Film-cCoated long-acting slow-release nitrogen fertilizer containing organic matters and preparation method thereof

An organic matter and coating technology, applied in organic fertilizers, nitrogen fertilizers, layered/coated fertilizers, etc., can solve the problems of land pollution, difficulty in controlling the amount of polyurethane material added and coating rate, and high cost of production raw materials, reducing the use of , Excellent sustained release effect, the effect of short degradation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

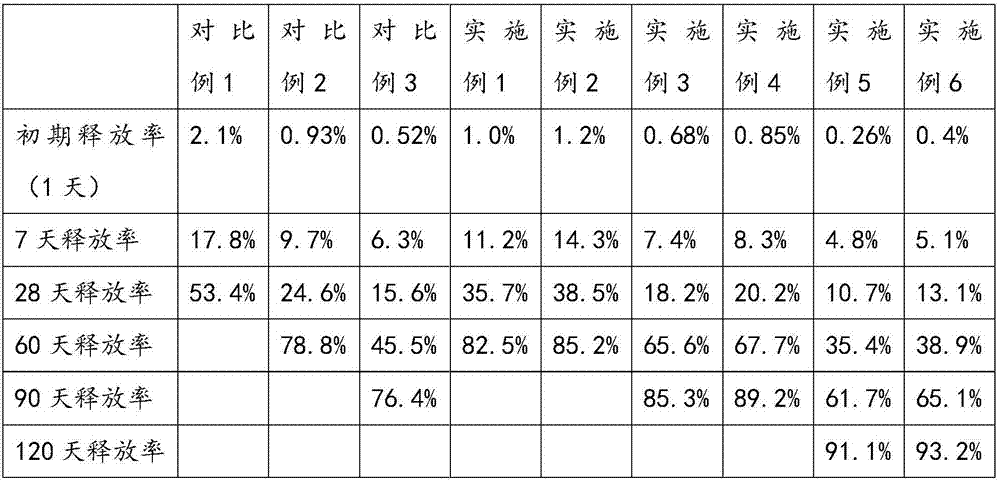

Examples

Embodiment 1

[0026] [1] According to castor oil, polypropylene glycol 400, No. 58 paraffin and triethanolamine, the polyurethane coating agent is formulated with a mass ratio of 7:1:1:0.05;

[0027] [2] According to the papermaking black liquor and polyethylene glycol 4000, the organic binder mixed solution is prepared at a mass ratio of 10:1;

[0028] [3] Add 600g of urea into the coating machine, set the speed of the coating machine to 40-50 rpm, heat up to 75°C with air blast, add 4g of polyurethane coating agent mixture and 2g of crosslinking agent isocyanate to cure for 4 minutes;

[0029] [4] Spray 6g of organic binder mixed liquid into the product obtained in step [3] and rotate for 0.5-1 minute, then add 12g of ammoniated lignite, repeat this step 3 times;

[0030] [5] After heating the product obtained in step [4] with hot air for 4 minutes and drying it, add 12 g of No. 58 paraffin wax melt and continue to rotate for 2 minutes and mix well.

Embodiment 2

[0032] [1] According to castor oil, polypropylene glycol 400, No. 58 paraffin and triethanolamine, the polyurethane coating agent is formulated with a mass ratio of 7:1:1:0.05;

[0033] [2] According to the papermaking black liquor and polyethylene glycol 4000, the organic binder mixed solution is prepared at a mass ratio of 20:1;

[0034] [3] Add 600g of urea to the coating machine, 40-50 rpm, heat up to 75°C with air blast, add 4g of polyurethane coating agent mixture and 2g of crosslinking agent isocyanate to cure for 4 minutes;

[0035] [4] Spray the product obtained in step [3] into 6g of organic binder mixed solution and rotate for 0.5-1 minute, add 12g of ammoniated lignite, repeat this step 3 times;

[0036] [5] Heat the product in step [4] with hot air for 4 minutes and dry it, then add 12g of No. 58 paraffin wax melt and continue to rotate for 2 minutes to mix.

Embodiment 3

[0038] [1] According to castor oil, polypropylene glycol 400, No. 58 paraffin and triethanolamine, the polyurethane coating agent is formulated with a mass ratio of 7:1:1:0.05;

[0039] [2] According to the papermaking black liquor and polyethylene glycol 4000, the organic binder mixed solution is prepared at a mass ratio of 10:1;

[0040] [3] Add 600g of urea to the coating machine, 40-50 rpm, heat up to 80°C with air blast, add 8g of polyurethane coating agent mixture and 4g of crosslinking agent isocyanate to cure for 4 minutes;

[0041] [4] Spray the product obtained in step [3] into 6g of papermaking black liquor and binder mixed solution and rotate for 0.5-1 minute, add 12g of ammoniated lignite, repeat this step 3 times;

[0042] [5] After heating the product obtained in step [4] with hot air for 4 minutes and drying it, add 12 g of No. 58 paraffin wax melt and continue to rotate for 2 minutes and mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com