Method for alkali metal ions to assist transitional metal chalcogenides in growth

A technology of alkali metal ions and chalcogen compounds, applied in the field of materials, can solve the problems of long growth time, poor quality, small sample size, etc., and achieve the effect of efficient growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

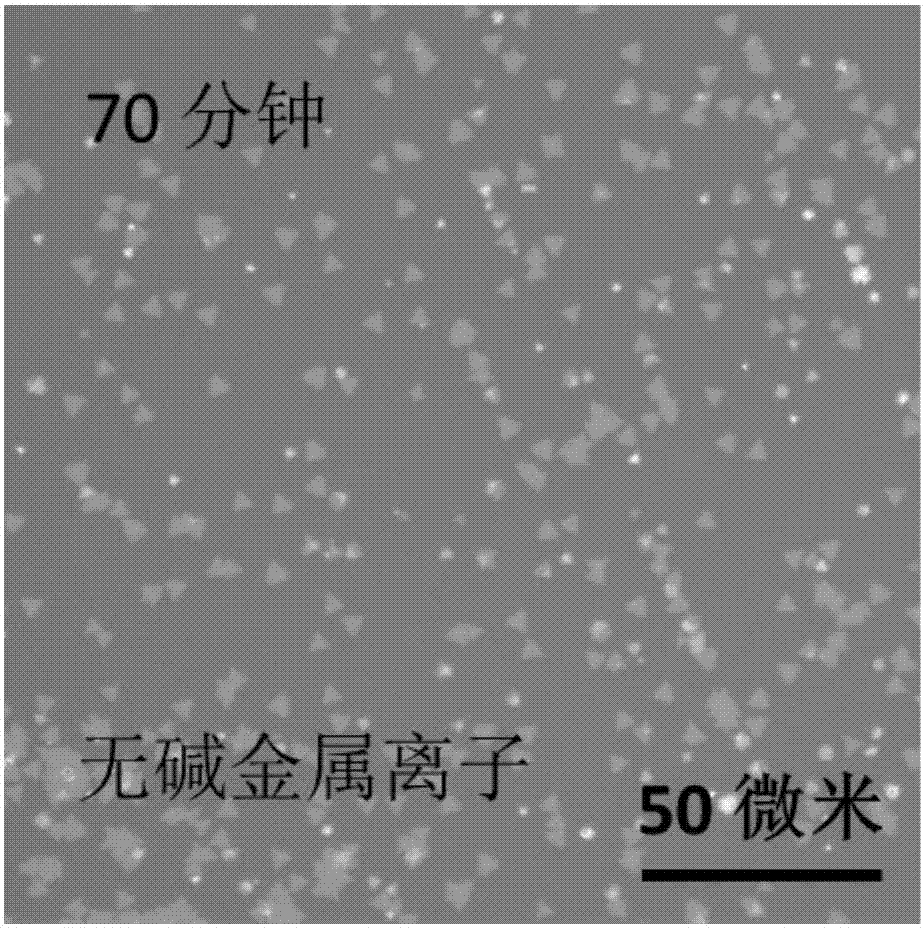

Embodiment 1

[0041] Clean the purchased quartz glass (1cm×1cm, thickness 2mm). The cleaning method is: place the quartz glass in deionized water (18.2MΩ cm), acetone (analytical pure) and isopropanol (analytical pure) in sequence. Ultrasonic cleaning was performed for 10 minutes, followed by drying with high-purity nitrogen to complete the cleaning. Put the cleaned quartz glass on the graphite boat, place a molybdenum foil with the same size as the substrate 10mm above the graphite boat, place them together in a high-temperature tubular reactor, and place 100g of elemental sulfur powder at 15cm upstream of the airflow relative to the substrate , and feed high-purity argon (50 sccm) to flush the reaction chamber for 10 minutes to remove residual air in the chamber. Then start the heating program to heat the reaction chamber. The final temperatures of the sulfur powder and the substrate are 100°C and 730°C respectively, the heating time is 35 minutes, and the temperature is kept constant for...

