Polyurethane foam

A polyurethane foam and polyester polyol technology, applied in the field of polyurethane foam, can solve the problems of poor low-temperature characteristics, unsuitable for sound insulation materials, and fragile foam, and achieve good heat resistance and flame retardancy, light weight and easy handling , good moisture and heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

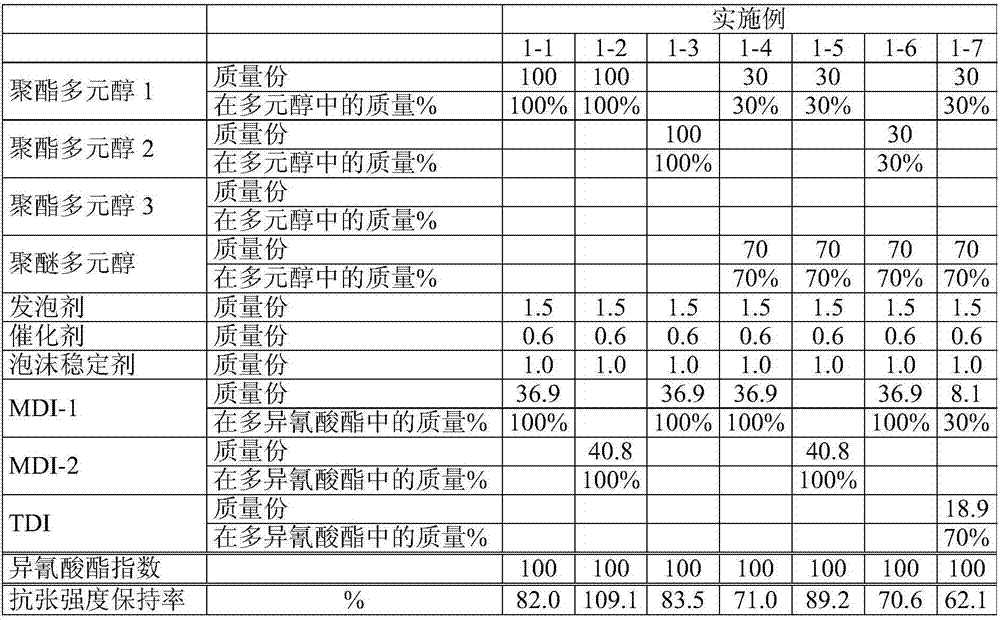

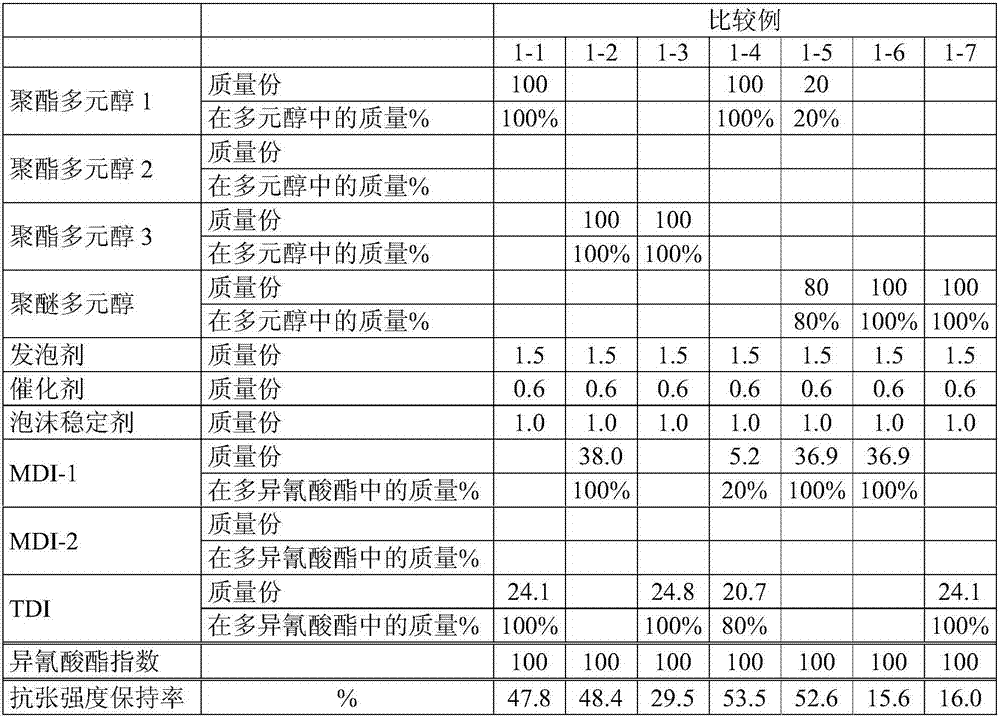

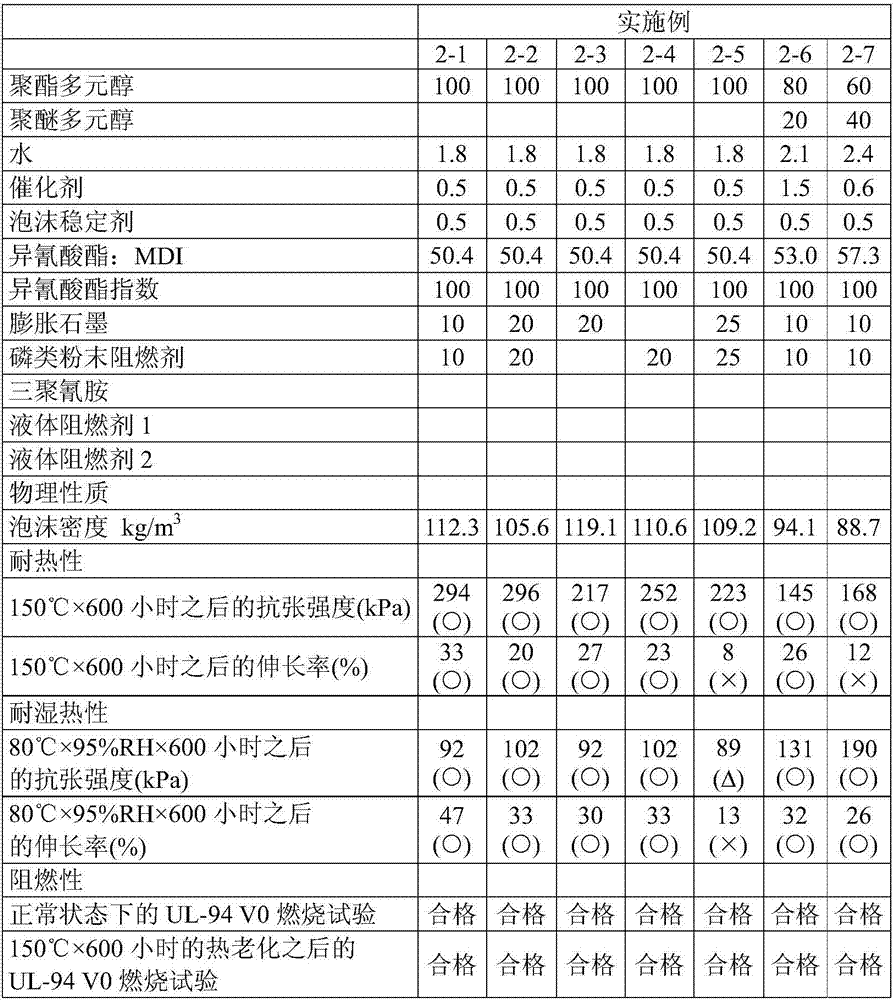

[0093] Examples and Comparative Examples of the First Invention

[0094] Polyurethane raw materials prepared as compounded as shown in each of Tables 1 and 2 were mixed in a mixer, loaded into a foaming mold of 400×400×40 mm, and foamed to produce each embodiment of the first invention Examples and comparative examples of polyurethane foam.

[0095] - Polyester polyol-1: poly(3-methyl-1,5-pentanediol; trimethylolpropane) alternately - adipic acid, molecular weight: 3000, number of functional groups: 3

[0096] - Polyester polyol-2: poly(neopentyl glycol; trimethylolpropane) alternately - adipic acid, molecular weight: 3000, number of functional groups: 3

[0097] -Polyester polyol-3: poly(diethylene glycol / trimethylolpropane) alternating-adipic acid, molecular weight: 2400, number of functional groups: 2.6

[0098] - Polyether polyol: polyoxyethylene / oxypropylene ether polyol, molecular weight: 3000, number of functional groups: 3,

[0099] - Blowing agent: water

[0100] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com