Adsorbent material and preparation method thereof

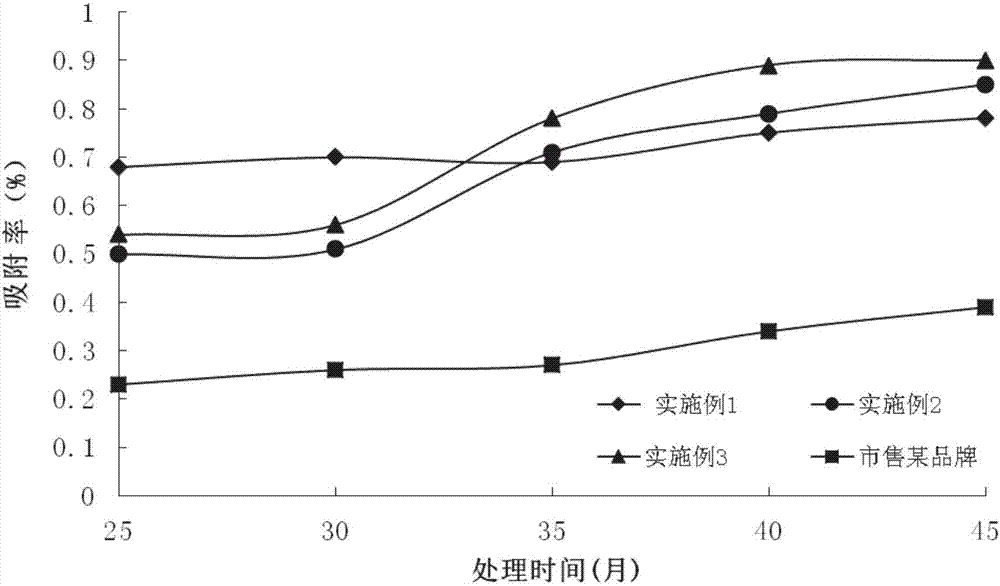

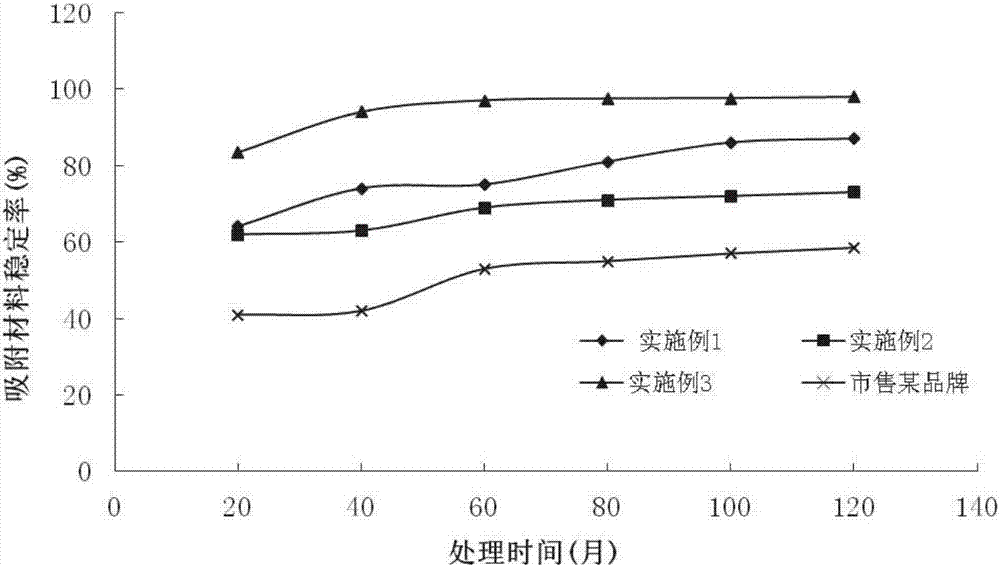

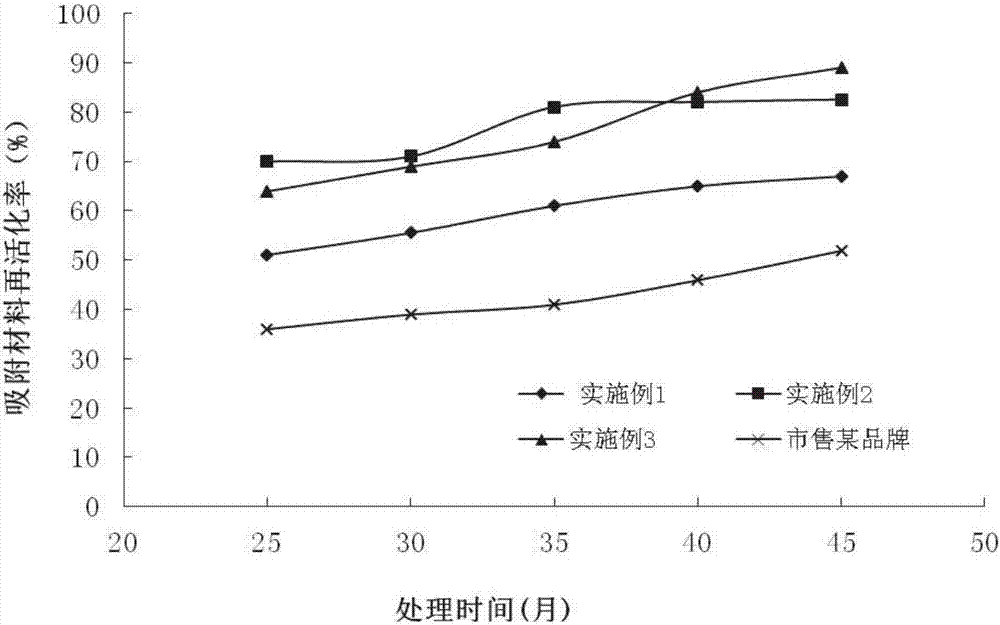

A technology of adsorption materials and stirred reactors, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as poor adsorption effect of carbon tetrachloride, and achieve novel preparation process and reactivation High efficiency and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An adsorption material, which is composed of the following components in proportion by weight: 248 parts of calcium-free magnesium water, 40 parts of fatty alcohol polyoxyethylene polyoxypropylene ether carboxylate, di(2-ethylhexyl succinate) ) 43 parts of sodium sulfonate, 39 parts of N-ethyl-p-toluenesulfonamide, 2,2,2-trifluoro-N, 42 parts of N-bis(trimethylsilyl)acetamide, 2-[[4-(cyclo 45 parts of sodium hexylamino)-9,10-dihydro-9,10-dioxo-1-anthracenyl]amino]-5-ethoxybenzenesulfonate, 47-102 parts of cesium nanoparticles, 1-amino -40 parts of 4-phenylamino-2-bromoanthraquinone, 2-[[4-[(2-chloro-4-nitrophenyl)azo]phenyl]ethylamino]-N,N,N-tri 42 parts of methyl ethyl ammonium methyl sulfate, 42 parts of anthraquinone-1-amino-5-ammonium sulfonate, 39 parts of 3,5-dimethoxyaniline, 3-[[2,5-dimethoxy- 30 parts of potassium sodium 4-[[2-(sulfooxy)ethyl]sulfonyl]phenyl]azo]-4-hydroxy-6-[(sulfophenyl)amino]-2-naphthalenesulfonate , 31 parts of 1-amino-2-methylanthraquino...

Embodiment 2

[0034] An adsorption material, which is composed of the following components in proportion by weight: 473 parts of calcium-free magnesium water, 82 parts of fatty alcohol polyoxyethylene polyoxypropylene ether carboxylate, di(2-ethylhexyl succinate) ) 152 parts of sodium sulfonate, 56 parts