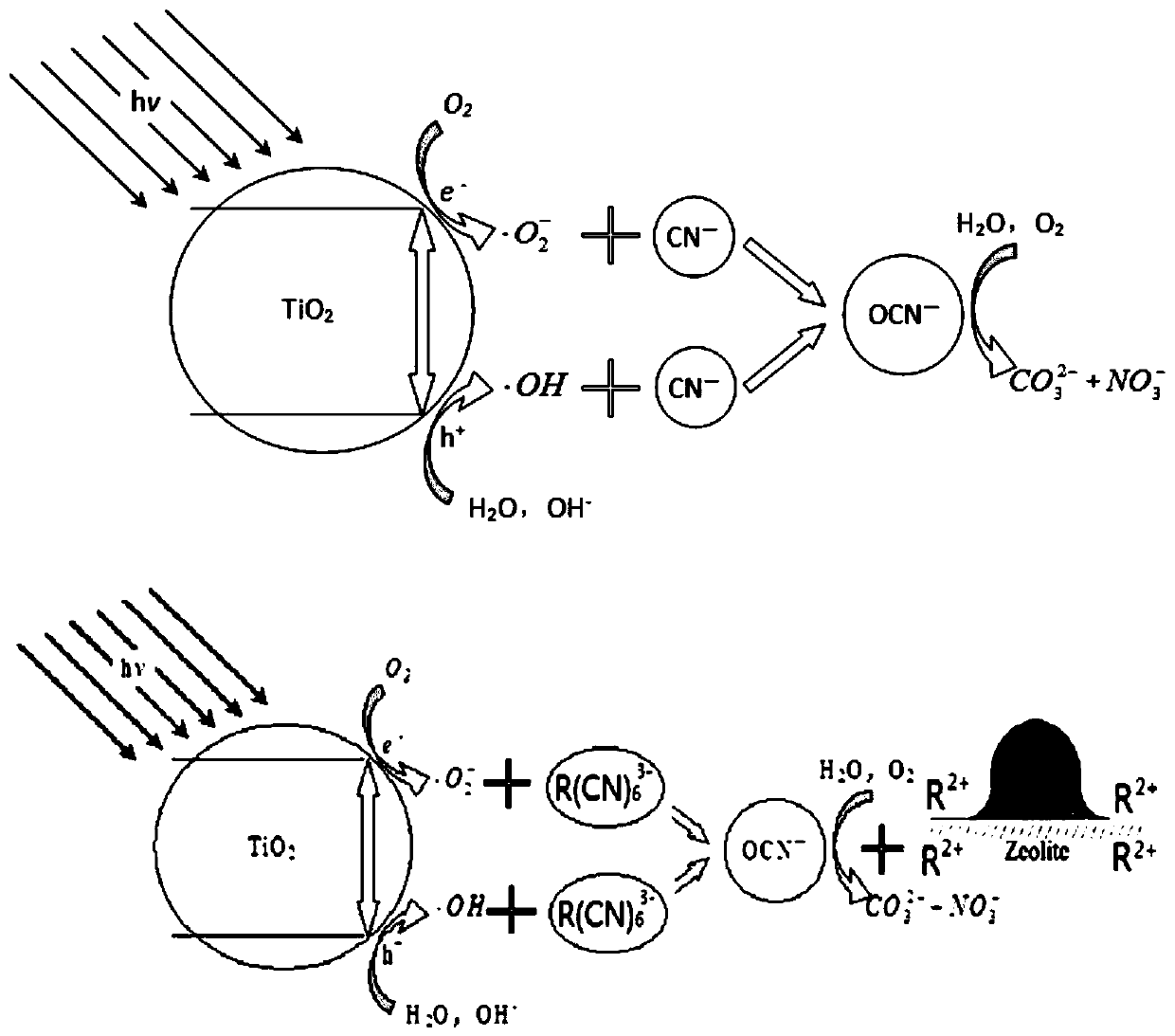

Silica/nano-titanium dioxide/silicalite composite material for treating cyanide-containing wastewater and its application

A nano-titanium dioxide and silicon dioxide technology, used in physical/chemical process catalysts, metallurgical wastewater treatment, water/sewage treatment, etc., can solve problems such as weak adsorption capacity, achieve increased surface area, large specific surface area, and ensure modification. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

