Molybdenum nitride hydrodeoxygenation catalyst as well as preparation method and application thereof

A technology of deoxidation catalyst and molybdenum nitride, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, preparation of liquid hydrocarbon mixtures, etc., can solve the problems of product reduction, instability of active metal catalysts, expensive precious metals, etc. Achieve high selectivity, good hydrodeoxygenation effect, high reactivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

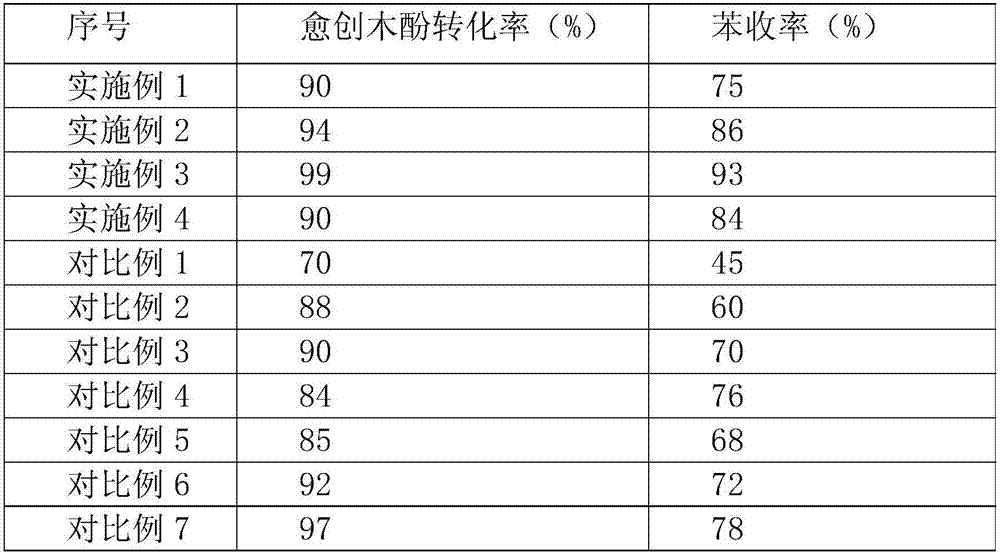

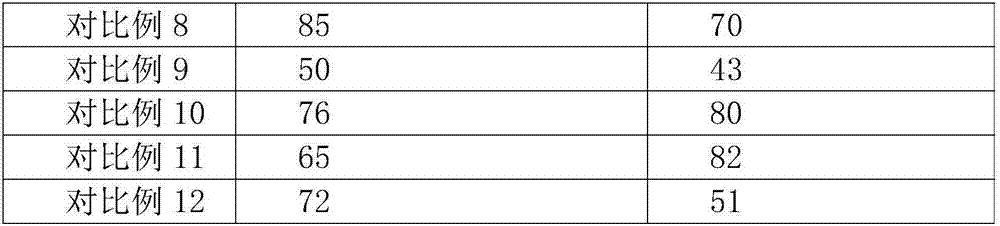

Examples

Embodiment 1

[0027] Catalyst preparation

[0028] Accurately weigh the carrier according to the water absorption of mesoporous carbon (MC) (the mesoporous carbon is treated with 2M concentrated hydrochloric acid in advance), and use it as an impregnated carrier after drying and roasting, and dissolve 0.27g ammonium molybdate in pure water to obtain an impregnating solution; The impregnation solution and the impregnation carrier were impregnated with equal volumes, impregnated at room temperature for 12 hours, and dried to obtain the precursor of the catalyst; the obtained precursor was subjected to a multi-stage temperature-programmed reaction; the temperature rate was 5°C / min in a hydrogen atmosphere from The room temperature is raised to 350°C, the temperature is raised from 350°C to 450°C at a temperature rate of 1°C / min, and the final temperature is raised from 450°C to 700°C at a temperature rate of 5°C / min. At this time, hydrogen is converted into ammonia. At the final temperature fo...

Embodiment 2

[0032] Replace 0.27g ammonium molybdate in embodiment 1 with 0.54g ammonium molybdate, and other steps are with embodiment 1.

Embodiment 3

[0034] Replace 0.27g ammonium molybdate in embodiment 1 with 0.82g ammonium molybdate, and other steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com