Agriculture waste cyclic utilization system

A technology of agricultural waste and subsystems, applied in the field of agricultural waste recycling system, can solve the problems of ineffective utilization, time-consuming, and large land occupation, and achieve the effects of efficient recycling, high resource utilization rate, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

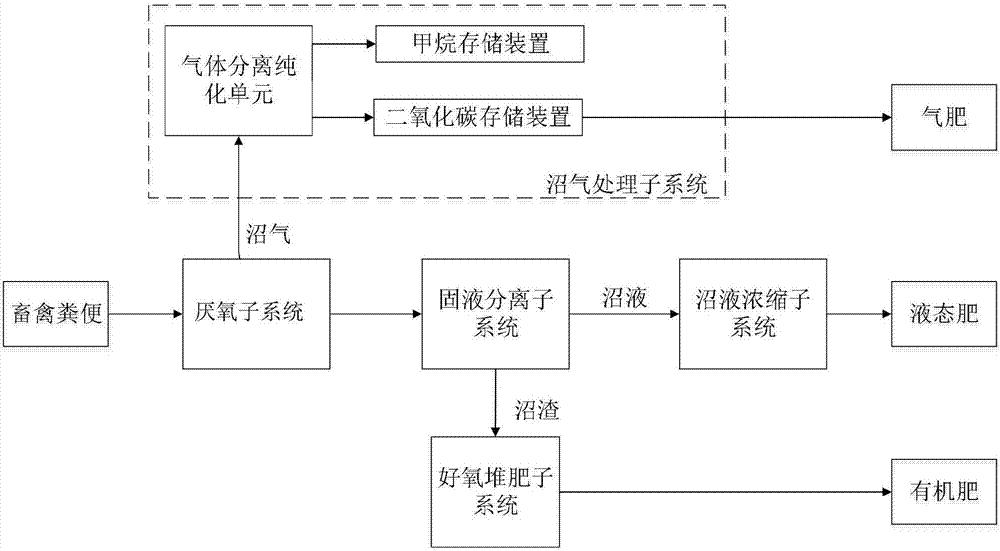

[0027] An agricultural waste recycling system, including anaerobic subsystem, biogas treatment subsystem, solid-liquid separation subsystem, biogas slurry concentration subsystem and aerobic composting subsystem, wherein,

[0028] The anaerobic subsystem uses the anaerobic fermentation of livestock and poultry manure to produce biogas, which includes an anaerobic reactor, which has a biogas outlet and a solid-liquid outlet; of course, as raw materials for biogas fermentation, in addition to livestock and poultry manure in agriculture, etc. , can also include organic agricultural waste such as crop stalks, fallen leaves of trees, etc. After these agricultural wastes are collected, biogas is produced through anaerobic fermentation of the anaerobic subsystem, and biogas residue and biogas slurry are produced.

[0029] The biogas treatment subsystem includes a gas separation and purification unit, which is connected to the biogas outlet of the anaerobic reactor to realize the puri...

Embodiment 2

[0035] An agricultural waste recycling system based on Example 1, the anaerobic subsystem also includes a hydrolysis tank and a primary anaerobic reactor, the hydrolysis tank is connected to the primary anaerobic reactor through a peristaltic pump, and the primary anaerobic reactor passes through a peristaltic The pump is connected to the anaerobic reactor; the primary anaerobic reactor has a biogas outlet, and the biogas outlet of the primary anaerobic reactor is connected to a gas separation and purification unit.

[0036] Among them, the total volume of materials in the anaerobic reactor is 40-50% of the total volume of materials in the primary anaerobic reactor. After the materials are fermented in the anaerobic reactor for 7-10 days, the materials are transported to the solid-liquid outlet through the solid-liquid outlet. Separation subsystem; then pump 40-50% of the material in the primary anaerobic reactor into the anaerobic reactor through a peristaltic pump; then pump ...

Embodiment 3

[0040] An agricultural waste recycling system based on embodiment 1 or 2, wherein the solid-liquid separation subsystem includes a settling tank and a dehydrator, and the feed inlet of the settling tank is connected with the solid-liquid outlet of the anaerobic reactor through a peristaltic pump, The upper end of the settling tank is provided with a biogas slurry outlet, and the lower end of the settling tank is provided with a middle biogas sludge outlet; the feed port of the dehydrator is connected to the biogas slurry outlet of the settling tank, which is provided with a biogas slurry outlet and a biogas residue outlet; the biogas slurry outlet of the settling tank and the dehydration The biogas slurry outlet of the dehydrator is connected with the biogas slurry concentration subsystem; the biogas residue outlet of the dehydrator is connected with the aerobic composting subsystem. In this way, biogas residue and biogas slurry can be separated efficiently, not only can fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com