A method for preparing an efficient electron-transfer Cu-modified C/TiO2 photocatalytic reduction material

An electron transfer and photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problem of low catalytic efficiency, improve photocatalytic performance, realize noble metal substitution, and efficient utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

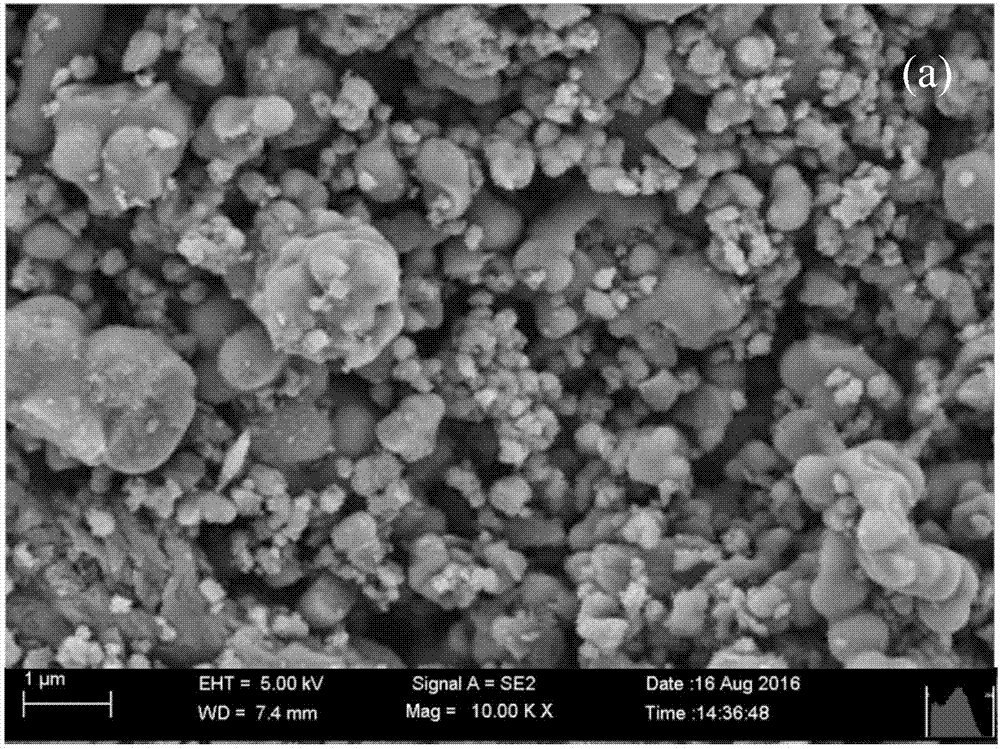

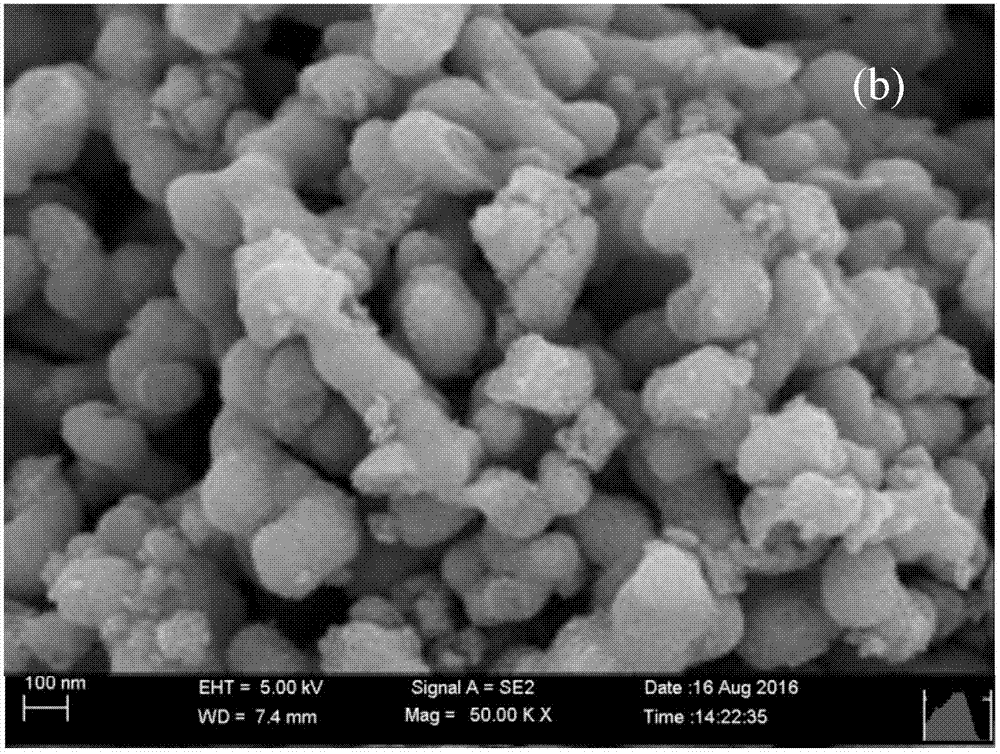

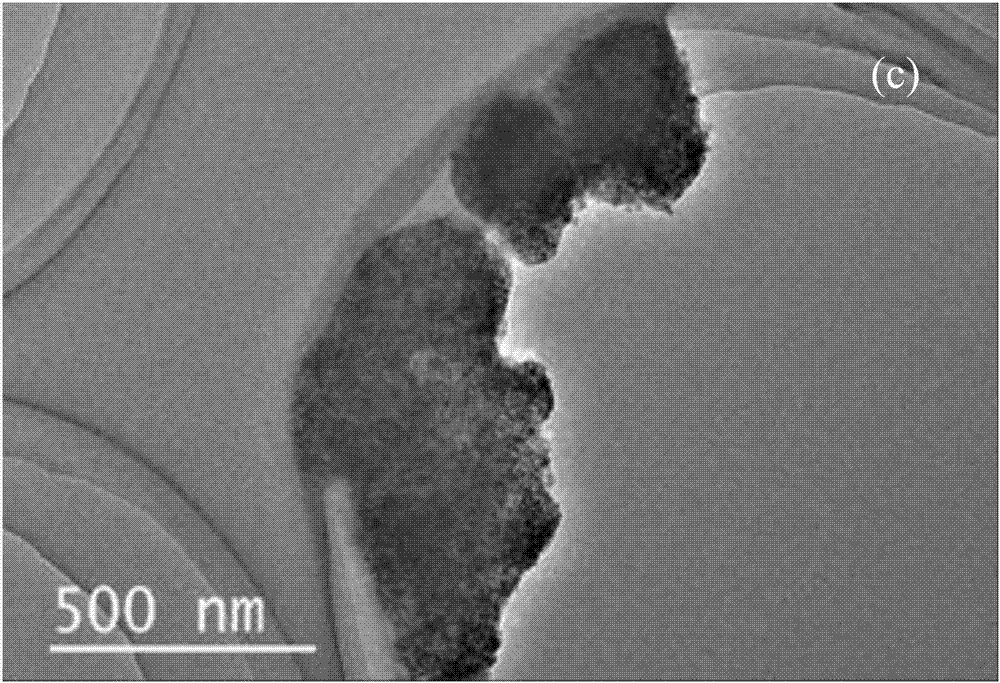

Image

Examples

Embodiment 1

[0034] (1) Preparation of C / TiO by sol-gel method 2

[0035] Take 1 mL of deionized water and add it to 25 mL of tetrabutyl titanate to form a sol-gel, stir it magnetically at room temperature for 4 hours, filter and put it in an oven to dry. Grind and dry the filter cake, put it into a muffle furnace for calcination at 400°C for 2 hours, and obtain C / TiO after cooling 2 catalyst;

[0036] After testing, the prepared C-doped TiO 2 The carbon content is 1.1%.

[0037] (2) Preparation of CuO by photoreduction deposition method x -C / TiO 2

[0038] Get the C / TiO prepared in 0.6g step (1) 2 Catalyst and 3.7mL 0.01mol / L CuCl 2The solution was mixed and ultrasonicated for 10 minutes, 5 mL of glycerol was added, and deionized water was added to make the total volume of the mixed solution 100 mL, and the solution was illuminated by a xenon lamp for 2 hours (the power of the xenon lamp was 300 W, and the wavelength range of its emission spectrum was 350-780 nm). Before light ir...

Embodiment 2

[0041] (1) Preparation of C / TiO by sol-gel method 2

[0042] Take 3 mL of deionized water and add it to 25 mL of tetrabutyl titanate to form a sol-gel, stir it magnetically at room temperature for 8 hours, filter and put the filter cake in an oven to dry. Grind and dry the filter cake, put it into a muffle furnace for calcination at 400°C for 2 hours, and obtain C / TiO after cooling 2 catalyst;