of N-ethyl-p-toluenesulfonamide, 2,2,2-trifluoro-N, N-bis(trimethylsilyl)acetamide 99 parts, 2-[[4-(cyclo Hexylamino)-9,10-dihydro-9,10-dioxo-1-anthracenyl]amino]-5-ethoxybenzenesulfonate 106 parts, cesium nanoparticles 102 parts, 1-amino-4 -82 parts of phenylamino-2-bromoanthraquinone, 2-[[4-[(2-chloro-4-nitrophenyl)azo]phenyl]ethylamino]-N,N,N-trimethyl 82 parts of ethyl ammonium methyl sulfate, 65 parts of anthraquinone-1-amino-5-ammonium sulfonate, 84 parts of 3,5-dimethoxyaniline, 3-[[2,5-dimethoxy-4- [[2-(sulfooxy)ethyl]sulfonyl]phenyl]azo]-4-hydroxy-6-[(sulfophenyl)amino]-2-naphthalenesulfonate potassium sodium 73 parts, 1 -67 parts of amino-2-methylanthraquinone, 93 parts of N-met...

Embodiment 3

[0044] An adsorption material, which is composed of the following components in proportion by weight: 350 parts of calcium-free magnesium water, 60 parts of fatty alcohol polyoxyethylene polyoxypropylene ether carboxylate, di(2-ethylhexyl succinate) 105 parts of sodium sulfonate, 46 parts of N-ethyl p-toluenesulfonamide, 2,2,2-trifluoro-N, 70 parts of N-bis(trimethylsilyl)acetamide, 2-[[4-(cyclo Hexylamino)-9,10-dihydro-9,10-dioxo-1-anthracenyl]amino]-5-ethoxybenzenesulfonate 75 parts, cesium nanoparticles 72 parts, 1-amino-4 -68 parts of phenylamino-2-bromoanthraquinone, 2-[[4-[(2-chloro-4-nitrophenyl)azo]phenyl]ethylamino]-N,N,N-trimethyl 57 parts of ethyl ammonium methyl sulfate, 55 parts of anthraquinone-1-amino-5-ammonium sulfonate, 62 parts of 3,5-dimethoxyaniline, 3-[[2,5-dimethoxy-4- 50 parts of potassium sodium [[2-(sulfooxy)ethyl]sulfonyl]phenyl]azo]-4-hydroxy-6-[(sulfophenyl)amino]-2-naphthalenesulfonate, 1 -48 parts of amino-2-methylanthraquinone, 69 parts of N-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com