A kind of inorganic-organic hybrid microsphere anti-bonding masterbatch

An organic hybrid, anti-adhesion technology, applied in the field of inorganic-organic hybrid microsphere anti-adhesion masterbatch, can solve the problems of low effective content, anti-adhesion particles falling off, large dosage, etc. Compatibility, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

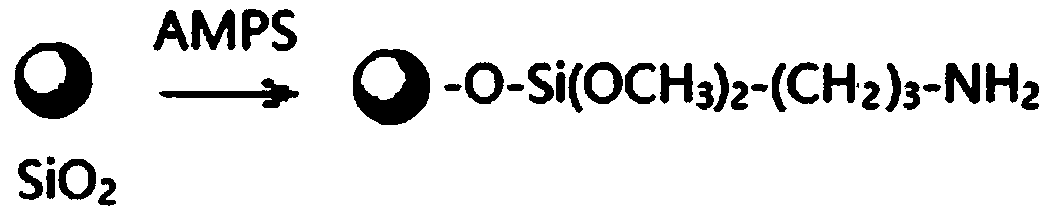

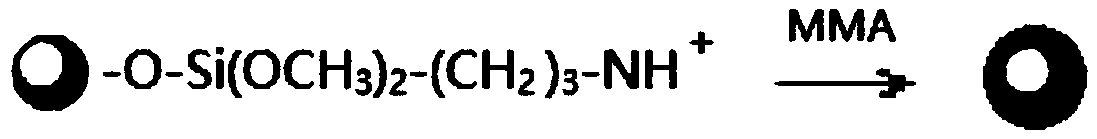

Embodiment 1

[0040] Choose silica with a particle size of 0.5-5um, and make the coupling agent γ-aminopropyltrimethoxysilane C in a solution of ethanol:water specific gravity 1:2 6 H 17 NO 3 Si grafted on silica SiO 2 On the surface, control the temperature at 25℃, react for 2h to obtain modified SiO particles 2 -C 5 H 14 NO 3 Si; then put in methacrylic acid H 2 CC(CH 3 ) COOH and persulfate, as well as crosslinking agent ethylene glycol dimethacrylate, raise the temperature to 80℃, and modify the particulate SiO 2 -C 5 H 14 NO 3 Si and persulfate form an oxidation-reduction system, methacrylic acid H 2 CC(CH 3 )COOH in SiO 2 -C 5 H 14 NO 3 The polymerization reaction on the Si surface wraps the SiO 2 -C 5 H 14 NO 3 Si, react for 8h to form inorganic-organic hybrid microsphere SiO 2 -O-Si(OCH 3 ) 2 -(CH 2 ) 3 -NH[-CH 2 CCH 3 (COOH)-] n ; After filtering and drying; Among them, methacrylic acid H 2 CC(CH 3 ) The quality of COOH is modified particulate SiO 2 -C 5 H 14 NO 3 The mass of Si is 1%, ...

Embodiment 2

[0057] Choose silica with a particle size of 0.5-10um, and make the coupling agent γ-aminopropyltrimethoxysilane C in a solution of ethanol:water specific gravity 1:1 5 H 14 NO 3 Si grafted on silica SiO 2 On the surface, control the temperature at 40℃ and react for 2h to obtain modified particulate SiO 2 -C 5 H 14 NO 3 Si; then put in methacrylic acid H 2 CC(CH 3 ) COOH and persulfate, as well as crosslinking agent ethylene glycol dimethacrylate, raise the temperature to 80℃, and modify the particulate SiO 2 -C 5 H 14 NO 3 Si and persulfate form an oxidation-reduction system, methacrylic acid H 2 CC(CH 3 )COOH in SiO 2 -C 5 H 14 NO 3 The polymerization reaction on the Si surface wraps the SiO 2 -C 5 H 14 NO 3 Si, react for 8h to form inorganic-organic hybrid microsphere SiO 2 -O-Si(OCH 3 ) 2 -(CH 2 ) 3 -NH[-CH 2 CCH 3 (COOH)-] n ; After filtering and drying; Among them, methacrylic acid H 2 CC(CH 3 ) The quality of COOH is modified particulate SiO 2 -C 5 H 14 NO 3 The mass of Si i...

Embodiment 3

[0064] Choose silica with a particle size of 0.5-10um, and make the coupling agent γ-aminopropyltrimethoxysilane C in the ethanol:water ratio 2:1 solution 5 H 14 NO 3 Si grafted on silica SiO 2 On the surface, control the temperature at 50℃ and react for 2h to obtain modified particulate SiO 2 -C 5 H 14 NO 3 Si; then put in methacrylic acid H 2 CC(CH 3 ) COOH and persulfate, as well as crosslinking agent ethylene glycol dimethacrylate, raise the temperature to 80℃, and modify the particulate SiO 2 -C 5 H 14 NO 3 Si and persulfate form an oxidation-reduction system, methacrylic acid H 2 CC(CH 3 )COOH in SiO 2 -C 5 H 14 NO 3 The polymerization reaction on the Si surface wraps the SiO 2 -C 5 H 14 NO 3 Si, react for 8h to form inorganic-organic hybrid microsphere SiO 2 -O-Si(OCH 3 ) 2 -(CH 2 ) 3 -NH[-CH 2 CCH 3 (COOH)-] n ; After filtering and drying; Among them, methacrylic acid H 2 CC(CH 3 ) The quality of COOH is modified particulate SiO 2 -C 5 H 14 NO 3 The mass of Si is 10%, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com