High-modulus polyvinyl alcohol fiber reinforced PPO/PA6 alloy and preparation method thereof

A polyvinyl alcohol fiber, high modulus technology, applied in the field of alloy preparation, can solve the problems of low strength, weak rigidity, poor heat resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

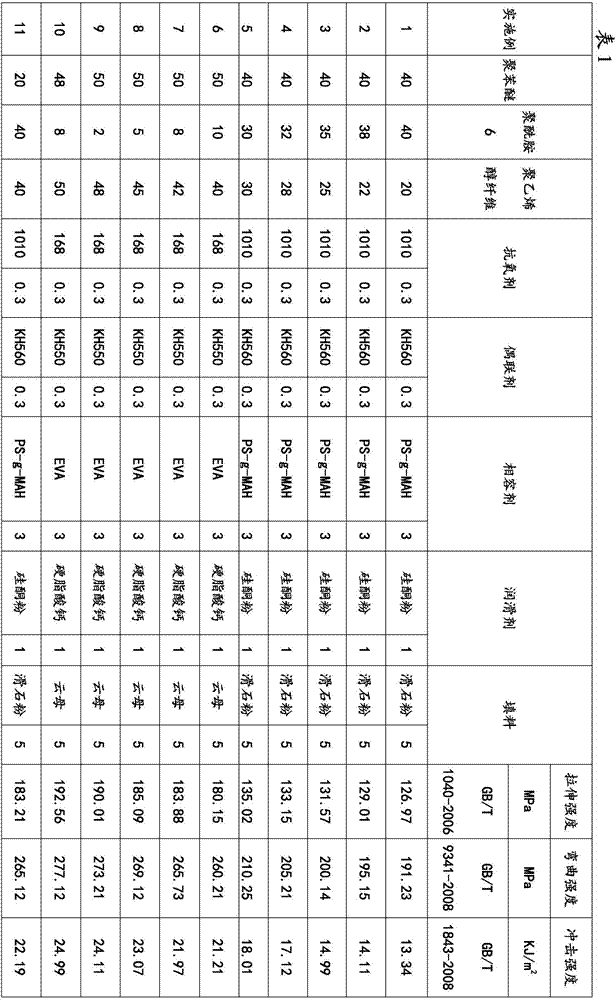

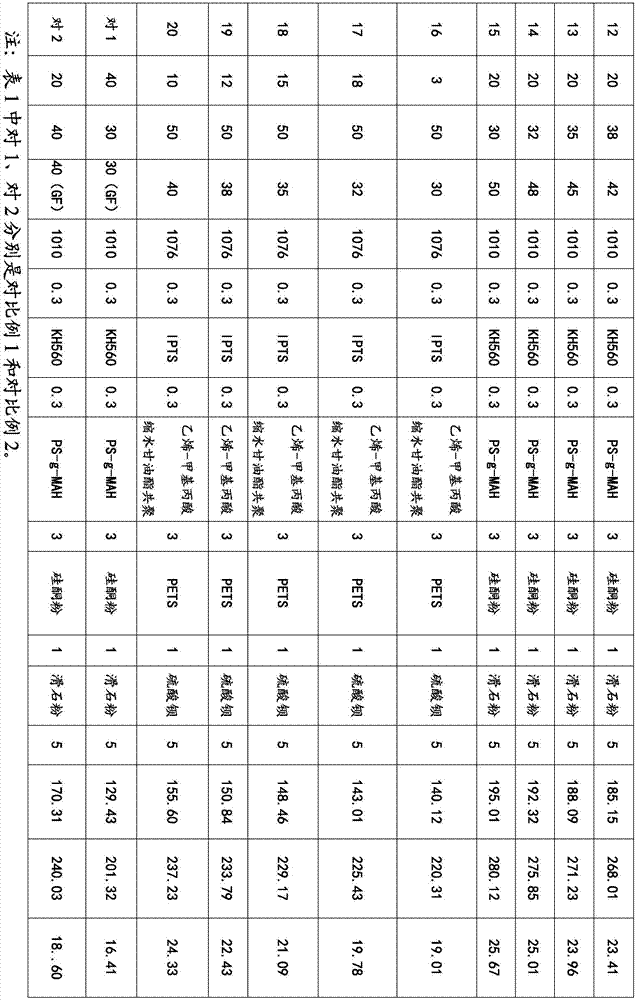

Examples

Embodiment 1

[0021] 40kg polyphenylene ether (PPO), 40kg polyamide 6 (PA6), 0.3kg antioxidant 1010, 0.3kg coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH560), 3kg compatibilizer horse Anhydride-grafted polystyrene graft (PS-g-MAH), 1kg lubricant silicone powder and 5kg filler talcum powder were added to a high-speed mixer and mixed evenly at high speed, then 20kg polyvinyl alcohol fiber was added to mix evenly at a low speed, and then extruded through a twin-screw Melting, kneading, extruding, cooling, drying, pelletizing. The temperature of each zone of the barrel of the twin-screw extruder used is kept between 230 and 260°C.

Embodiment 2

[0023] 40kg polyphenylene ether (PPO), 38kg polyamide 6 (PA6), 0.3kg antioxidant 1010, 0.3kg coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH560), 3kg compatibilizer horse Anhydride-grafted polystyrene graft (PS-g-MAH), 1kg lubricant silicone powder and 5kg filler talc powder are added to a high-speed mixer and mixed evenly at high speed, then 22kg polyvinyl alcohol fiber is added to mix evenly at a low speed, and then extruded through a twin-screw Melting, kneading, extruding, cooling, drying, pelletizing. The temperature of each zone of the barrel of the twin-screw extruder used is kept between 230 and 260°C.

Embodiment 3

[0025] 40kg polyphenylene ether (PPO), 35kg polyamide 6 (PA6), 0.3kg antioxidant 1010, 0.3kg coupling agent γ-glycidyl etheroxypropyl trimethoxysilane (KH560), 3kg compatibilizer horse Anhydride-grafted polystyrene (PS-g-MAH), 1kg lubricant silicone powder and 5kg filler talc powder were added to a high-speed mixer and mixed evenly at high speed, and then 25kg polyvinyl alcohol fibers were added to mix evenly at a low speed and then extruded through a twin-screw Melting, kneading, extruding, cooling, drying, pelletizing. The temperature of each zone of the barrel of the twin-screw extruder used is kept between 230 and 260°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com