Movable straw compact forming equipment in field

A molding equipment and mobile technology, applied in the direction of packaging/bundling items, application, presses using rotating pressure members, etc., can solve the problems that are not conducive to long-term stability of straw molding and moisture retention, unfavorable transportation and storage, green preservation and moisture storage , Unable to match the field operation system and other problems, to avoid excessive extrusion resistance, prolong the continuous operation time, reduce the number and frequency of shutdown maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to more fully explain the implementation of the present invention, implementation examples of the present invention are provided. These implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

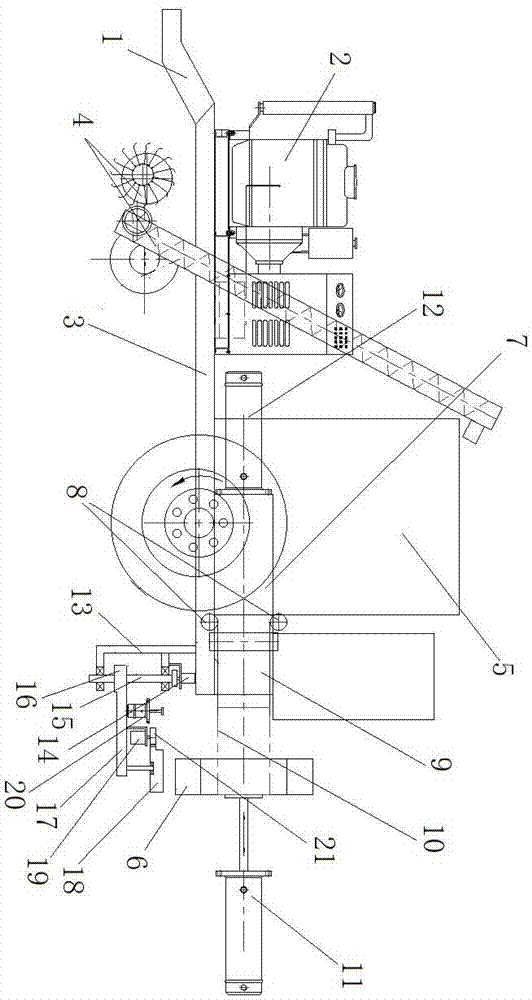

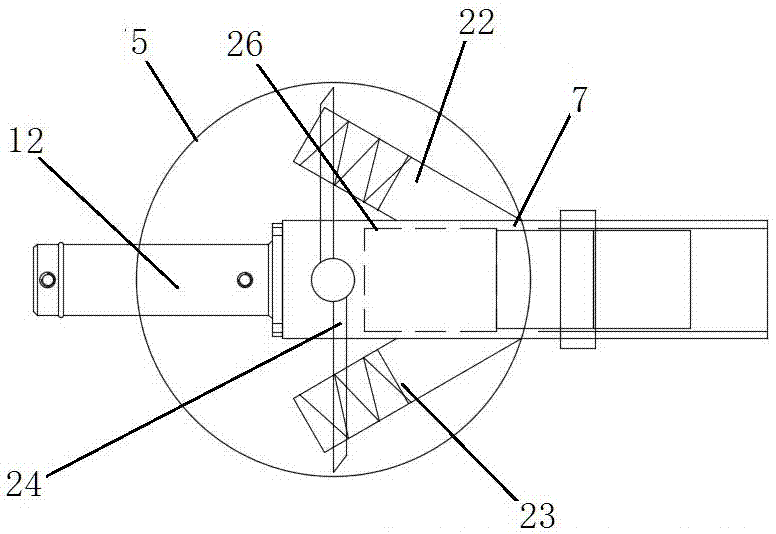

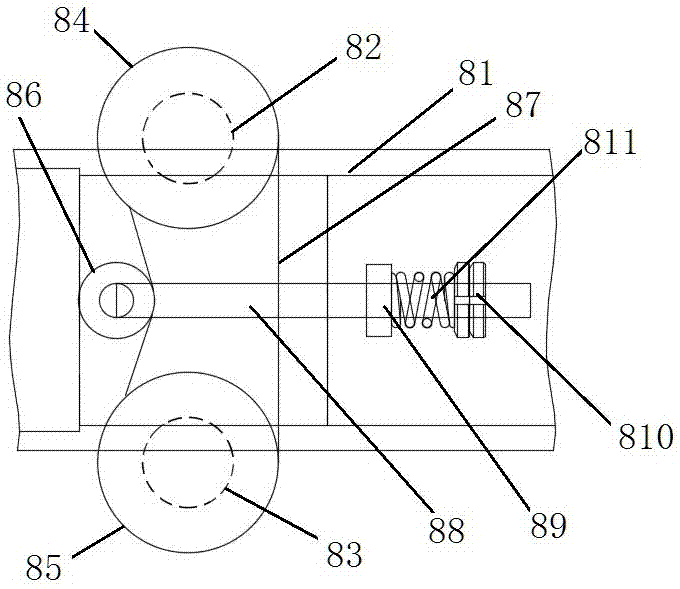

[0022] A further detailed explanation of the present invention will be given in conjunction with the accompanying drawings. In the accompanying drawings, each mark is: 1: traction mechanism; 2: power device; 3: traction platform; 4: straw picking and conveying mechanism; 5: buffer bin; Wrapping mechanism; 61: guide roller; 62: rope frame and rope tensioner; 63: film frame and film tensioner; 64: C-shaped swivel; 7: forming room; 8: roller throat mechanism; 81: shape retention Channel housing; 82: upper squeeze roller; 83: lower squeeze roller; 84: upper right guide wheel; 85: lower right guide wheel; 86: right adjustment wheel; 87: right tightening chain / belt; 88: right adjustment screw ;89: Right gui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com