Perovskite solar cell having compact film of silver/titanium dioxide nanometer composite material

A nano-composite material and solar cell technology, applied in the field of solar cells, can solve the problems such as the inability to effectively improve the photoelectric conversion efficiency, and achieve the effects of easy and feasible operation, simple method and flexible application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

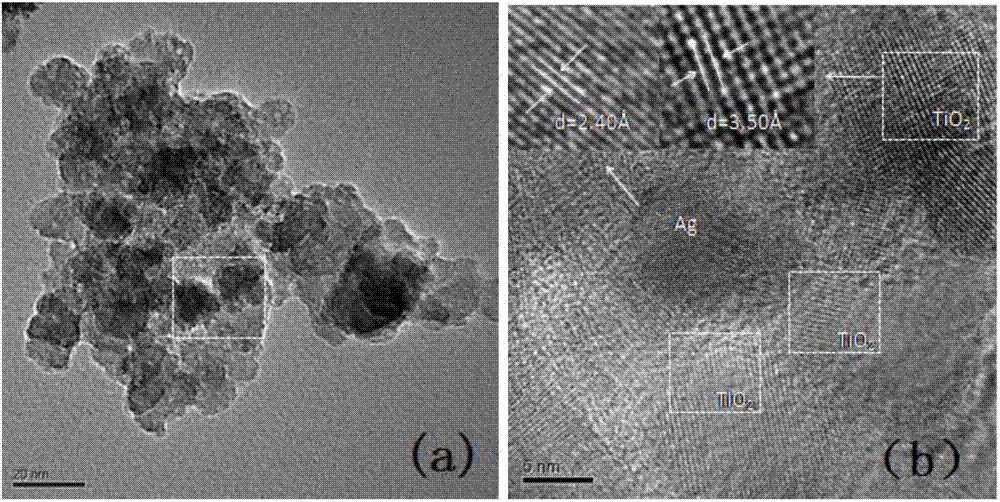

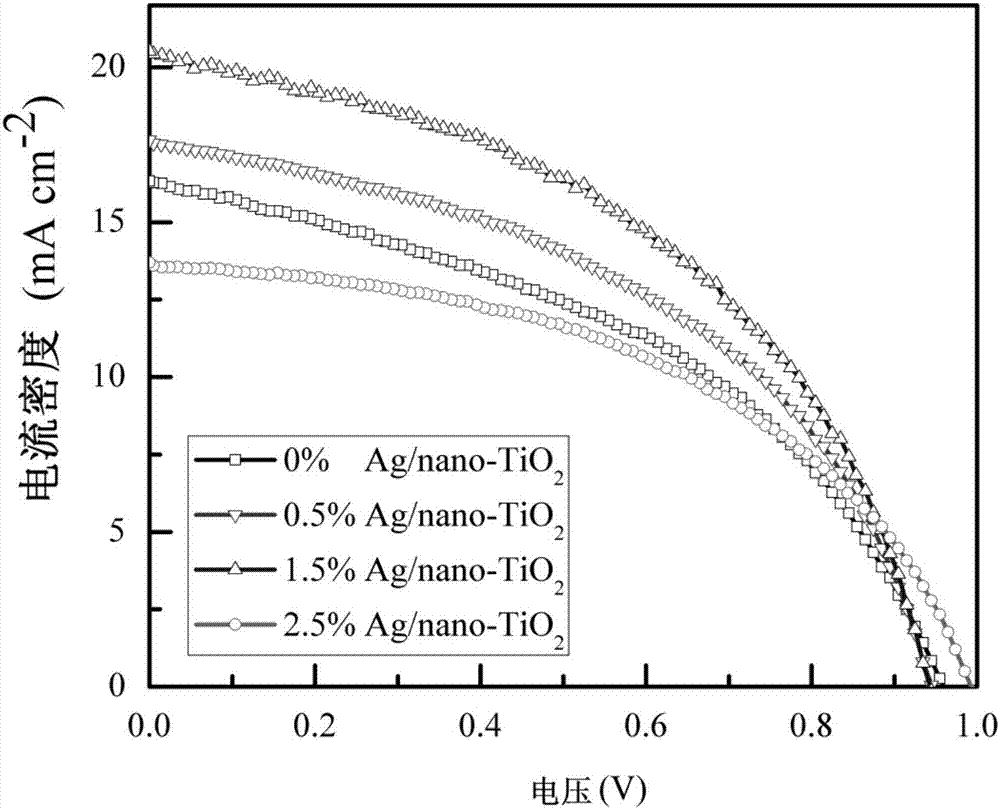

[0025] Silver nitrate and titanium dioxide were mixed at a silver-titanium molar ratio of 2.5%, and ethanol was used as a solvent to stir at a constant speed for 1 hour to prepare a dense layer precursor colloidal solution.

