Method for producing p-xylene, o-xylene and 1,2,4-trimethylbenzene from coal-based raw materials

A technology of p-xylene and p-trimethylbenzene, which is applied in chemical instruments and methods, bulk chemical production, purification/separation of hydrocarbons, etc., can solve the problems of poor economy and high cost, and achieve coking delay, high activity, The effect of good reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

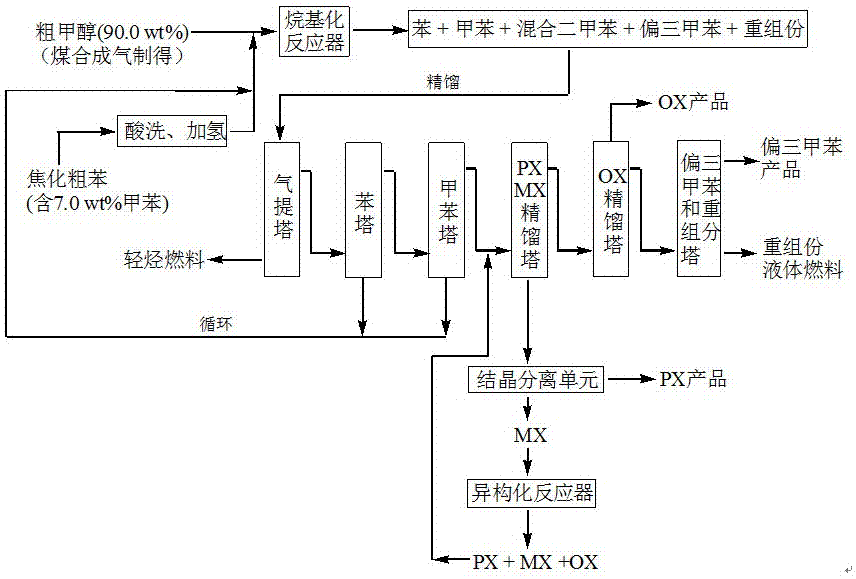

[0035] figure 1 Shown is a typical process flow of the method for producing p-xylene, o-xylene and mesitylene from coal-based raw materials in the present invention. Using crude methanol (90%) produced from coal synthesis gas and coked crude benzene (containing 91.6% benzene, 7.0 wt% toluene, 1.3 wt% xylene and 0.1 wt% other impurities) as raw materials, the coked crude benzene was washed with sulfuric acid, Hydrogenation pretreatment (NiO-MoO 3 and Co-MoO 3 Catalyst, fixed bed), and the crude methanol enters the alkylation reactor (fluidized bed) for catalytic reaction, and the obtained products are mainly toluene, mixed xylene, trimethylbenzene, a small amount of heavy aromatics and light hydrocarbons. The above products enter the rectification system together, and first pass through the stripping tower to separate light hydrocarbons as fuel for the device; the heavy components flowing out of the stripping tower pass through the benzene tower to separate and obtain unconve...

