Preparation method of carbon quantum dots and application of carbon quantum dots in biofilm imaging

A technology of carbon quantum dots and microbial biofilms, which is applied in the field of nanomaterials and biology, can solve the problems of destroying biofilms, long incubation time, and the need for cleaning, and achieve the effects of short fermentation time, short incubation time, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation of embodiment 1 lactobacillus plantarum fermented liquid

[0042] Lactobacillus plantarum LCC-605 preserved in a glycerol tube is inoculated in a liquid MRS medium at a ratio of 1-3% by volume, placed at 25-42°C for static culture for 12-24 hours, and the obtained fermentation broth is set aside.

Embodiment 2

[0043] The preparation of embodiment 2 carbon quantum dot solution

[0044] Get 30mL of the fermented liquid prepared in Example 1 and place it in a 100mL hydrothermal reactor. Put it in an oven at 120-240°C, and react for 12-48 hours. See Table 1 for specific reaction conditions. After the reaction, the residue was removed, and the remaining liquid was filtered for later use. When the reaction temperature is 200°C and the reaction time is 24h, the quantum yield of the obtained carbon quantum dots is 12%.

[0045] Table 1 Preparation of carbon quantum dots under different reaction conditions

[0046] serial number

Reaction temperature (°C)

Reaction time (h)

1

120

48

2

200

24

3

240

12

[0047] Quantum yield measurement method:

[0048] Measure the absorbance of the carbon quantum dot solution to be measured and the reference substance quinine sulfate, measure the fluorescence intensity of the carbon quantum dot solut...

Embodiment 3

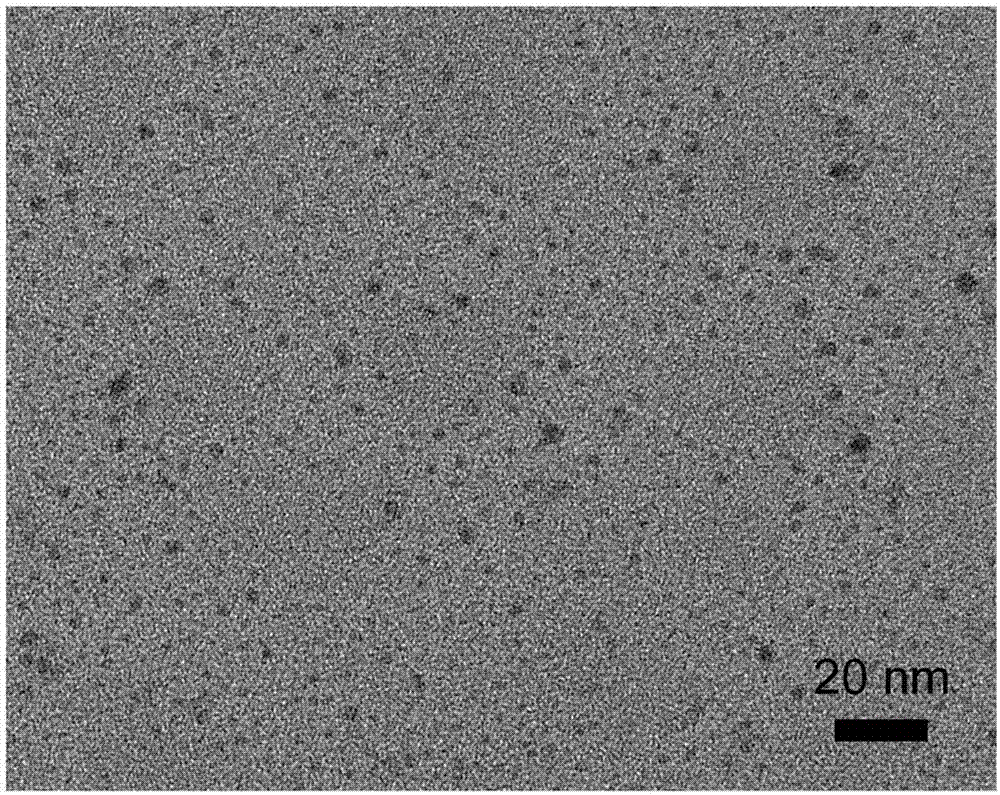

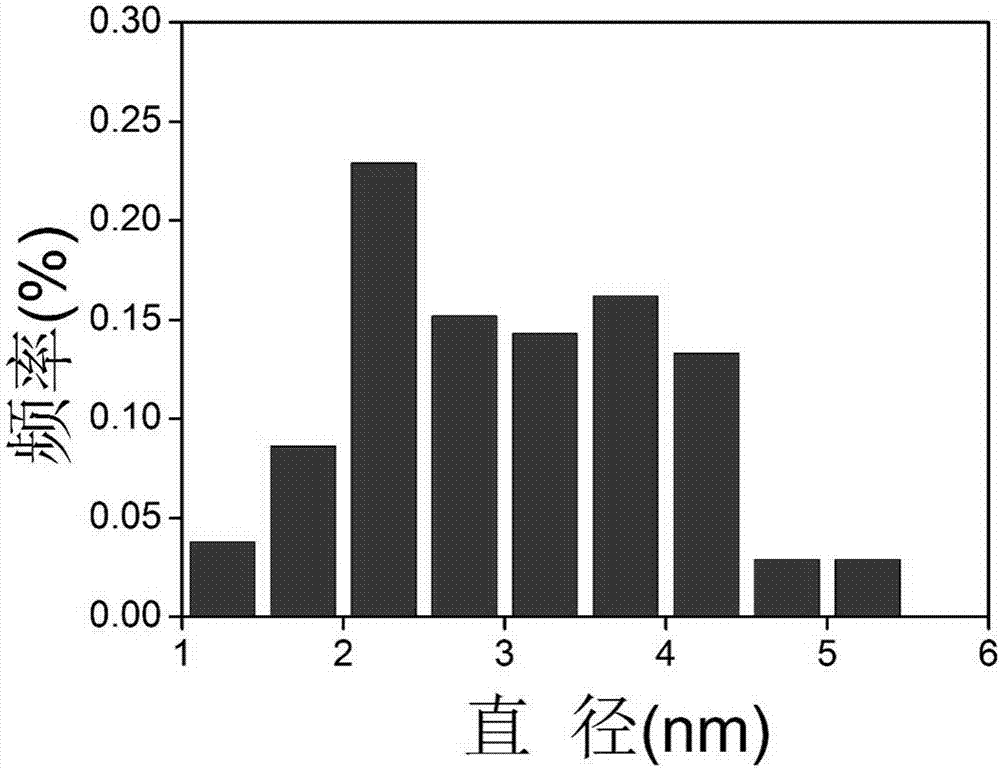

[0051] Transmission electron microscope observation of embodiment 3 carbon quantum dots

[0052] Transmission electron microscope observation of the carbon quantum dots prepared in Example 2: the filtered carbon quantum dot solution was diluted 10 times with deionized water, and 10uL was dropped on a 400-mesh copper grid, and a transmission electron microscope (JEM-2100, JEOL Ltd., Japan) for observation. The results show that the carbon quantum dots have an approximate spherical structure ( figure 1 ), the distribution is uniform, and the average particle size is about 1.6nm ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com