Preparation method of nano-composite hydrogel

A nanocomposite and hydrogel technology, which is applied in the field of nanocomposite hydrogel preparation, can solve the problems of toxicity and high consumption, and achieve the effects of good biocompatibility, high mechanical properties and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of nanocomposite hydrogel, comprises the following steps:

[0029] 1) Acid hydrolyzing chitin with a degree of acetylation of 0.94 to obtain a dispersion of chitin nano-whisker reinforcing agent;

[0030] 2) Mixing the chitin nano-whisker reinforcing agent dispersion liquid with the gelatin solution, and cooling to obtain a nano-composite hydrogel.

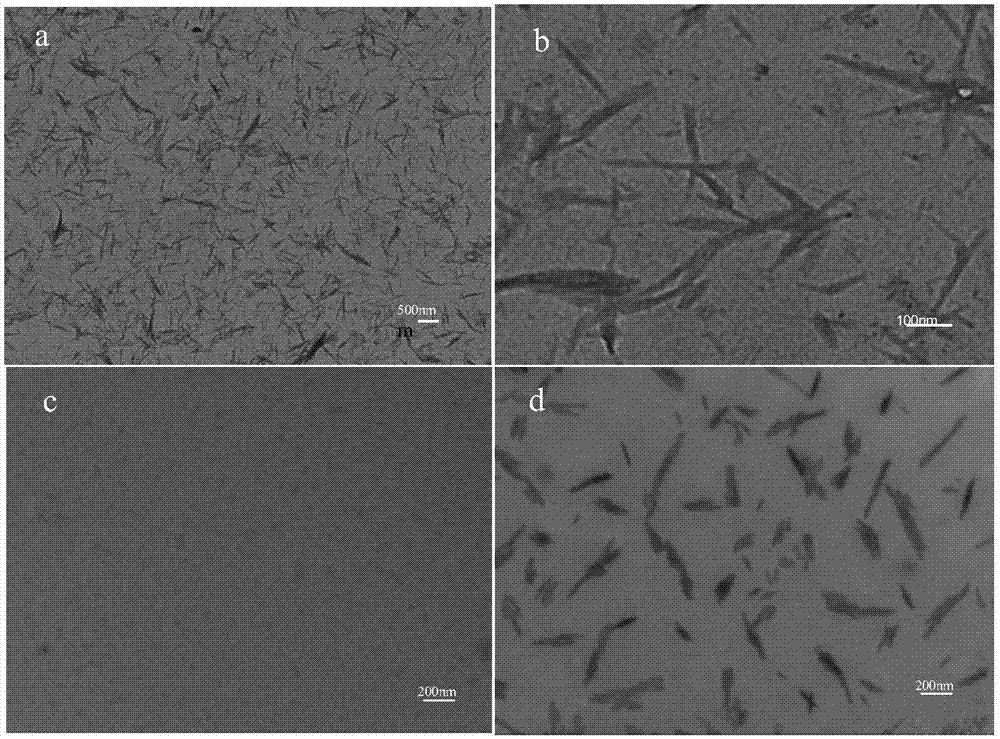

[0031] In the invention, the chitin with an acetylation degree of 0.94 is subjected to acid hydrolysis to obtain the chitin nano-whisker reinforcing agent. In the present invention, the step 1) acid hydrolysis adopts hydrochloric acid solution or sulfuric acid solution. When choosing hydrochloric acid solution to carry out acidolysis, the mass of described chitin and the volume ratio of hydrochloric acid solution are 1g:30mL, and the molar concentration of described hydrochloric acid solution is preferably 3mol / L; When adopting sulfuric acid solution to carry out acidolys...

Embodiment 1

[0036] 1. Chitin nano-whisker enhancer dispersion liquid: mix chitin with a degree of acetylation of 0.94 and hydrochloric acid at 1g:30mL, acidolysis temperature is 95°C, time is 10h, and the chitin nano-whisker enhancer is obtained by acidolysis Dispersions. Dialysis, centrifugal washing and drying were performed after the acid hydrolysis process.