Embodiment 2

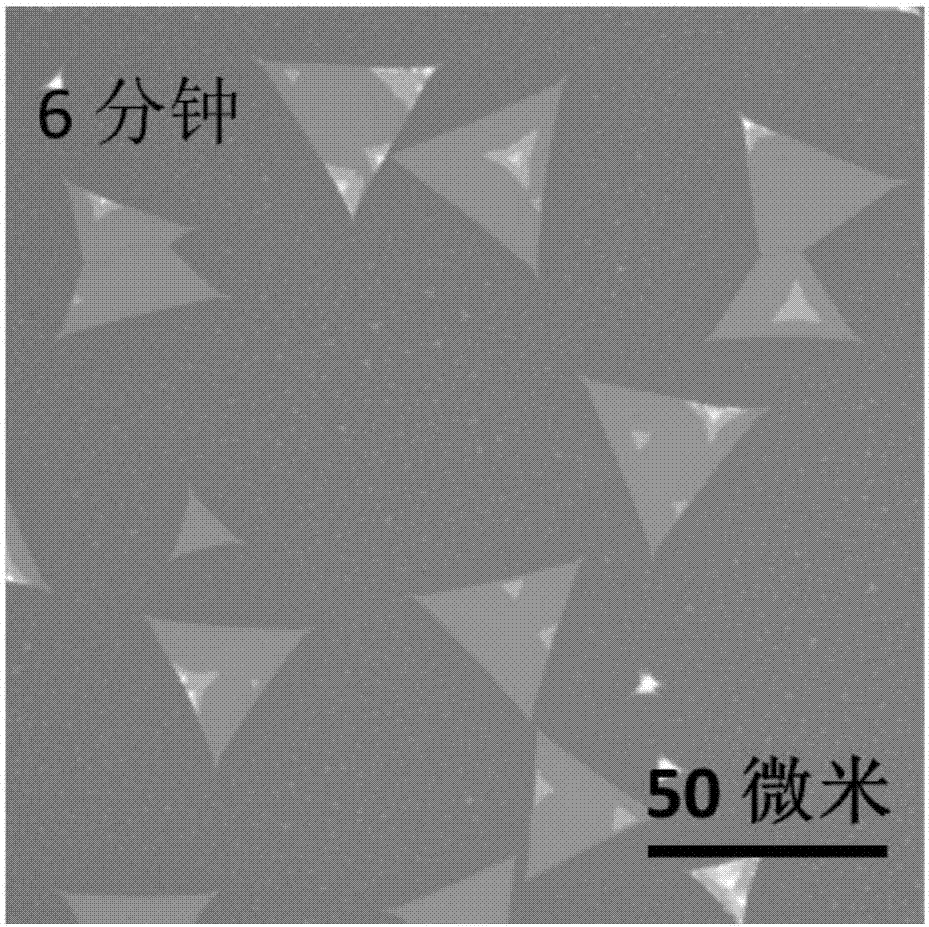

[0044]Clean the purchased quartz glass (1cm×1cm, thickness 2mm) by placing the glass in deionized water (18.2MΩ·cm), acetone (analytical grade) and isopropanol (analytical grade) in turn. Ultrasonic cleaning for 10 minutes, followed by drying with high-purity nitrogen to complete the cleaning. The purchased soda-lime glass (1 cm×1 cm) was placed on a graphite boat together with the cleaned quartz glass, and the soda-lime glass was placed upstream of the gas flow of the quartz glass. Place a molybdenum foil with the same size as the substrate at 10mm above the graphite boat, place them together in a high-temperature tubular reactor, place 100g of elemental sulfur powder at 15cm upstream of the airflow relative to the substrate, and feed high-purity argon (50sccm) Flush the reaction chamber for 10 minutes to remove residual air in the chamber. Then start the heating program to heat the reaction chamber, the final temperatures of the sulfur powder and the substrate are 100°C and...