[0043] After testing, the prepared C-doped TiO 2 The carbon content is 3.5%.

[0044] (2) Preparation of CuO by photoreduction deposition method x -C / TiO 2

[0045] Get the C / TiO prepared in 0.6g step (1) 2 Catalyst and 7.2mL 0.01mol / L Cu(NO 3 ) 2 The solution was mixed and ultrasonicated for 10 minutes, 5 mL of glycerol was added, and deionized water was added to make the total volume of the mixed solution 100 mL, and the solution was illuminated by a xenon lamp for 2 hours (the power of the xenon lamp was 300 W, and the wavelength range of its emission spectrum was 350-780 n...

Embodiment 3

[0048] (1) Preparation of C / TiO by sol-gel method 2

[0049] Take 5 mL of deionized water and add it to 25 mL of tetrabutyl titanate to form a sol-gel, stir it magnetically at room temperature for 12 hours, filter and put the filter cake in an oven to dry. Grind and dry the filter cake, put it into a muffle furnace for calcination at 400°C for 2 hours, and obtain C / TiO after cooling 2 catalyst;

[0050] After testing, the prepared C-doped TiO 2 The carbon content is 4.6%.

[0051] (2) Preparation of CuO by photoreduction deposition method x -C / TiO 2

[0052] Get the C / TiO prepared in 0.6g step (1) 2 Catalyst and 14.3mL 0.01mol / L CuSO 4 The solution was mixed and ultrasonicated for 10 minutes, 5 mL of glycerol was added, and deionized water was added to make the total volume of the mixed solution 100 mL, and the solution was illuminated by a xenon lamp for 2 hours (the power of the xenon lamp was 300 W, and the wavelength range of its emission spectrum was 350-780 nm). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com