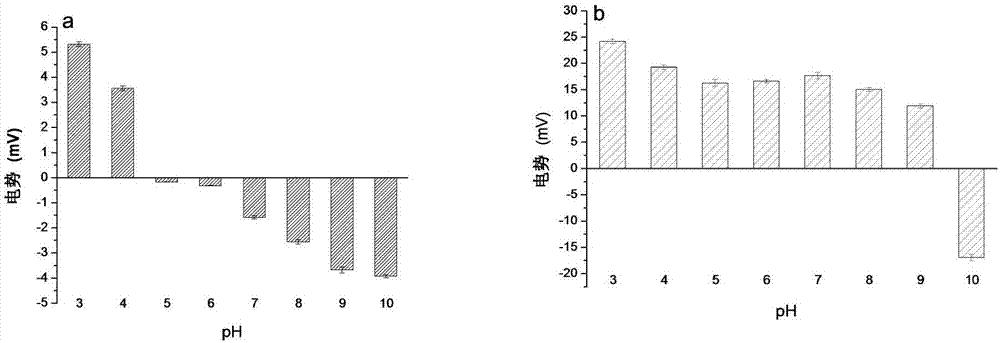

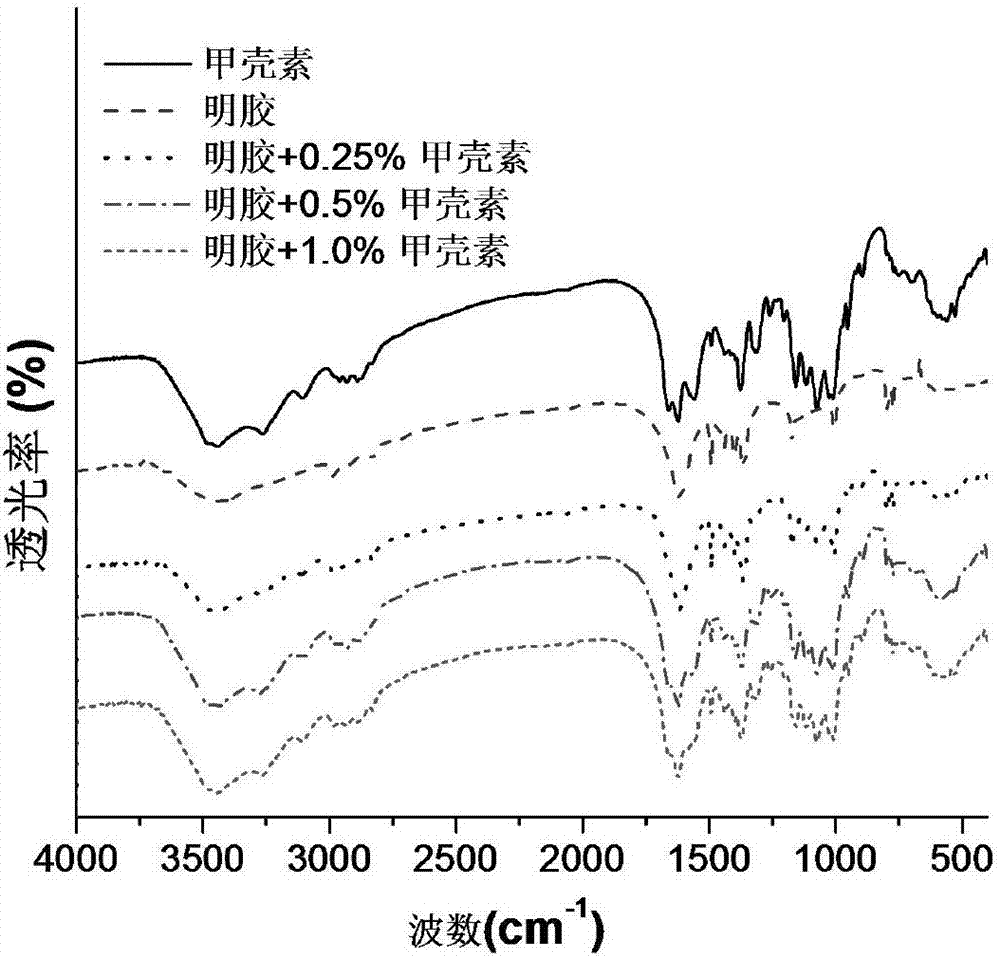

[0037] 2. Nano-composite hydrogel: prepare different concentrations of chitin nano-whisker enhancer dispersion liquid, add it to 14% gelatin solution (45°C), mix the two evenly, and finally nano-chitin accounts for 0.25% of the entire solution , 0.5% and 1.0%, and then the mixed solution was cooled at 4° C. for 12 hours to obtain a nanocomposite hydrogel. In addition, in order to study the influence of pH and ion concentration on the composite hydrogel, 1M NaOH or HCl is used to adjust the pH value to 3.0, 4.0, 5.0, 7.0, 8.0 or 9.0, and NaCl is used to adjust the ion concentration to 10, 30, 50, 70, 90mM.

Embodiment 2

[0039] Determination of gelation temperature and viscoelasticity: The dynamic rheological measurement of the nanocomposite hydrogel is measured using a strain-controllable rheometer, setting parameters: the temperature is 25°C, the rotor diameter and the parallel plate gap are 50mm and 1mm respectively , the frequency sweep is the angular frequency range 0.1-100rad / s, the constant strain is 1% (in the linear viscoelastic region), and the storage modulus (G') and loss modulus (G") are recorded. In order to observe the maturation of the gel sample The time sweep was determined, and the scan was performed at 10°C for 2.5h. The temperature sweep was decreased from 40°C to 10°C, and then increased to 40°C at a rate of 1°C per minute.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com