[0026] Clean the FTO conductive glass substrate, spin-coat a dense layer precursor solution containing silver nitrate on it, heat at 150°C for 10 minutes, spin coat once after cooling, and heat at 500°C for 30 minutes to obtain a dense layer film.

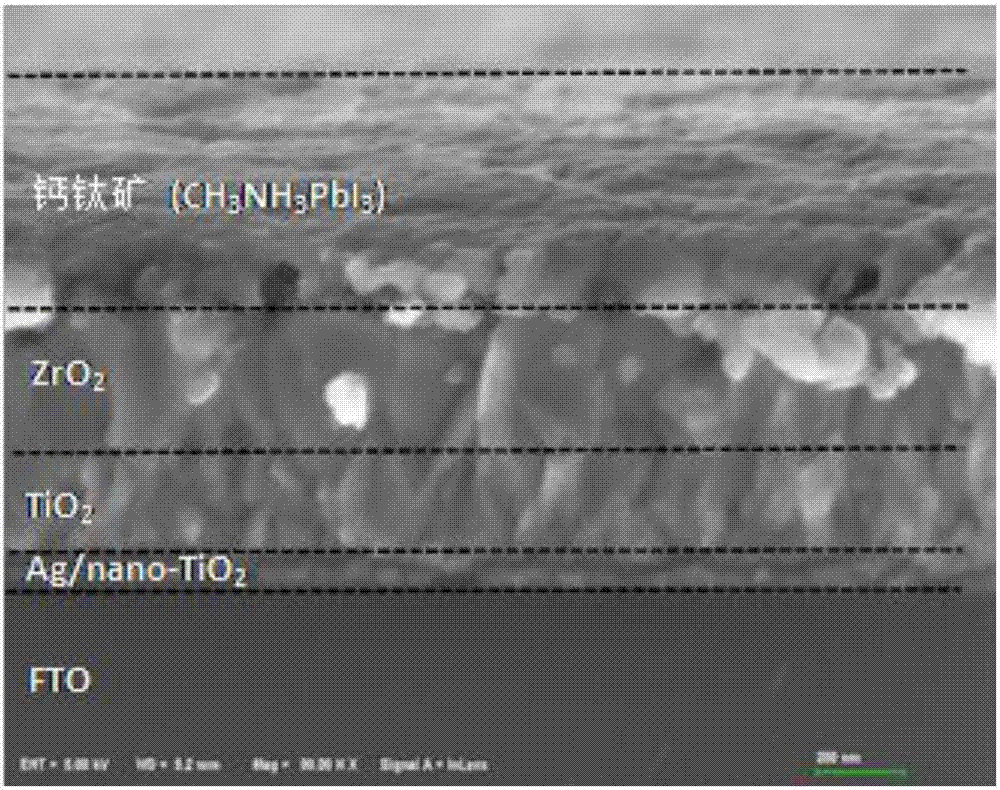

[0027] Then spin-coat titanium dioxide and zirconium dioxide on the obtained dense layer film at 3500 rpm for 20 s and 5000 rpm for 20 s, and anneal at a high temperature of 500 ° C for 30 min to obtain a 150 nm thick titanium dioxide layer and a 200 nm thick zirconium dioxide layer, that is, a mesoporous layer.

[0028] The perovskite film was formed by spin-coating lead iodide methylamine solution on the mesoporous layer and heating at 70 °C for 10 min.

[0029] Finally, the carbon counter electrode is print...

Embodiment 2

[0032] Silver nitrate and titanium dioxide are mixed at a molar ratio of silver to titanium of 1.5%, and a dense layer precursor solution is prepared in ethanol as a solvent. Subsequently, the method in Example 1 was used to sequentially prepare a silver / titania nanocomposite dense layer, a titanium dioxide and zirconium dioxide mesoporous layer, a perovskite layer and a carbon counter electrode.

Embodiment 3

[0034] Silver nitrate and titanium dioxide are mixed at a molar ratio of silver to titanium of 0.5%, and a dense layer precursor solution is prepared in ethanol as a solvent. Subsequently, the method in Example 1 was used to sequentially prepare a silver / titania nanocomposite dense layer, a titanium dioxide and zirconium dioxide mesoporous layer, a perovskite layer and a carbon counter electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com