Embodiment 3

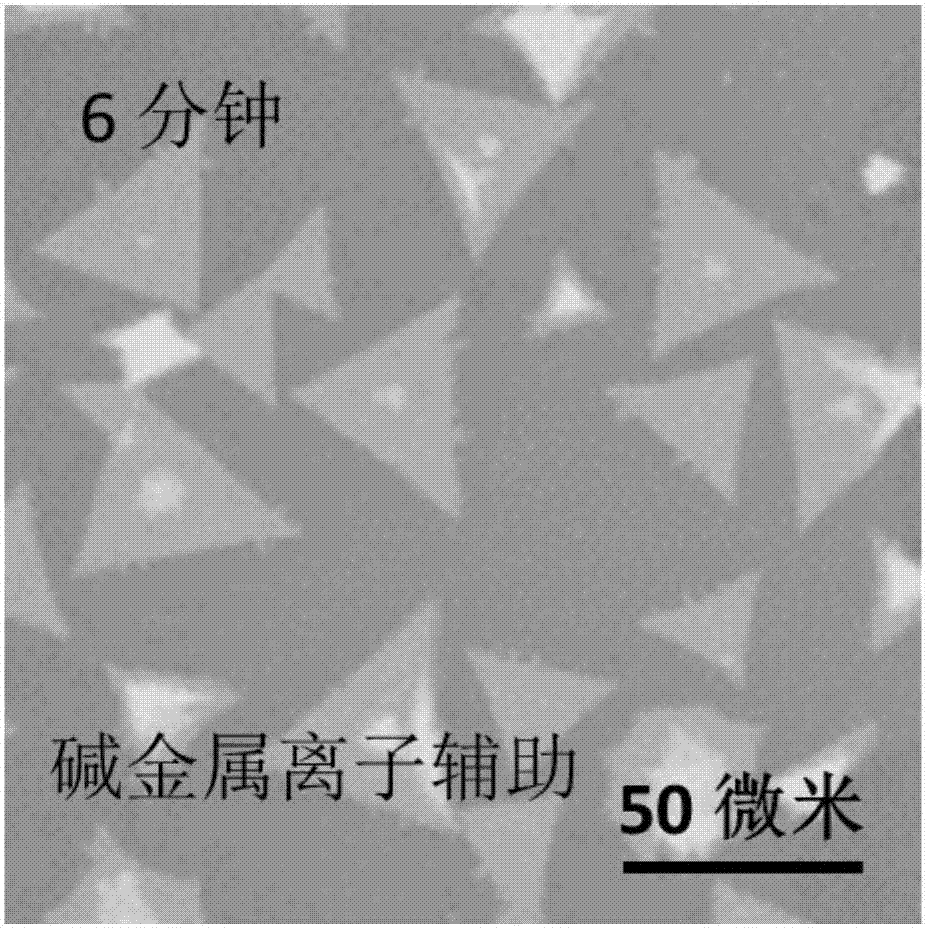

[0047] Clean the purchased quartz glass (1cm×1cm, thickness 2mm) by placing the glass in deionized water (18.2MΩ·cm), acetone (analytical grade) and isopropanol (analytical grade) in turn. Ultrasonic cleaning for 10 minutes, followed by drying with high-purity nitrogen to complete the cleaning. Prepare a sodium chloride solution with a solution mass fraction of 0.01g / ml, spin-coat 0.1ml of the sodium chloride solution on the surface of quartz glass with a rubber dropper, and place it on a graphite boat. Place a molybdenum foil with the same size as the substrate at 10mm above the graphite boat, place them together in a high-temperature tubular reactor, place 100g of elemental sulfur powder at 15cm upstream of the airflow relative to the substrate, and feed high-purity argon (50sccm) Flush the reaction chamber for 10 minutes to remove residual air in the chamber. Then start the heating program to heat the reaction chamber, the final temperatures of the sulfur powder and the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com