 2g of the metal-organic complex precursor, and evenly spread it on Quartz boat, and then put the quartz boat into the tube furnace, N 2 Replace for 30 minutes, remove the oxygen in the tube, start the heating device, and heat up at a heating rate of 5°C / min. After raising the temperature to 300°C, keep the constant temperature for 2 hours, then lower the temperature naturally, take it out after cooling down to room temperature, wash the obtained solid three times with water and ethanol, and finally put i...

Embodiment 2

[0018] According to the main process method in Example 1, the thermal polymerization temperature was changed, and the temperature was raised to 250 ° C. The prepared photocatalyst was used to catalyze 1,5-dihydroxynaphthalene. The reaction time was 100 minutes, and the yield of juglone was 18.86%. .

Embodiment 3

[0020] According to the main flow method in Example 1, the thermal polymerization temperature was changed, and the temperature was raised to 350 ° C. The prepared photocatalyst was used to catalyze 1,5-dihydroxynaphthalene. The reaction time was 100 minutes, and the yield of juglone was 24.00%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com