Fine purification technology of graphite

A fine purification and process technology, which is applied in the field of graphite fine purification technology, can solve the problems of low purity of graphite products, difficulty in control, and easy volatilization of hydrofluoric acid, etc., and achieve the effect of avoiding ultra-high temperature operation difficulties, avoiding melting adhesion, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

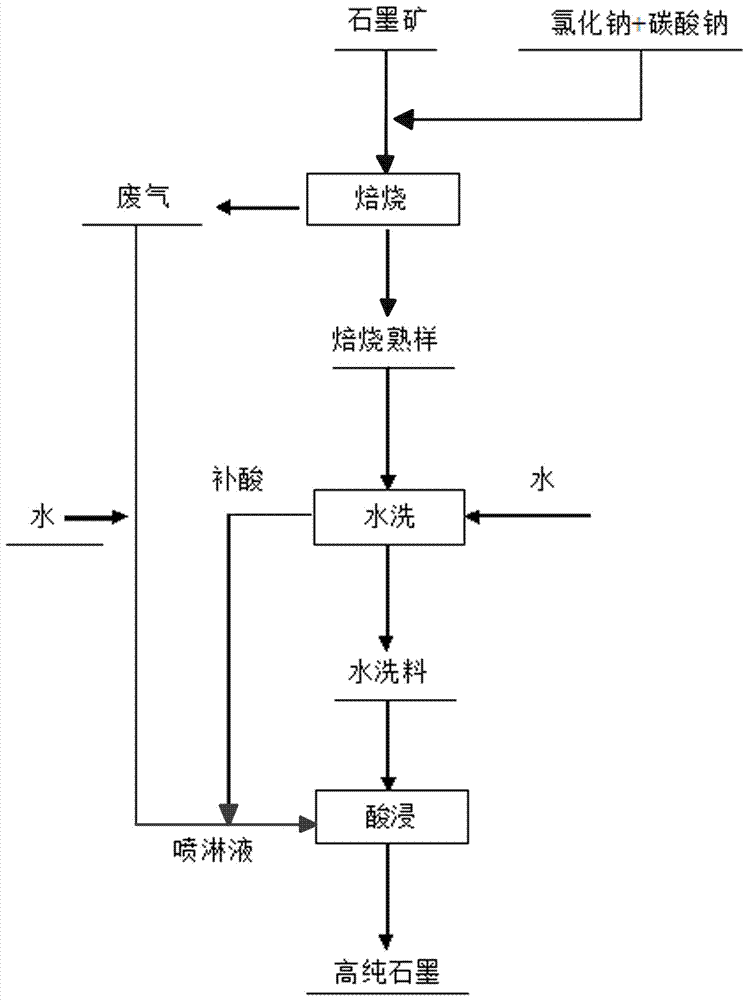

Embodiment 1

[0021] Mix graphite ore with sodium chloride and sodium carbonate evenly according to the mass ratio of 86~90:5~7:5~7, and then put the mixed sample in the roasting furnace, under the condition of heating rate of 10~15°C / min Raise to the roasting temperature, and roast at a roasting temperature of 750-800°C for 60-120 minutes. After roasting, roasted samples and waste gas are obtained. The waste gas is sprayed with water through the spray pipe to obtain spray liquid for subsequent acid leaching operations. Wash the roasted samples with water, and stir for 60-90 min under the conditions of liquid-solid ratio of 5-10 mL:1 g, leaching temperature of 40-50°C and stirring intensity of 100-150 r / min. Separate the washing liquid and the washing material. After adding hydrochloric acid, the water washing liquid is mixed with the spraying liquid for the subsequent acid leaching operation; the washing material is subjected to acid leaching operation, when the concentration of hydrochlori...

Embodiment 2

[0023] Mix the graphite ore with sodium chloride and sodium carbonate evenly according to the mass ratio of 84~88:6~8:6~8, then put the mixed sample in the roasting furnace, under the condition that the heating rate is 10~15°C / min Raise to the roasting temperature, and roast at a roasting temperature of 720-750°C for 60-120 minutes. After roasting, roasted samples and waste gas are obtained. The waste gas is sprayed with water through the spray pipe to obtain spray liquid for subsequent acid leaching operations. The roasted samples were washed with water, and stirred for 60-90 min under the conditions of liquid-solid ratio of 5-10 mL:1 g, leaching temperature of 50-60 °C and stirring intensity of 150-200 r / min. Separate the washing liquid and the washing material, and the water washing liquid is mixed with the spraying liquid after adding hydrochloric acid for the subsequent acid leaching operation; the washing material is subjected to acid leaching operation, when the concentr...

Embodiment 3

[0025] Mix the graphite ore with sodium chloride and sodium carbonate evenly according to the mass ratio of 80~84:8~10:8~10, then put the mixed sample in the roasting furnace, under the condition that the heating rate is 10~15°C / min Raise to the roasting temperature, and roast at a roasting temperature of 680-720°C for 60-120 minutes. After roasting, roasted samples and exhaust gas are obtained. The exhaust gas is sprayed with water through the spray pipe to obtain spray liquid for subsequent acid leaching operations. The roasted samples were washed with water, and stirred for 60-90 min under the conditions of liquid-solid ratio of 5-10 mL:1 g, leaching temperature of 60-70 °C and stirring intensity of 200-300 r / min. Separate the washing liquid and the washing material. After adding hydrochloric acid, the water washing liquid is mixed with the spraying liquid for the subsequent acid leaching operation; the washing material is subjected to acid leaching operation, when the conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com