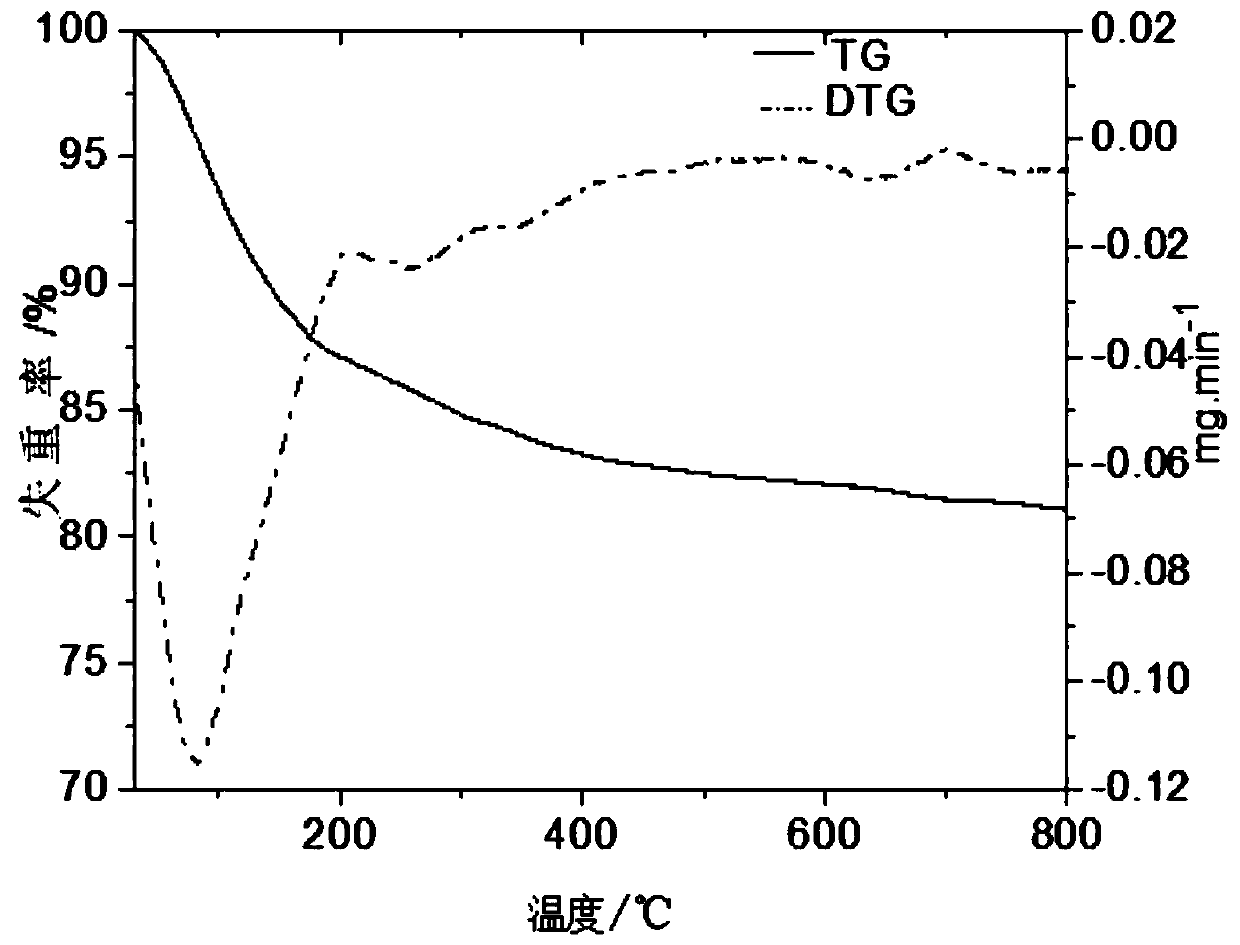

[0041] (1) Preparation of silicalite carrier

[0042] Mix silicalite and sodium hydroxide solution with a mass ratio of 1:4, put them in a three-necked flask, place in an electric heating mantle, and stir at 60°C for 36 hours. Add diethylenetriamine as a pore structure regulator during the stirring process , The dosage of diethylenetriamine is 1g / L to synthesize modified silicalite gel.

[0043] Put the modified silica zeolite gel in an autoclave with a pressure of 2atm, control the temperature at 100℃, react for 24 hours, filter, first wash with deionized water 3 times, then dry at 80℃ for 12 hours, and finally roast at 550℃4 A modified silicalite support was obtained within hours.

[0044] (2) Preparation of silica / nano-titanium dioxide / silica zeolite composite material

[0045] Dissolve butyl titanate, absolute ethanol, concentrated nitric acid, and lanthanum nitrate in water, stir at 300r / s for 30 minutes to obtain a milky white liquid, and evaporate to dryness at 80°C to obtain ...

Embodiment 2

[0051] (1) Preparation of silicalite carrier

[0052] Mix silicalite and sodium hydroxide solution with a mass ratio of 1:2, place them in a three-necked flask, place in an electric heating mantle, and stir at 90°C for 32 hours. Add AlCl during the stirring process 3 As a pore structure regulator, AlCl 3 The dosage is 3g / L to synthesize modified silicalite gel.

[0053] Put the modified silica zeolite gel in an autoclave with a pressure of 3atm, control the temperature at 60℃, react for 35 hours, filter, first wash with deionized water 3 times, then dry at 50℃ for 22 hours, and finally calcinate at 450℃8 A modified silicalite support was obtained within hours.

[0054] (2) Preparation of silica / nano-titanium dioxide / silica zeolite composite material

[0055] Dissolve butyl titanate, absolute ethanol, concentrated nitric acid, and lanthanum nitrate in water, stir at 400r / s for 25 minutes to obtain a milky white liquid, and evaporate to dryness at 50°C to obtain nano titanium dioxide pa...

Embodiment 3

[0060] (1) Preparation of silicalite carrier

[0061] Mix silicalite and sodium hydroxide solution with a mass ratio of 1:5, put them in a three-necked flask, place in an electric heating mantle, and stir at 120°C for 30 hours. Add FeCl during the stirring process 3 As a pore structure regulator, FeCl 3 The dosage is 5g / L to synthesize modified silicalite gel.

[0062] Put the modified silica zeolite gel in an autoclave with a pressure of 3.5 atm, control the temperature at 80°C, react for 30 hours, filter, wash with deionized water 4 times, dry at 60°C for 20 hours, and finally roast at 600°C The modified silicalite support was obtained in 6.5 hours.

[0063] (2) Preparation of silica / nano-titanium dioxide / silica zeolite composite material

[0064] Dissolve butyl titanate, absolute ethanol, concentrated nitric acid, and lanthanum nitrate in water, stir at 350r / s for 20 minutes to obtain a milky white liquid, and evaporate to dryness at 60°C to obtain nanometer titanium dioxide partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com