Embodiment 2

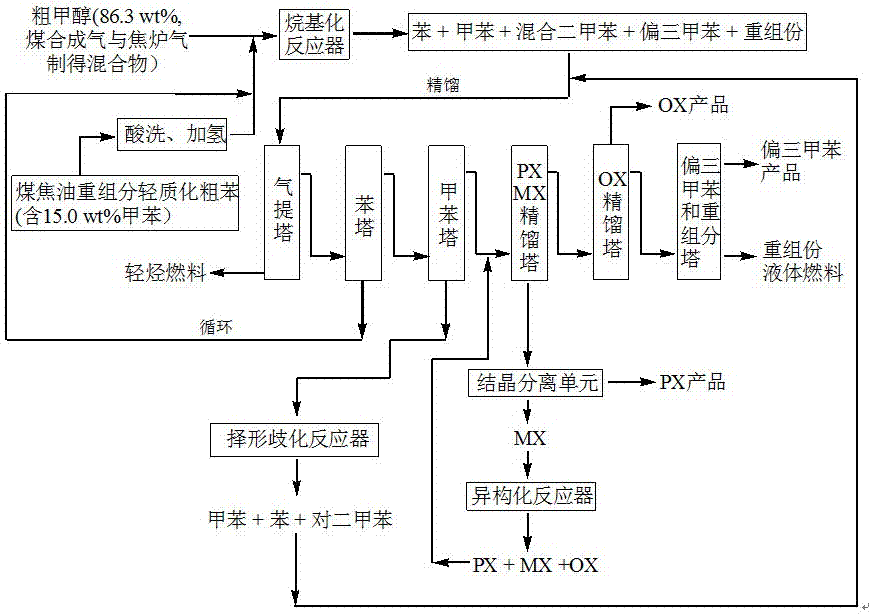

[0038] The differences between this example and Example 1 are: 1) The raw material of coal-based methanol is crude methanol produced from coal coke oven gas (methanol content 93.0 wt%); 2) The raw material of coal-based benzene is obtained by lightening heavy components of coal tar Crude benzene, containing 79.8% benzene, 15.0 wt% toluene, 5.0 wt% xylene and 0.2 wt% other impurities; 3) The alkylation reactor uses a fixed-bed reactor. 4) The catalyst used in the alkylation reaction is 0.02% Ce 2 o 3 Nanoacicular ZSM-5 molecular sieve modified with 0.1% MgO, with an external specific surface area of 98m 2 / g, the number of acid sites on the outer surface accounts for 37% of the total number of acid sites, and the number of weak and moderately strong acid sites accounts for 98.1% of the total number of acid sites; the alkylation reaction conditions are: the moles of methanol and aromatics (benzene+toluene) The ratio is 1:1, the reaction pressure is 2.0 MPa, the reaction temp...

Embodiment 3

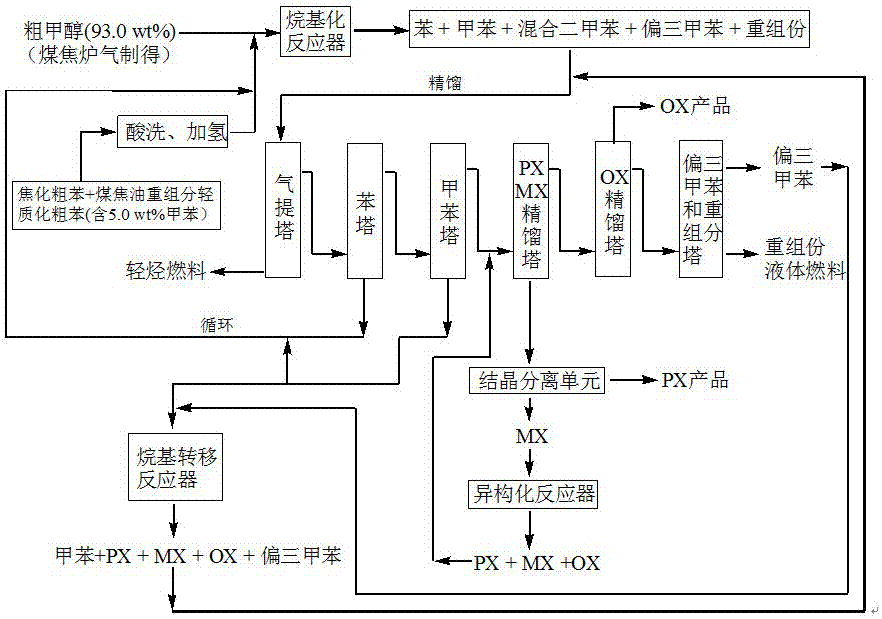

[0040] The differences between this example and Example 1 are: 1) coal-based benzene is coking benzene (containing 99.79% benzene, 1.0 wt% toluene, 0.2wt% xylene and 0.01 wt% other impurities); 2) coal-based methanol raw material Crude methanol (methanol content: 80.0 wt%) was produced from coal synthesis gas; 3) The alkylation reactor was a moving bed reactor. 4) The catalyst used in the alkylation reaction is a sheet-like MCM-49 / nano-Beta composite molecular sieve modified with 5.0%CdO and 5.0%CuO, with an external specific surface area of 91 m 2 / g, the number of acid sites on the outer surface accounts for 32% of the total number of acid sites, and the number of weak and moderately strong acid sites accounts for 95.1% of the total number of acid sites; the alkylation reaction conditions are: the moles of methanol and aromatics (benzene and toluene) The ratio is 1:2, the reaction pressure is 5.0 MPa, the reaction temperature is 700°C, the molar ratio of water to raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com