Novel environment-friendly high-molecular sand solidification agent and preparation method thereof

A technology of polymer and sand-fixing agent, applied in chemical instruments and methods, other chemical processes, applications, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effect of enhancing the growth trend, short reaction period, and beneficial to growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

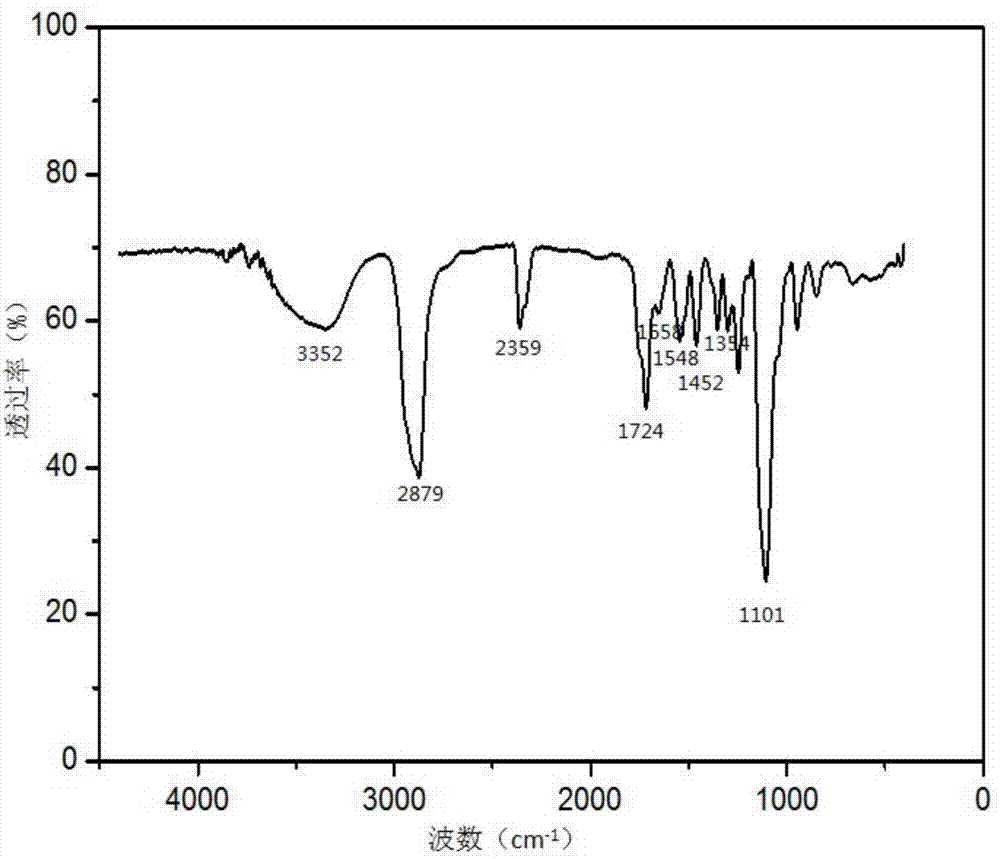

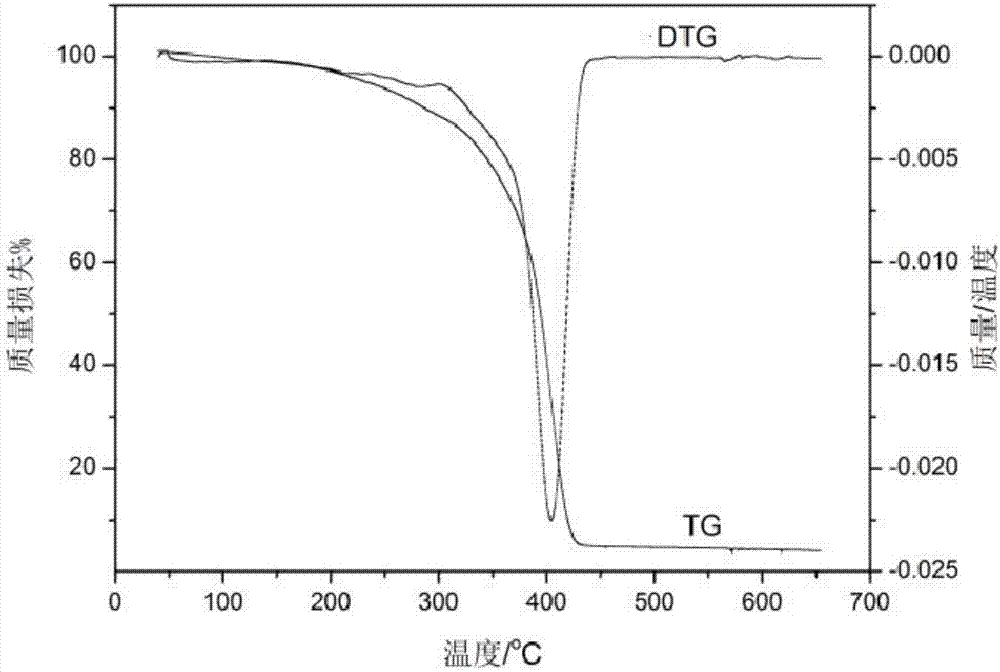

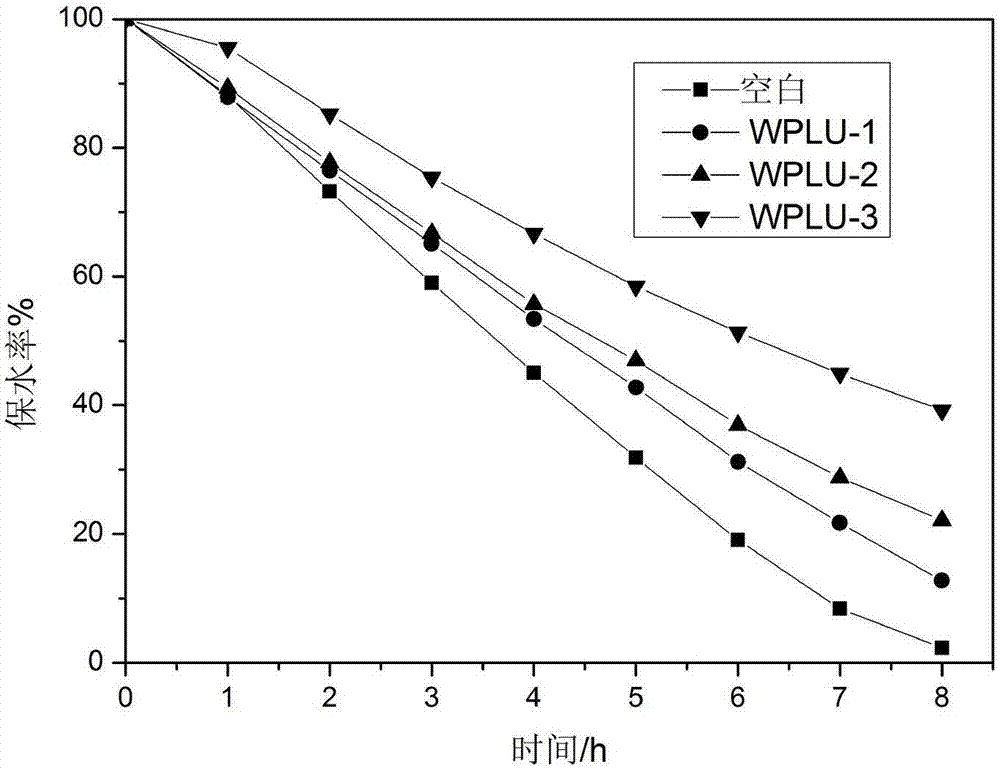

[0037] A preparation method of a novel environment-friendly polymer sand-fixing agent, which comprises the steps of:

[0038] (1) Preparation of polylactic acid: Take 20g of D, L-lactic acid and dilute sulfuric acid containing 1g of pure sulfuric acid into a three-necked flask, and distill under reduced pressure at 100°C for 1 hour to remove excess water. After the distillation is completed, maintain the three-necked flask The temperature in the flask was constant at 160°C, the vacuum degree was -0.06~-0.08Mpa, and the reaction was carried out under nitrogen for 2.5h. After the reaction was completed, the product was poured out from the three-necked flask while it was hot, and the temperature was lowered to room temperature. The crude product was treated with acetone. Dissolve, then precipitate with distilled water, filter, and vacuum-dry the filter cake to obtain polylactic acid;

[0039] (2) Weigh 20g of polyethylene glycol (PEG-2000), 3g of prepared polylactic acid and 5.5g...

Embodiment 2

[0043] A preparation method of a novel environment-friendly polymer sand-fixing agent, which comprises the steps of:

[0044] (1) Preparation of polylactic acid: Weigh 20g of D, L-lactic acid and dilute sulfuric acid containing 1g of pure sulfuric acid into a three-necked flask, and distill under reduced pressure at 100°C for 1h to remove excess water. The temperature in the three-necked flask was constant at 150°C, the vacuum degree was -0.06~-0.08Mpa, and the reaction was carried out under nitrogen gas for 2.5 hours. After the reaction was completed, the product was poured out of the three-necked flask while it was hot, and the temperature was lowered to room temperature. Dissolving, then precipitating with distilled water, filtering, and vacuum-drying the filter cake to obtain polylactic acid;

[0045](2) Weigh 20g of polyethylene glycol (PEG-2000), 3g of prepared polylactic acid and 5.5g of isophorone diisocyanate (PDI) into a three-necked flask with a reflux condenser and...

Embodiment 3

[0049] A preparation method of a novel environment-friendly polymer sand-fixing agent, which comprises the steps of:

[0050] (1) Preparation of polylactic acid: Weigh 20g of D, L-lactic acid and dilute sulfuric acid containing 1g of pure sulfuric acid into a three-necked flask, and distill under reduced pressure at 100°C for 1h to remove excess water. After the distillation is over, control The temperature in the three-necked flask was constant at 160°C, the vacuum degree was -0.06~-0.08Mpa, and the reaction was carried out under nitrogen for 2.5 hours. After the reaction was completed, the product was poured out of the three-necked flask while it was hot, and the temperature was lowered to room temperature. Dissolving, then precipitating with distilled water, filtering, and vacuum-drying the filter cake to obtain polylactic acid;

[0051] (2) Weigh 20g of polyethylene glycol (PEG-2000), 3g of prepared polylactic acid and 5.5g of isophorone diisocyanate (PDI) into a three-nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com